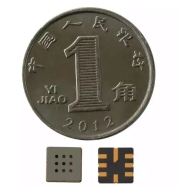

GM-402B MEMS Combustible Gas Sensor

- • Detection: CH4, 0~1000PPM

- • Detection: C3H8, 0~5000PPM

- • Usage: Gas leak detection for mobile phones, computers and other consumer electronics applications

We're here to help: Easy ways to get the answers you need.

中文站

中文站 Русский

Русский 한국인

한국인