Natural Gas LPG Gas Use Safety in Home and Restaurants

Natural gas which content is mainly methane CH4 is a clean energy although it produce greenhouse gas; it’s greener with low carbon emission than other fossil fuels. Therefore natural gas and LPG gas are widely used in home and commercial sites like restaurants. But its non-complete combustion will produce toxic gas-carbon monoxide gas. And its feature of flammable and explosive has caused many safety problems and tragedies.

There are some combustible gases commonly used in our life such as natural gas, LPG gas, coal gas, marsh gas... When the content in closed room reaches certain level, there will be risk of explosion once only a spark appears.

Accident cases:

A gas explosion in central Paris on Wednesday, June 21, 2023. The Paris prosecutor said that early signs indicate that the gas explosion came from within the building. A part of the building collapsed following the blast and fire. At least 37 injured and 4 who are in a critical condition after the blast which was suspected to be caused by gas leakage in the building.

The same day, an explosion in a barbecue restaurant in Yinchuan caused 31 death and 7 injuries. Investigation revealed the cause was unauthorized replacement of the pressure valve connected to the liquefied gas tank, resulting in the rapid leakage of LPG gas in the tank and the massive blast..

More gas safety news can be found in global wide.

The most critical point to prevent and avoid gas explosions is to be able to know in time whether natural gas leaks. Usually, smelling, smearing soapy water and installing gas alarms can be used to identify gas leaks. Natural gas is smelless, the gas company will add harmless odor for leakage alarm purpose. Compared with the first two methods, installing gas alarms can achieve 7*24 hours of uninterrupted and more reliable Monitoring and early warning. Today, the necessity and importance of gas alarm installation has been increasingly recognized by the public. Gas leakage alarm devices are installed in gas use places, and protective measures are taken in time when danger warnings occur to eliminate potential safety hazards.

The core function of the gas alarm is the real-time monitoring and alarm of combustible gas leakage, which is mainly realized by the gas sensor inside. The catalytic combustion gas sensor has a fast response speed, and the output of the sensor is almost proportional to the gas concentration until the lower explosion limit concentration (LEL), so the accuracy and repeatability are high, and it is suitable for combustible gases such as industrial and commercial gas, liquefied petroleum gas, coal gas, and alkanes concentration detection.

Type of Flammable/Combustible Gas Alarms

- Installation way: fixed type; portable type.

- Use occasions: explosion proof-commerical/mining site; common type-home use

- Detection gas: LPG gas alarm; natural gas alarm; coal gas alarm;

- carbon monoxide CO- produced gas from non-combustion.

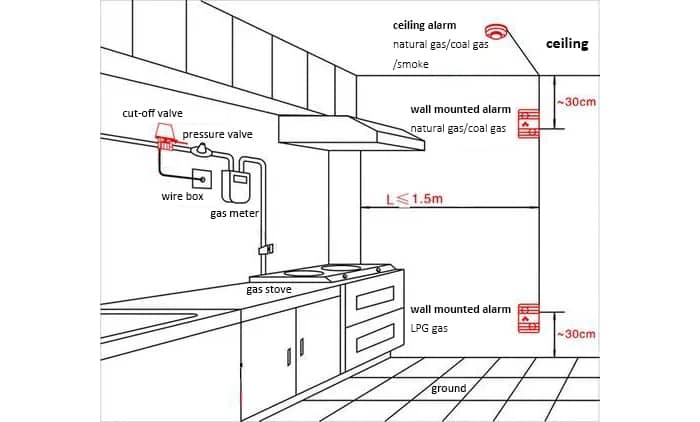

Installation and use of combustible gas alarms

- To detect natural gas and artificial coal gas, the gas alarm should be installed at a distance of 30 to 60 cm from the ceiling;

- When detecting the leakage concentration of liquefied petroleum gas-LPG, the alarm should be installed at a distance of 30-60cm from the ground.

- It’s recommended to install near the gas meter or pipe connection point.

- The alarm should be continuously powered, and cannot be unplugged when going out or falling asleep at night.

As to effectively realize the early warning function, it’s quote important to choose the right gas sensor. As a professional sensor supplier, Winsen now has gas sensors covering the four principles of semiconductor, catalytic combustion, electrochemistry, and infrared absorption, which are widely used in civil, industrial and commercial, and mining combustible gas detection equipment.

Combustible Sensor Selection Guide(click the model for more details)

1)Household gas alarm-can choose semiconductor type for economic cost and long life: MQ-4, MP-4, MC107 and other models;

2)Industrial and commercial gas alarms-can choose catalytic type for high sensitivity and accuracy: MC226A, MC227D and other models;

3)Coal mine gas alarms- explosion-proof, high sensitivity and accuracy:

Catalytic MC11series(MC112/MC113/MC114/MC115/MC119)

Infrared MH series(MH-440D/MH-441D/MH-741A/MH-742B)

Non-complete combustion of natural/LPG/coal gases produce CO gas which is odorless and toxic and called silent killer. It may take lives when reaches certain content in closed space. Winsen has a wide range of CO gas sensors to meet different purpose and demand.

Carbon Monoxide CO Sensor Selection Guide:

1)Household gas alarm-can choose semiconductor type(MOX): MQ-7B,MQ-9B, MP-7, MP-9, which are highly sensitive and long life of above 10 years.

2)Industrial and commercial gas alarms-can choose ME2-CO, MEu-2CO, ME2-CO-Φ14x5, ME2-CO-Ф14x50-C, ME3-CO, ME4-CO

3)Calibrated CO sensor modules ZE07-CO, ZE15-CO, ZE16-CO, ZE18-CO, ZE03-CO...

4)Electronics: GM-702B MEMS

More safety knowledge of combustible gas use:

(1)An alarm should be installed in each operation room to ensure timely detection of gas leakage

(2)Unobstructed ventilation and smoke exhaust should be maintained in the operation room

(3)Gas users must always check whether the two ends of the rubber hose connected to the gas cooker are fixed by clamps; the service life of the rubber hose is 18 months, and it should be replaced in time if it is found to be aging or cracked; it is recommended to use a metal bellows with a longer service life (10 Years)

(4)The rubber hose shall not pass through walls, floors, ceilings, doors, and windows, and the length shall be controlled within 1.2m-2m without joints, and shall not be placed higher than the stove.

(5)Do not use non-compliant gas facilities or those exceed the scrapping period, and the life of the gas stove is 8 years.

(6)Gas tank specifications: users who use liquefied gas tank must have traceable sources, have supplier mark and service line.

(7)The net distance between the steel gas tank and the burner of the stove should be more than 0.5 meters. Generally, the pressure reducing valve is replaced every 3 years.

(8)The tank should be placed upright, and it is strictly forbidden to lie down or expose the tank to the heating source. When not in use, close the valve timely.

(9) Gas users are not allowed to install, dismantle, modify, relocate pipeline gas facilities and measuring instruments without authorization.

(10) It is forbidden to pile up flammable and explosive materials in rooms with gas pipelines or stoves.

(11) It is not allowed to tie or tie ropes, wires and hanging objects on gas facilities.