Refrigerants in heat pumps

Heat pumps are an energy-efficient and eco-friendly alternative for heating and cooling systems. Central to their operation is the use of refrigerants, which play a crucial role in the heat transfer process. In this article, we will explore what refrigerants are, their properties, the types commonly used in heat pumps, and their impact on the environment. We will also discuss the issue of refrigerant leaks and its implications.

What exactly is refrigerant?

Refrigerant is a specialized fluid or gas used in heat pumps and other cooling systems to facilitate heat transfer. It undergoes a continuous cycle of evaporation and condensation, absorbing heat from one location and releasing it in another. The refrigerant's ability to change states at relatively low temperatures makes it an ideal medium for heat transfer.

More about refrigerant: https://www.winsen-sensor.com/knowledge/what-is-a-refrigerant.html

Refrigerant properties

Refrigerants possess specific properties that make them suitable for heat pump applications. They have low boiling points, allowing them to evaporate at low temperatures and absorb heat from the surrounding environment. They also have high latent heat capacities, meaning they can absorb and release a significant amount of heat during phase changes. Additionally, refrigerants must have good thermal stability, compatibility with system materials, and low toxicity levels.

What refrigerants are used in heat pumps?

Different refrigerants have been used in heat pumps over the years, with advancements driven by environmental concerns and regulations. Common refrigerants include hydrochlorofluorocarbons (HCFCs), hydrofluorocarbons (HFCs), and natural refrigerants such as ammonia (NH3), carbon dioxide (CO2), and hydrocarbons (HCs). Each refrigerant has its own advantages and disadvantages in terms of performance, efficiency, safety, and environmental impact.

| Code | Category | Global Warming Potential | Comment |

| R-410a | HFC | Very High | Avoid |

| R-134a | HFC | Very High | Avoid |

| R-34 | HFC | High | Meh |

| R-1234yf | HFO | Low | Choose |

| R-290 | HC | Low | Choose |

| R-744 | CO2 | Low | Choose |

The best refrigerant for Heat Pump systems

The best refrigerant for heat pump must be non-corrosive, non-toxic, non-flammable, with no ozone depletion and global warming potential, as well as easy to produce.

Determining the best refrigerant for a heat pump system depends on various factors, including efficiency, environmental impact, safety, and regulatory compliance. Natural refrigerants like CO2 and ammonia are gaining popularity due to their low global warming potential (GWP) and ozone depletion potential (ODP). They are considered environmentally friendly alternatives to synthetic refrigerants like HFCs, which have high GWPs.

How Do Heat Pump Refrigerants Affect the Environment?

Global Warming Potential (GWP): GWP measures the potential of a refrigerant to contribute to global warming over a specific timeframe, usually 100 years. Refrigerants with high GWP, such as hydrofluorocarbons (HFCs), can significantly contribute to climate change if released into the atmosphere. These HFCs have GWPs that can be thousands of times higher than carbon dioxide (CO2), which is a major greenhouse gas. The long-term accumulation of HFCs in the atmosphere can trap heat, leading to global warming and its associated impacts.

Ozone Depletion Potential (ODP): ODP measures the potential of a refrigerant to deplete the ozone layer. Certain refrigerants, such as chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs), have high ODP and have been phased out due to their harmful effects on the ozone layer. Ozone depletion can have severe consequences, including increased exposure to harmful ultraviolet (UV) radiation from the sun.

Flammable and explosive:Some refrigerants, particularly hydrocarbons (HCs) like propane (R290) and butane (R600), have a chemical structure that makes them highly flammable. These refrigerants consist of carbon and hydrogen atoms, which can easily combust when exposed to an ignition source.leaks can result in fires or explosions and the release of harmful substances into the environment.

Transition to Low-GWP Refrigerants: The industry is transitioning to low-GWP refrigerants, including natural refrigerants such as carbon dioxide (CO2), ammonia (NH3), and hydrocarbons (HCs). These refrigerants have significantly lower GWPs compared to HFCs, making them more environmentally friendly alternatives. They also have minimal or no ozone depletion potential, reducing their impact on the ozone layer.

It is crucial to prevent and promptly repair leaks to minimize environmental impact. Regular maintenance and proper handling of refrigerants are essential to ensure their containment within heat pump systems.

Using sensors to detect refrigerant leaks

Infrared refrigerant gas sensor

Working PrincipleInfrared sensors detect the presence and concentration changes of refrigerant by measuring the absorption characteristics of refrigerant molecules in the infrared spectrum.

Advantages:- High Sensitivity: Infrared sensors are highly sensitive to the absorption characteristics of refrigerants and can detect low concentrations of refrigerants.

- High Selectivity: Infrared sensors can achieve selective detection of specific refrigerants by adjusting the wavelength range of detection.

- Long Lifespan: Infrared sensors typically have a long lifespan and high stability.

- Higher Cost: Infrared sensors are relatively more expensive compared to other sensor types.

- Environmental Impact: Infrared sensors are sensitive to environmental conditions such as temperature and humidity and need to be used in appropriate environments.

MH-Z1542B-R32 Freon Refrigerant Sensor Module

- Refrigerant

- 0~5.00% Vol

- Read More

MH-441D NDIR Infrared Refrigerant Sensor

- Refrigerant

- 0~5%VOL

- Read More

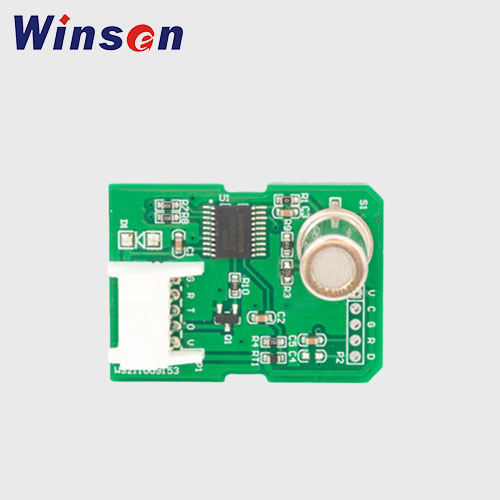

Semiconductor refrigerant gas sensor:

Working PrincipleSemiconductor sensors utilize the interaction between refrigerants and semiconductor materials to detect the presence and concentration changes of refrigerants by measuring variations in resistance, capacitance, or current.

Advantages:- Low Cost: Semiconductor sensors usually have a lower cost and are suitable for large-scale applications.

- Miniaturization: Semiconductor sensors have a small size and can be easily integrated into various devices and systems.

- Real-Time Response: Semiconductor sensors have a fast response time, enabling real-time monitoring of refrigerant leaks.

- Poor Selectivity: Semiconductor sensors are sensitive to multiple gases and may be affected by interference from other gases.

- Limited Sensitivity: Semiconductor sensors have relatively lower sensitivity to refrigerants and may not detect low-concentration leaks.

ZP211 Refrigerant gas detection module

- Refrigerant gas R290

- Read More

ZP201 r32 gas sensor module

- Refrigerant gas R32

- Alarm value 5000ppm

- Read More

MP510C r134a sensor

- refrigerant gases:R32、R134a、R410a、R290

- 100-10000ppm

- Read More