| Target: | C3H8、smoke |

| Model: | ZP13 |

| Detection range: | Output A signal switching value output |

| Detection principle: | Module,semiconductor |

| Characteristics: | High sensitivity,excellent long term stability, calibrated before shipment 10 seconds to 5 minutes with auto-preheating function Faulty auto-check |

| Size: | 24.1×20.1×15.6 |

| Working conditions: |

Working voltage 5±0.2V Ourput TTL level Response time≤20s |

| Notes: | Output signal A (high level generates an alarm signal, and low level does not generate an alarm signal) |

ZP13 Manual download

Get Price Whatsapp

Description

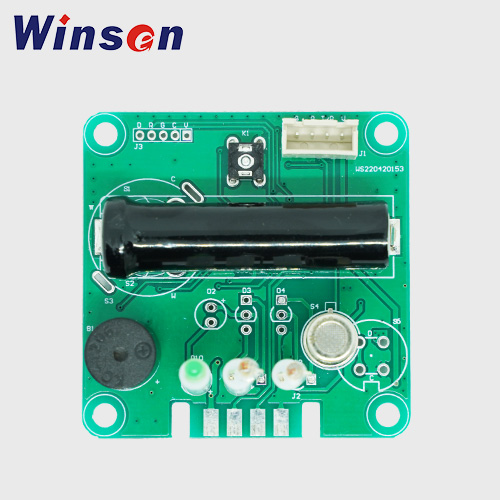

ZP13 adopts advanced plat surfaced semiconductor sensor. It is highly sensitive to smoke, propane &etc gases. The module is calibrated and has good uniformity and highly sensitivity.

Application

Widely used in smoke alarm for home use, smoke alarm for industrial use and portable smoke detector

Features

Highly sensitivity, good long-term stability, calibrated, 3min preheating judgement, fault self-diagnosis, low power consumption, long lifespan, high cost-effective.

Specifications

| Model No. | ZP13 |

| Detection gas | Propane, smoke |

| Physical Interface | XH2.54-4P terminal socket |

| Output Data | A signal on-off output |

| Working voltage | 5.0±0.2V DC(No voltage reverse protection) |

| Output data type | TTL level(200Ω protected resistance inside) |

| Working current | ≤60mA |

| Warm up time | ≤3 min |

| Response Time | ≤20 s |

| Recovery Time | ≤60 s |

| Operating Temperature | 0~50℃ |

| Operating Humidity | ≤95%RH |

| Storage Temperature | -20~60℃ |

| Storage Humidity | ≤60%RH |

| Size | 24×20×15mm(L×W×H) |

| Weight | ≤20g |

| Sensitivity Attenuator | ≤1%/ year |

| Life Span | ≥5 years |

* The description and specifications might be changed without notice. Please contact us for the latest information before placing orders.

Technical Support:

Customized technical design and function, LOGO and package are available without extra charge (including molding fee) for mass volume.

The sensors don't have sleeping mode. It can be set in program if needed.

All Winsen products go through strict inspections and tests to make sure they are 100% qualified before shipping out.

The sensor has been fully tested (not calibrated) before leaving the factory, but the module will be calibrated before leaving the factory.

However, after transportation and storage, the environment conditions change, and the surface of the sensor absorbs moisture, mixed gas, pollution matters, etc. It is recommended that customers perform aging and calibration after sensors become stable according to the program and use occasions of the whole device.

15﹪-90﹪RH without condensation,greater or less than this range or long-term high temperature and high humidity will affect the life of the sensor.

Our sensors are certified with CE, 3C, ROHS, anti-explosion, fire prevention, and coal mining safety according to different applications. And we provide assistance for new certification.

Many factors can cause the sensor to fail such as broken wires in transportation, poisoning, falling off of the sensitive material, damage to the heating wire (device), etc. Please find specific cause in each category with Winsen’s aftersales.

Winsen provides professional consultation and service before and after sales. We will recommend the best fitting sensor for your demand. If you have any problem, don’t hesitate to email us to sales@winsensor.com

Due to high volume of daily incoming emails and time zone difference, we may not be able to reply your emails immediately. But we will reply to your inquiry in 24 business hours.