Photoconductive Sensors: Principles, Materials, Applications, and Advances

1. Introduction

Photoconductive sensors are a class of light sensors that operate based on the photoconductive effect, wherein the electrical conductivity of a material changes when it is exposed to light. These sensors are widely used in various fields including consumer electronics, industrial automation, astronomy, optical communication, and safety systems.

This article provides a detailed overview of photoconductive sensors, exploring their working principle, materials used, types, applications, benefits, limitations, and current research trends.

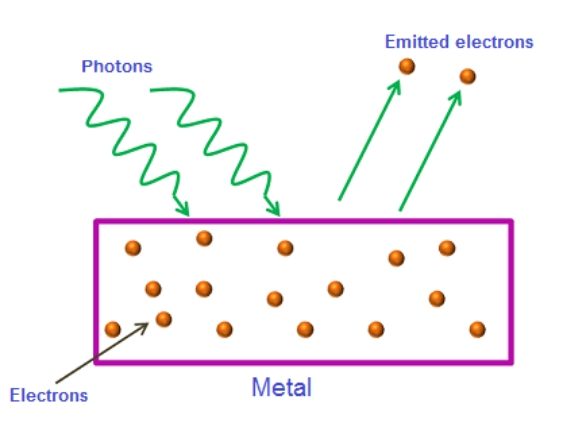

2. What is the Photoconductive Effect?

The photoconductive effect refers to the increase in the electrical conductivity of a material when it is exposed to electromagnetic radiation, especially in the visible or infrared spectrum. When photons strike the surface of a photoconductive material, they excite electrons from the valence band to the conduction band, resulting in free charge carriers (electrons and holes) that increase the material's conductivity.

2.1 Basic Concept

- In the dark, photoconductive materials behave like insulators or semiconductors.

- When illuminated, their resistance decreases, allowing more current to flow through the material.

2.2 Governing Equation

Ohm’s Law still applies:

I=V/R

Where R is variable and decreases with increasing light intensity.

3. Photoconductive Materials

Photoconductive sensors rely on semiconducting materials that show significant changes in conductivity when exposed to light.

3.1 Common Photoconductive Materials

- Cadmium Sulfide (CdS) – Visible spectrum, widely used in photoresistors.

- Cadmium Selenide (CdSe) – Extended spectral response.

- Lead Sulfide (PbS) – Infrared detection.

- Germanium (Ge) – Used in infrared sensors.

- Silicon (Si) – Used in integrated photodetectors.

- Amorphous Silicon (a-Si) – Thin-film devices.

- Gallium Arsenide (GaAs) – High-speed applications.

- Organic semiconductors – Flexible and printable photodetectors.

3.2 Material Properties to Consider

- Bandgap energy

- Response time

- Stability under light exposure

- Environmental durability

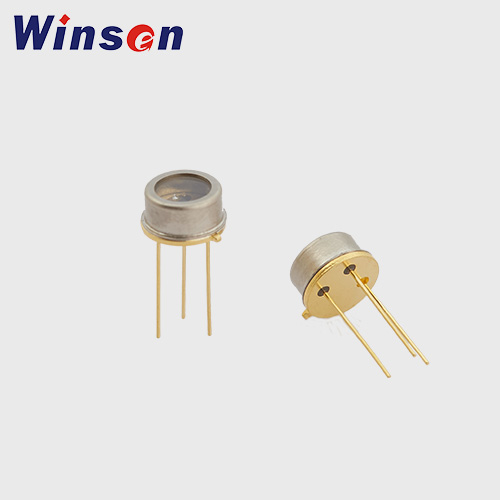

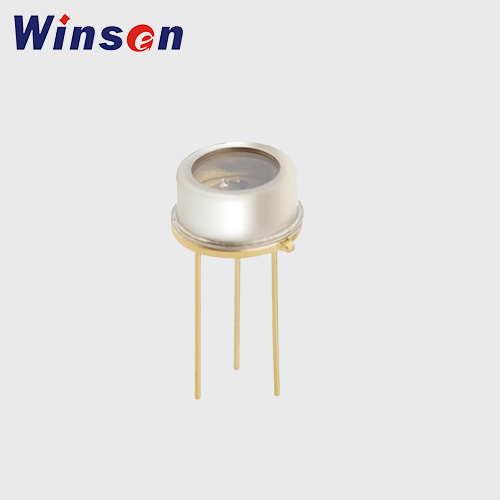

4. Photoconductive Devices: Photoresistors

The most common photoconductive devices are photoresistors, also known as light-dependent resistors (LDRs).

4.1 Construction

Typically composed of CdS or CdSe, with a serpentine conductive path that maximizes surface area for light exposure.

4.2 Working Principle

- In darkness, the resistance is high (in MΩ range).

- When exposed to light, resistance drops drastically, enabling current to pass more freely.

4.3 Resistance vs. Light Intensity

R ∝ 1/L

Where L is the light intensity.

5. Circuit Integration

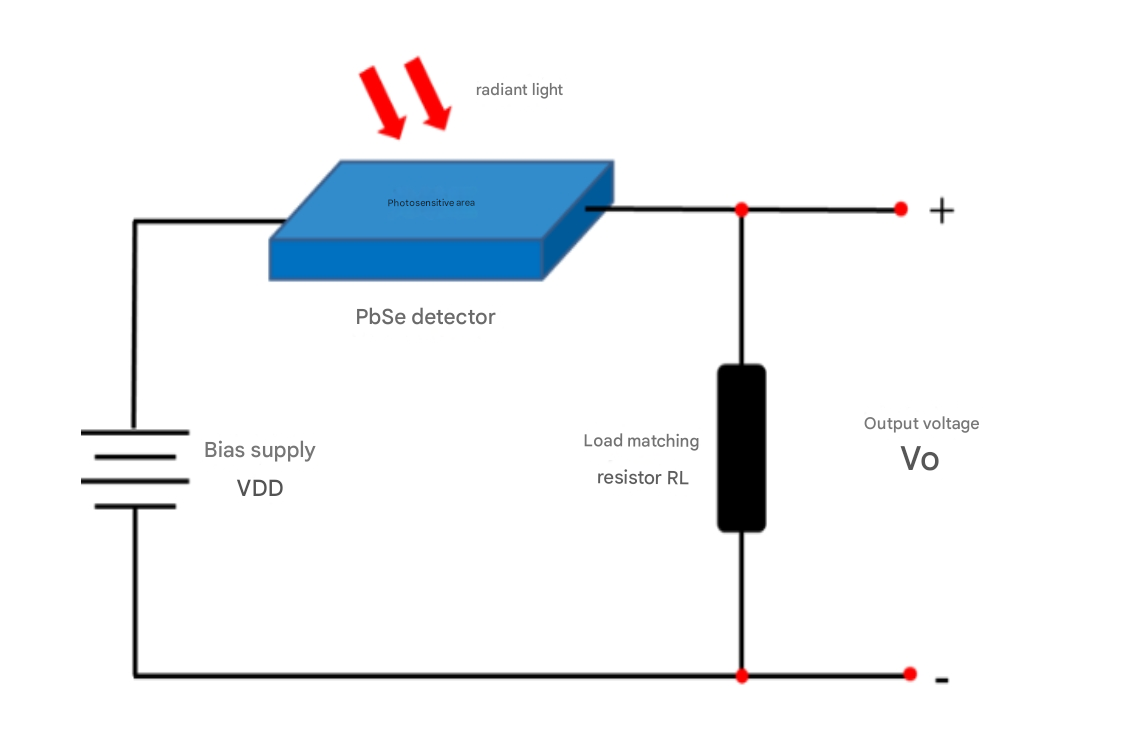

Photoconductive sensors are typically integrated into circuits as voltage dividers or analog inputs to microcontrollers.

5.1 Simple Voltage Divider

Vout = Vcc * (R2 / (R1 + R2))Where R1 is a fixed resistor and R2 is the LDR. The voltage output changes based on light levels.

5.2 Signal Conditioning

- Analog-to-digital conversion (ADC)

- Amplification for weak signals

- Filtering to reduce noise

6. Types of Photoconductive Sensors

Photoconductive sensors can be categorized based on material, spectral response, and application.

6.1 Based on Spectral Range

- Visible Light Sensors – CdS, CdSe.

- Infrared Sensors – PbS, InSb, Ge.

6.2 Based on Application

- Ambient light sensors

- Flame detectors

- Solar tracking systems

- Optical encoders

- Position sensors

6.3 Winsen Photoconductive Sensors

7. Applications of Photoconductive Sensors

7.1 Consumer Electronics

- Automatic brightness adjustment in smartphones and TVs

- Night mode triggering in cameras

- Gesture recognition using light-based sensors

7.2 Industrial Automation

- Object detection on conveyors

- Position and alignment sensors

- Speed measurement in rotating systems

7.3 Security and Surveillance

- Light barriers and beam-break detectors

- Flame and heat detection systems

- Intrusion alarms triggered by light interruption

7.4 Astronomy and Research

- Photometry for stellar brightness measurement

- Infrared telescopes with PbS sensors

7.5 Automotive

- Ambient light sensing for dashboard brightness

- Rain/light sensors for automated wipers and headlamps

8. Advantages of Photoconductive Sensors

- Simple Design – Few components, easy to integrate

- Low Cost – Especially CdS-based LDRs

- Wide Dynamic Range – Can detect both low and high light levels

- Analog Output – Offers granularity in light measurement

- Passive Operation – No internal power required for sensing mechanism

9. Limitations

Despite their usefulness, photoconductive sensors have certain drawbacks:

- Slow Response Time – Particularly CdS-based sensors (10–100 ms)

- Temperature Sensitivity – Resistance can drift with temperature

- Toxicity – Some materials like CdS and PbS are environmentally hazardous

- Spectral Limitations – Each material is limited to specific wavelengths

- Non-linear Response – Not ideal for precision light measurement

10. Comparison with Other Optical Sensors

| Feature | Photoconductive Sensor | Photodiode | Photovoltaic Sensor |

|---|---|---|---|

| Output Type | Resistance change | Current/voltage | Voltage |

| Response Time | Slow (ms) | Fast (μs–ns) | Medium (μs) |

| Sensitivity | Medium | High | Medium |

| Cost | Low | Moderate | Low |

| Linearity | Poor | Excellent | Good |

| Best Use | Ambient light, hobby | Precision detection | Solar cells |

11. Innovations and Recent Developments

11.1 Organic Photoconductors

- Flexible, printable sensors

- Lower toxicity

- Used in wearable devices and flexible electronics

11.2 Nanostructured Materials

- ZnO nanorods, graphene-based films

- Improved response speed and sensitivity

- Enables UV and deep IR detection

11.3 CMOS-Compatible Sensors

- Integration into microelectronics

- Used in digital imaging and biomedical sensing

11.4 Smart Sensor Integration

- Built-in ADC and microcontroller

- IoT-ready photoconductive sensors

- Remote monitoring via wireless communication

12. Safety and Environmental Considerations

Certain photoconductive materials contain toxic elements such as cadmium or lead. When designing systems, engineers must:

- Comply with RoHS (Restriction of Hazardous Substances) regulations

- Ensure proper disposal and recycling

- Explore eco-friendly alternatives like ZnO or organic semiconductors

13. How to Choose the Right Photoconductive Sensor

Factors to Consider:

- Spectral Response Range – Match sensor to light source.

- Response Time – Fast or slow applications.

- Operating Environment – Temperature, humidity, exposure.

- Form Factor – Through-hole, SMD, flexible film.

- Budget and Availability – Cost vs. performance trade-offs.

14. Conclusion

Photoconductive sensors offer a straightforward and cost-effective way to detect light and convert it into an electrical signal. Their simple construction, reliability, and adaptability have made them staples in both legacy and modern systems. Although more sophisticated alternatives like photodiodes and phototransistors are gaining ground, photoconductive sensors continue to play an important role in many low-cost, analog, or ambient light applications.

With continued research into materials science and nanoengineering, we can expect next-generation photoconductive sensors to deliver faster responses, higher sensitivity, and greener manufacturing processes.