| Target: | hydrogen H2 gas |

| Model: | CMV-2021D |

| Detection range: | 0~100 %LEL |

| Detection principle: | Catalytic combustion effect |

| Characteristics: | The bridge output is linear,Quick response |

| Response time: | ≤2s |

CMV-2021D Manual download

Get Price Whatsapp

Description

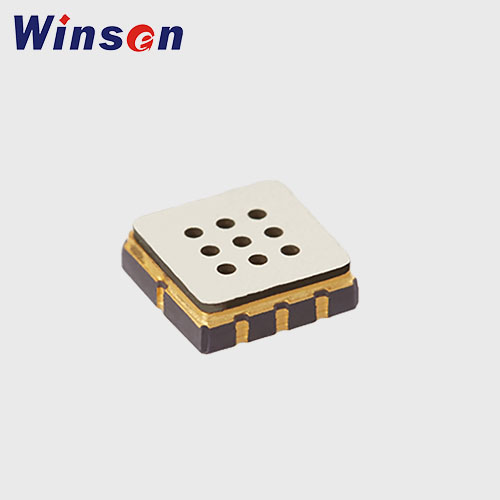

CMV-2021D catalytic hydrogen sensor adopts MEMS process, works according to the principle of catalytic combustion effect, and is paired by a detection element and a compensation element to form an arm of the bridge, when the resistance of the detection element increases, the output voltage of the bridge changes, the voltage variable increases proportionally with the increase of hydrogen concentration, and the compensation element plays a reference and temperature and humidity compensation role.

Application

- Hydrogen-powered vehicle

- Hydrogen energy preparation

- Energy storage battery / power station

- Hydrogen energy transport and use

- Hydrogen detection in other scenarios

Features

- The bridge output is linear

- Quick response

- Good repeatability and selectivity

- Good stability and reliability

- Low power consumption

- Excellent anti-interference ability

Specifications

| Model | CMV-2021D | |

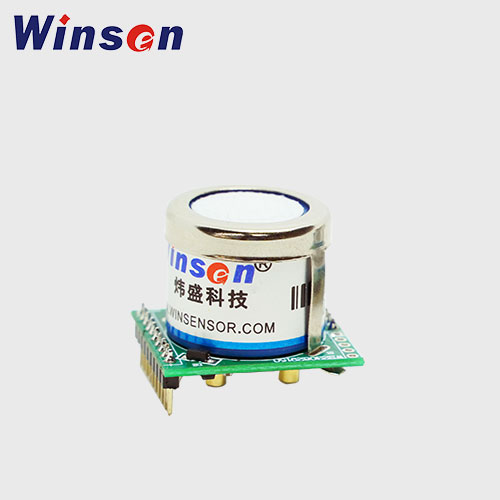

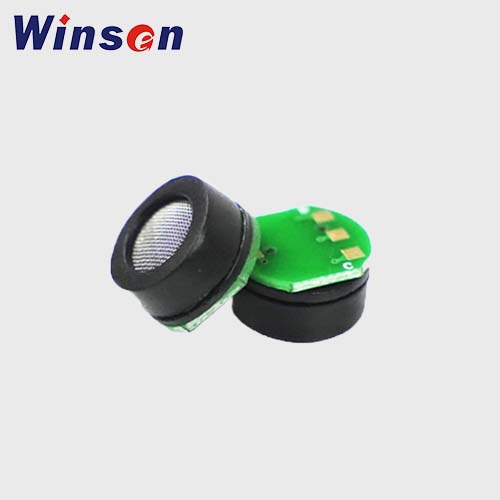

| Sensor Type | MEMS Catalytic | |

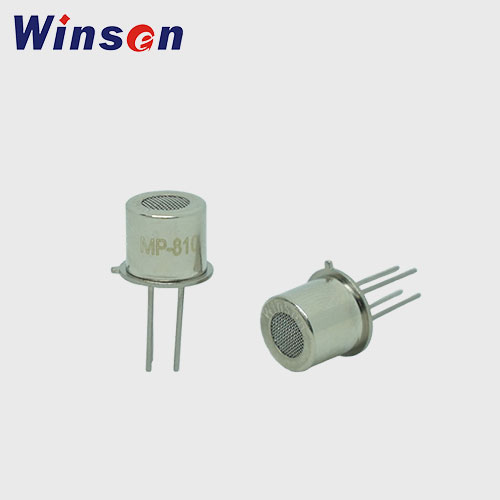

| Standard Encapsulation | Plastic Encapsulation | |

| Working voltage(V) | 3.0±0.1 | |

| Working current(mA) | 14±1.0 | |

| Sensitivity (mV) | 1% H2 | 30~60 |

| Linearity | ≤5% | |

| Measuring range(%LEL) | 0~100 | |

| Startup time in air | ≤0.5s | |

| Response Time (90%) | ≤2s | |

| Recovery Time (90%) | ≤1s | |

| Working Environment | -40~+85℃,less than 95%RH | |

| Storage Environment | -40~+85℃,less than95%RH | |

* The description and specifications might be changed without notice. Please contact us for the latest information before placing orders.

Technical Support:

Customized technical design and function, LOGO and package are available without extra charge (including molding fee) for mass volume.

The sensors don't have sleeping mode. It can be set in program if needed.

All Winsen products go through strict inspections and tests to make sure they are 100% qualified before shipping out.

The sensor has been fully tested (not calibrated) before leaving the factory, but the module will be calibrated before leaving the factory.

However, after transportation and storage, the environment conditions change, and the surface of the sensor absorbs moisture, mixed gas, pollution matters, etc. It is recommended that customers perform aging and calibration after sensors become stable according to the program and use occasions of the whole device.

15﹪-90﹪RH without condensation,greater or less than this range or long-term high temperature and high humidity will affect the life of the sensor.

Our sensors are certified with CE, 3C, ROHS, anti-explosion, fire prevention, and coal mining safety according to different applications. And we provide assistance for new certification.

Many factors can cause the sensor to fail such as broken wires in transportation, poisoning, falling off of the sensitive material, damage to the heating wire (device), etc. Please find specific cause in each category with Winsen’s aftersales.

Winsen provides professional consultation and service before and after sales. We will recommend the best fitting sensor for your demand. If you have any problem, don’t hesitate to email us to sales@winsensor.com

Due to high volume of daily incoming emails and time zone difference, we may not be able to reply your emails immediately. But we will reply to your inquiry in 24 business hours.