What is a refrigerant?

A refrigerant is a chemical substance used in refrigeration and air conditioning systems. They work by absorbing heat and transferring it in a cycle to achieve cooling of air or objects.

Refrigerants typically have low boiling points, allowing them to evaporate and cool the surrounding environment at relatively low temperatures. When in liquid state, the refrigerant absorbs heat and evaporates into a gas. Then, through compression and condensation processes, the refrigerant releases heat and returns to a liquid state, preparing for the next cycle.

What are the types and codes of commonly used refrigerants?

Chlorofluorocarbons (CFCs)

- R11 (trichlorofluoromethane)

- R12 (dichlorodifluoromethane)

- R113 (trichlorotrifluoroethane)

- R114 (dichlorotetrafluoroethane)

- R115 (chloropentafluoroethane)

Hydrochlorofluorocarbons (HCFCs)

- R22 (chlorodifluoromethane)

- R123 (1,1,1-trichloro-2,2,2-trifluoroethane)

- R124 (dichlorofluoroethane)

Hydrofluorocarbons (HFCs)

- R134a (1,1,1,2-tetrafluoroethane)

- R410A (50% R32 + 50% R125)

- R404A (44% R125 + 52% R143a + 4% R134a)

- R407C (23% R32 + 25% R125 + 52% R134a)

Hydrofluoroolefins (HFOs)

- R1234yf (2,3,3,3-tetrafluoropropene)

- R1234ze(E) (2,3,3,3-tetrafluoropropene)

In the past decades, chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs) were widely used as refrigerants. However, due to their detrimental impact on the ozone layer and contribution to global warming, international actions have been taken to restrict and phase out these substances. Modern refrigerants typically belong to the hydrofluorocarbons (HFCs) or hydrofluoroolefins (HFOs) category, which have reduced ozone depletion potential.

What is a good refrigerant?

An ideal refrigerant should have the following physical and chemical properties

Physical Characteristics

- High Evaporative Pressure: The refrigerant should have a higher evaporative pressure than atmospheric pressure to prevent air from entering the system, making system handling easier.

- High Latent Heat of Evaporation: A refrigerant with a high latent heat of evaporation can absorb a large amount of heat with a smaller quantity of refrigerant.

- High Critical Temperature: A higher critical temperature indicates that the refrigerant can be condensed and liquefied using ambient air or water at normal temperatures.

- Low Condensing Pressure: A low condensing pressure allows the refrigerant to be liquefied at lower pressures, reducing the compression ratio and saving compressor power.

- Low Freezing Temperature: The refrigerant should have a low freezing point to prevent it from freezing and causing circulation issues within the evaporator.

- Low Specific Volume of Gaseous Refrigerant: A lower specific volume of the gaseous refrigerant is desirable as it allows for smaller compressor volumes, reducing costs, and enabling the use of smaller refrigerant piping for suction and discharge.

- High Density of Liquid Refrigerant: A higher density of the liquid refrigerant enables the use of smaller liquid lines for piping.

- Solubility in Refrigeration Oil: The refrigerant should be soluble in refrigeration oil to eliminate the need for oil separators in the system.

Chemical Characteristics

- Chemical Stability: The refrigerant should exhibit stable chemical properties and not undergo chemical decomposition or other changes during its application temperature range.

- Non-corrosiveness: The refrigerant should not corrode steel or other metals. For example, ammonia is corrosive to copper, so copper pipes should not be used in ammonia refrigeration systems. Good insulation properties are also required to prevent damage to the compressor motor insulation, ensuring no direct contact with copper coils.

- Non-environmental Pollutant: The refrigerant should be environmentally friendly, causing no harm to the natural environment, and should have a low impact on the ozone layer and a low greenhouse effect.

- Non-toxic: The refrigerant should be non-toxic, posing no health hazards to humans.

- Non-explosive and Non-combustible: Ideal refrigerants should not be explosive or flammable to ensure system safety.

So, a good refrigerant should possess high efficiency, environmental friendliness, safety, compatibility and substitutability, and economic feasibility. These characteristics contribute to sustainable refrigeration and air conditioning systems, reducing their negative impact on the environment, while ensuring comfort and safety for individuals.

High efficiency: A good refrigerant should have high cooling capacity and heat transfer efficiency to achieve quick and effective refrigeration. It should be able to deliver the desired cooling effect under given operating conditions while minimizing energy consumption and operational costs.

Environmental friendliness: Excellent refrigerants should have minimal impact on the atmospheric ozone layer and global warming. They should have low or zero ozone depletion potential (ODP) and low global warming potential (GWP). This helps to reduce damage to the ozone layer and mitigate adverse effects on the Earth's climate.

Safety: Refrigerants should have good safety performance, including low toxicity and low flammability. They should be stable and reliable under normal operating conditions, without posing harm to human health and the environment.

Compatibility and substitutability: Good refrigerants should be compatible with existing refrigeration equipment and systems, and serve as substitutes for current refrigerants. This helps to minimize the cost of equipment replacement and system retrofitting, while facilitating the adoption of sustainable and environmentally friendly measures.

Economic feasibility: The cost of refrigerants should be reasonable and affordable to ensure their economic viability in commercial and industrial applications. Economic feasibility is an important consideration when evaluating the goodness of a refrigerant.

Refrigerants commonly used in air conditioners

R410A: This is a non-ozone-depleting blend refrigerant composed of R32 and R125. It is widely used in residential and commercial air conditioning systems, offering high efficiency and low global warming potential.

R32: Also known as difluoromethane, it is a single-component refrigerant. It exhibits high evaporating pressure and latent heat, making it suitable for high-efficiency performance in air conditioning systems. R32 is also widely used in residential and commercial air conditioning equipment.

R22: Also referred to as chlorodifluoromethane or Freon-22, it is a refrigerant that has been phased out due to its harmful impact on the ozone layer. It used to be commonly used in air conditioning systems but is now considered environmentally harmful.

R134a: Also known as tetrafluoroethane or Freon-134a, it is a common alternative refrigerant used in automotive air conditioning and household refrigeration equipment. It has a lower ozone depletion potential compared to R22 but still contributes to greenhouse gas emissions.

It is important to note that, due to environmental and sustainability concerns, some countries and regions are gradually phasing out the use of refrigerants with significant environmental impacts, such as R22, and transitioning to more environmentally friendly alternatives like R410A and R32.

| Refrigerant |

Advantages |

Disadvantages |

Global-Warming Potential (GWP)*1 |

Toxicity & Flammability Class |

| R410A |

Non-ozone-depleting |

High global warming potential |

2090 |

A1 |

| High energy efficiency |

| Widely available and used in various systems |

| R32 |

Single-component,higher efficiency |

Mild flammability |

675 |

A2L |

| Lower global warming potential |

| Becoming more commonly used in newer systems |

| R22 |

Widely used in older systems |

ozone-depleting potential |

1810 |

A1 |

| Good thermodynamic properties |

| R134a |

Non-ozone-depleting |

High global warming potential |

1430 |

A1 |

| Good thermodynamic properties |

| Widely used in automotive and household systems |

Performance comparison between R32 and R410A

Environmental Impact

R32 has a lower Global Warming Potential (GWP) of 675, which means it has a lower greenhouse effect compared to other refrigerants.

R410A has a higher GWP of approximately 2088, contributing more to greenhouse gas emissions.

Thermal Efficiency

R32 has higher condensing and evaporating temperatures, resulting in higher energy efficiency in air conditioning systems.

R410A performs slightly lower than R32 and requires larger condensers and evaporators to achieve the same cooling effect.

Safety

R32 is mildly flammable and falls into the A2L classification (mildly flammable, low toxicity) of refrigerants. Special safety measures are required during handling and usage.

R410A is a non-flammable refrigerant and falls into the A1 classification (non-flammable, non-toxic), making it relatively safer.

System Design

R32 refrigerant systems can be designed with smaller components due to its higher condensing and evaporating temperatures, resulting in reduced system mass.

R410A refrigerant systems require larger components to accommodate its higher condensing and evaporating temperatures.

How to detect refrigerant leaks

Visual, Olfactory, and Auditory Inspection: Observing for visible refrigerant leaks, smelling for unusual odors (such as a pungent smell), and listening for abnormal sounds (like hissing noises indicating a gas leak).

Gas Detection Agents: Using specialized gas detection agents, spraying them on suspected areas of leakage, such as pipe connections and valves. If there is a leak, the gas detection agent will produce bubbles or a color change, indicating the location of the leak.

UV Detection: By adding a special ultraviolet (UV) tracer dye to the refrigerant and using a UV lamp to illuminate potential leak areas. If there is a leak, the tracer dye will emit visible fluorescence, aiding in leak detection and localization.

Electronic Leak Detectors: These are dedicated electronic devices designed to detect refrigerant leaks. They utilize refrigerant leak sensors to detect changes in refrigerant concentration in the air and provide an alert or indication when a leak is detected.

What are the commonly used refrigerant detector sensors?

Infrared refrigerant gas sensor

Working Principle

Infrared sensors detect the presence and concentration changes of refrigerant by measuring the absorption characteristics of refrigerant molecules in the infrared spectrum.

Advantages:

- High Sensitivity: Infrared sensors are highly sensitive to the absorption characteristics of refrigerants and can detect low concentrations of refrigerants.

- High Selectivity: Infrared sensors can achieve selective detection of specific refrigerants by adjusting the wavelength range of detection.

- Long Lifespan: Infrared sensors typically have a long lifespan and high stability.

Disadvantages:

- Higher Cost: Infrared sensors are relatively more expensive compared to other sensor types.

- Environmental Impact: Infrared sensors are sensitive to environmental conditions such as temperature and humidity and need to be used in appropriate environments.

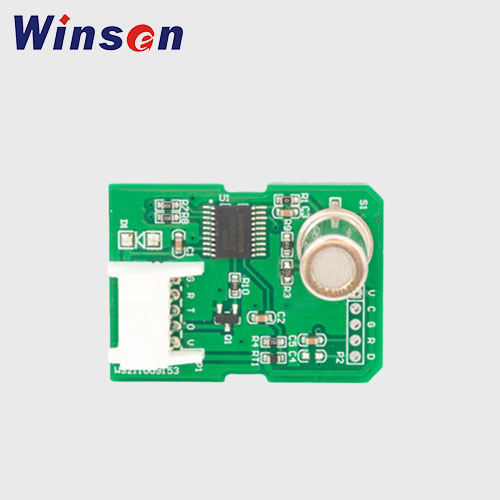

Semiconductor refrigerant gas sensor:

Working Principle

Semiconductor sensors utilize the interaction between refrigerants and semiconductor materials to detect the presence and concentration changes of refrigerants by measuring variations in resistance, capacitance, or current.

Advantages:

- Low Cost: Semiconductor sensors usually have a lower cost and are suitable for large-scale applications.

- Miniaturization: Semiconductor sensors have a small size and can be easily integrated into various devices and systems.

- Real-Time Response: Semiconductor sensors have a fast response time, enabling real-time monitoring of refrigerant leaks.

Disadvantages:

- Poor Selectivity: Semiconductor sensors are sensitive to multiple gases and may be affected by interference from other gases.

- Limited Sensitivity: Semiconductor sensors have relatively lower sensitivity to refrigerants and may not detect low-concentration leaks.