Features:

- Multi thread structure, multi output methods

- Wide temperature compensation-10~+70℃

- Excellent anti-interference ability, Low consumption

- High reliability, High Accuracy, Calibrated

It’s very essential to equip intelligent monitor, detectors and sensing device at the vital area of infrastructure of city, transportation, drainage, etc. Data of water level and pressure can be collected and monitored in real time through online system. In normal conditions, the device are helpful for infrastructure management, and when there is floods risks, early watching and warning can be realized to leave time for flood control dispatch and emergency rescue.

In flood season and strong convective weather, how to detect water level on the road at the first time and take timely measures will always test the drainage scheduling and operation ability of urban drainage management system.

The urban water level monitoring and early warning system involves monitoring of urban rainfall, river and lake water regime, pumping station operation, road and bridge ponding, and drainage equipment operation, etc. With highly integrated equipment, pressure sensors are mainly used in areas such as overpasses, bridges, roads, streets, and tunnels to monitor the water level in real time.

The most direct use of the pressure sensor is to measure the gas, liquid pressure, by using the relationship between the liquid pressure and the liquid height, and the pressure sensor can be used to measure the liquid level.

The pressure P of a liquid is determined by the relationship: p =ρgh. For the same kind of liquid, the liquid density ρ is constant, therefore, the pressure P of the liquid is proportional to the height h of the liquid surface (height from the liquid surface). It is not difficult to find that the pressure of the liquid changes at different levels.

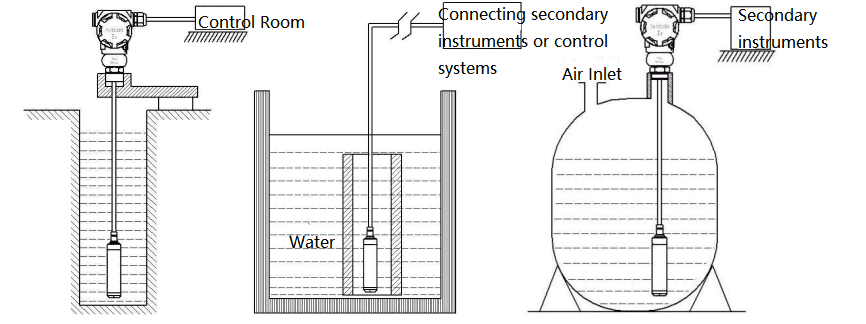

Installation Figure of pressure transmitter in liquid level detection

Installation Figure of pressure transmitter in liquid level detection

| WPCK81 Level Transmitter | |

|---|---|

| Detection principle: | Piezoresistive |

| Output signal: | 4-20mA; RS485 |

| Resolution and accuracy: | ±0.5%FS(Range>1m); ±1%FS(Range=1m) |

| Response time: | ≤1ms |

| Pressure Range: | 0~1m…5m…200mH₂O |

| Working Temperature: | -20℃~85℃ |

| Diaphragm material: | SS 316L |

| Protection class: | IP68 |

a.When measuring the static fluid level in an open container, place the level transmitter vertically at the bottom of the container, and fix the cable and junction box connecting the transmitter at the opening of the container.

b.When the medium viscosity is high (such as in a sewage tank), a sleeve or bracket can be installed to ensure that the transmitter can be inserted into the bottom of the container.

a.When measuring the water level in flowing water, when the medium fluctuates greatly, a steel pipe with an inner diameter of ≥ 5 centimeters can be inserted into the waterway. Several pipes can be opened at different heights in the opposite direction of the water flow when the pipe invading the water is located Φ A small hole around 5 allows water to enter the pipe and fix the cable and junction box at the outlet of the pipe.

b.When the water channel medium fluctuates and sediment is large, damping devices can also be installed to filter sediment and eliminate the adverse effects of dynamic pressure and waves, ensuring measurement accuracy.

| WPCK03 Diffused Silicon Pressure Transmitter | |

|---|---|

| Detection principle: | Diffused Silicon |

| Output signal: | I2C(Pressure/Temperature), 4-20mA, 0.5-4.5V and others |

| Resolution and accuracy: | ±0.2%FS, ±0.5%FS |

| Response time: | ≤1ms |

| Pressure Range: | -100kPa~0~10kPa…100MPa |

| Pressure Reference: | Gauge Pressure/Absolute Pressure/Sealed Gauge Pressure |

| Working Temperature: | -40~80℃ |

| Diaphragm material: | SS 316L |

| WPAK63 Isolation-Film Pressure Sensor | |

|---|---|

| Detection principle: | Diffused Silicon |

| Response time: | ≤1ms |

| Pressure Range: | -100kPa~0~10kPa…100MPa |

| Pressure Reference: | Gauge Pressure/Absolute Pressure/Sealed Gauge Pressure |

| Working Temperature: | -40℃~120℃ |

| Diaphragm material: | SS 316L |