Understanding Pyroelectric Materials and Sensors: Principles, Applications, and Technology

Pyroelectricity is a fascinating and practical phenomenon found in certain crystalline materials that can generate a temporary voltage when they are heated or cooled. While the concept of pyroelectricity has been known since the 18th century, its commercial and technological significance has grown immensely in the modern era, particularly with the development of pyroelectric sensors. These sensors are widely used in infrared detection, motion sensing, temperature monitoring, and thermal imaging systems.

This article explores the pyroelectric effect, its underlying physical principles, and the applications of pyroelectric materials, with a focus on sensor technologies. Readers will gain a complete understanding of how pyroelectric materials work, where they are used, and what makes them essential in many modern systems.

2. What Is Pyroelectricity?

Pyroelectricity is the ability of certain materials to generate an electrical potential (voltage) in response to a change in temperature. This phenomenon occurs in materials that have a polar crystal structure—meaning they possess a spontaneous electric polarization that changes with temperature.

Unlike thermoelectric materials (which generate continuous voltage with a temperature gradient), pyroelectric materials generate voltage only when there is a change in temperature—that is, during heating or cooling.

Key Points

-

Pyroelectricity is a transient effect: voltage is produced only during temperature changes.

-

It is observed in anisotropic crystals that lack a center of symmetry.

-

Pyroelectric materials are usually also piezoelectric, but not all piezoelectric materials are pyroelectric.

3. The Science Behind Pyroelectricity

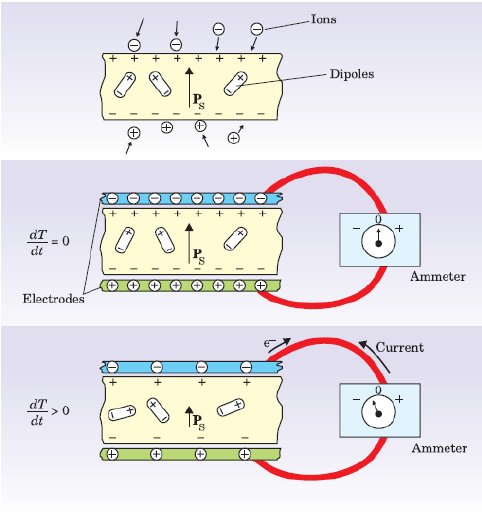

3.1 Crystalline Structure and Polarization

At the atomic level, pyroelectricity arises due to asymmetric charge distribution in certain crystal lattices. These crystals belong to the non-centrosymmetric point groups that allow for spontaneous polarization along a particular axis (typically called the polar axis).

When the temperature changes, the position of atoms shifts slightly, altering the polarization. This shift results in a redistribution of surface charges, which can be detected as an electrical current or voltage.

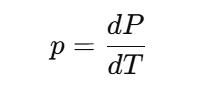

3.2 Pyroelectric Coefficient

The pyroelectric coefficient (p) quantifies the strength of the pyroelectric effect. It is defined as:

Where:

-

p is the pyroelectric coefficient (C/m²·K)

-

P is the polarization (C/m²)

-

T is temperature (K)

A high pyroelectric coefficient indicates that the material can generate a large electrical response to small temperature changes.

4. Common Pyroelectric Materials

Several materials exhibit strong pyroelectric properties. These include:

| Material | Pyroelectric Coefficient (C/m²·K) | Applications |

|---|---|---|

| Triglycine Sulfate (TGS) | ~3 × 10⁻⁸ | Thermal sensors, IR detectors |

| Lithium Tantalate (LiTaO₃) | ~2 × 10⁻⁸ | Laser detection, motion sensors |

| Polyvinylidene fluoride (PVDF) | ~1 × 10⁻¹⁰ | Flexible detectors, wearable tech |

| Barium Titanate (BaTiO₃) | ~1 × 10⁻⁷ | High-sensitivity sensors |

| Gallium Nitride (GaN) | Emerging material | Nanoelectronics, MEMS |

The choice of material depends on desired characteristics such as sensitivity, size, cost, and temperature range.

5. Pyroelectric Sensors: Design and Functionality

Pyroelectric sensors detect infrared (IR) radiation based on the heat it imparts to the sensor material. When IR radiation strikes the sensor, it causes a slight, rapid temperature increase, which generates an electrical signal due to the pyroelectric effect.

5.1 Structure of a Pyroelectric Sensor

A typical pyroelectric sensor consists of:

-

Pyroelectric crystal or film: Converts thermal changes into voltage.

-

Electrodes: Capture the charge generated.

-

Optical filter: Allows only IR wavelengths to reach the sensor.

-

Amplifier and signal processor: Converts weak signals into usable output.

Some sensors use dual-element configurations to reduce false alarms and improve signal discrimination.

6. Applications of Pyroelectric Sensors

6.1 Passive Infrared (PIR) Motion Detectors

One of the most common uses of pyroelectric sensors is in PIR motion detectors. These are used in:

-

Security systems

-

Automatic lighting

-

Smart home automation

They detect human presence based on body heat changes in the environment.

6.2 Infrared Thermometry

Pyroelectric sensors are used in non-contact temperature measurement devices, including:

-

Medical IR thermometers

-

Industrial thermal sensors

-

Fever screening tools (especially during pandemics)

6.3 Flame and Fire Detection

Because flames emit IR radiation, pyroelectric sensors can detect fire or combustion sources quickly and reliably.

6.4 Spectroscopy and Scientific Instruments

High-sensitivity pyroelectric detectors are used in:

-

IR spectroscopy

-

Gas analyzers

-

Laser power meters

These applications often require fast response times and high accuracy.

6.5 Consumer Electronics and Touchless Interfaces

New applications are emerging in:

-

Gesture recognition

-

Thermal-based user interfaces

-

Smartphone temperature sensors

7. Winsen Pyroelectric Sensors

Pyroelectric Flame sensor

Pyroelectric Human Body Induction

8. Advantages and Limitations

8.1 Advantages

-

High sensitivity to IR radiation

-

Fast response time

-

Low power consumption

-

Works in passive mode (no radiation source required)

-

Relatively compact and cost-effective

8.2 Limitations

-

Only responsive to dynamic temperature changes

-

Affected by ambient temperature fluctuations

-

Requires optical filtering and shielding

-

Signal drift and noise can affect long-term reliability

9. Advances in Pyroelectric Materials and Technologies

9.1 Flexible and Organic Pyroelectrics

Materials like PVDF and other polymers allow for flexible, lightweight sensors. These are especially useful in:

-

Wearable devices

-

Biomedical monitoring

-

Flexible robotics

9.2 Nano-structured Materials

Engineered nanostructures, such as pyroelectric nanowires, offer:

-

Enhanced surface area

-

Faster thermal response

-

Integration with MEMS (microelectromechanical systems)

9.3 Multimodal Sensors

Modern designs combine pyroelectric detection with other sensing modalities:

-

PIR + Ultrasonic for advanced motion detection

-

IR + Gas Sensors for environmental monitoring

-

Pyroelectric + AI for smart surveillance

10. Comparison with Related Technologies

| Technology | Pyroelectric | Thermoelectric | Photovoltaic | Bolometer |

|---|---|---|---|---|

| Response | Transient | Continuous | Light-dependent | Thermal resistance change |

| Stimulus | Temperature change | Temperature gradient | Light photons | Temperature increase |

| Output | Voltage (AC) | Voltage (DC) | Current/voltage | Resistance |

| Application | IR sensing, motion | Power generation | Solar cells | Thermal cameras |

Each technology has its niche depending on the nature of the stimulus and the desired output.

11. Environmental and Regulatory Considerations

As pyroelectric sensors are widely used in consumer products, they must meet safety and compliance standards such as:

-

RoHS (Restriction of Hazardous Substances)

-

REACH (European chemical safety regulation)

-

CE/FCC certifications

-

IEC 60730 for safety in automatic electrical controls

12. Future Outlook and Emerging Trends

Pyroelectric materials are seeing a resurgence of interest due to their role in energy harvesting, wearable technology, and IoT devices. Areas of ongoing research include:

-

Self-powered pyroelectric sensors

-

Bio-compatible materials for medical devices

-

Integration with AI and edge computing

-

Pyroelectric nanogenerators for converting waste heat into electricity

Conclusion

Pyroelectricity represents a unique and versatile mechanism that bridges the gap between thermal and electrical phenomena. Pyroelectric sensors have become indispensable in areas ranging from security and automation to healthcare and industrial monitoring. As materials science continues to evolve, these sensors will become more sensitive, compact, and intelligent—driving innovations in both conventional and emerging markets.

Understanding the science, capabilities, and constraints of pyroelectric materials empowers engineers, researchers, and product developers to make informed decisions about sensor technologies and system integration.