NDIR Sensor (Non-Dispersive Infrared): Principle, Design, Applications, and Advantages

1. Introduction to NDIR Sensors

NDIR, or Non-Dispersive Infrared, refers to a type of gas sensor technology that detects specific gases by measuring their absorption of infrared (IR) light at characteristic wavelengths. It is widely used for detecting gases such as CO₂, CH₄, CO, refrigerants, hydrocarbons, and other IR-active gases.

NDIR sensors are valued for their accuracy, stability, long lifespan, and low maintenance requirements, making them ideal for critical applications in indoor air quality, industrial safety, environmental monitoring, and HVAC systems.

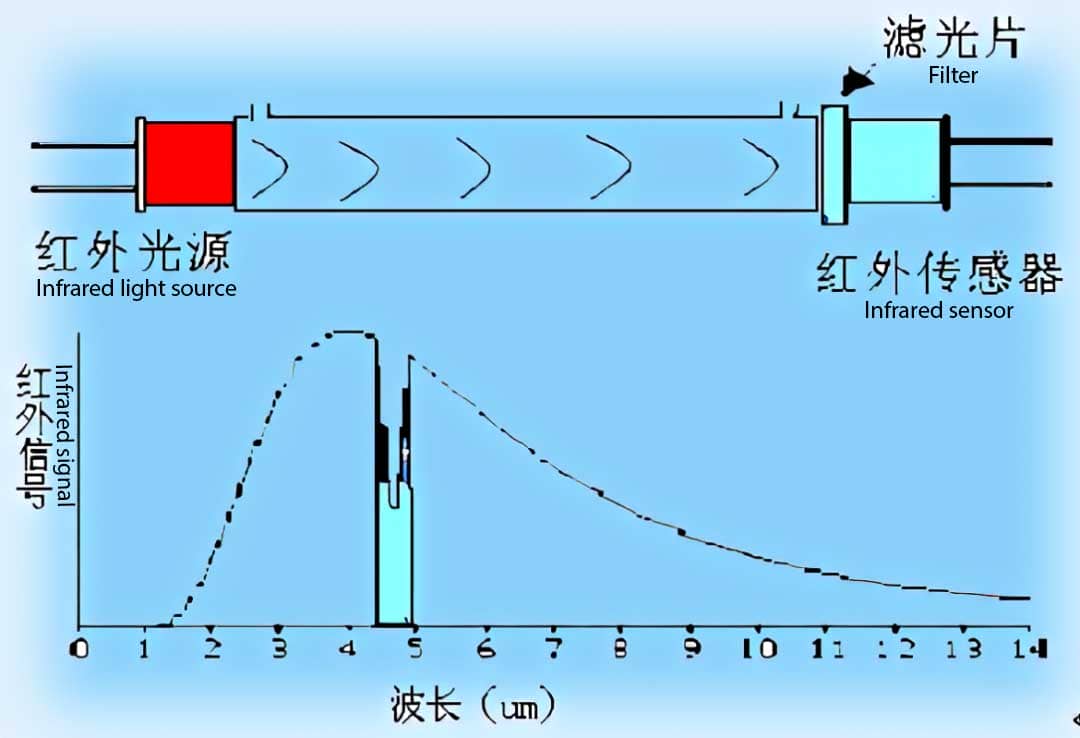

2. Working Principle of NDIR Sensors

NDIR sensors operate based on infrared absorption spectroscopy. Most gases absorb infrared light at specific wavelengths unique to their molecular structure. By measuring the amount of IR light absorbed, the concentration of a target gas can be determined.

2.1 Components of an NDIR Sensor

-

Infrared Light Source

- Usually a thermal emitter (e.g., tungsten filament) that emits a broad spectrum of infrared light.

-

Optical Path (Sample Chamber)

- The gas to be measured flows through a chamber where the IR light passes through it.

-

Optical Filter

- Filters the IR light to a specific wavelength absorbed by the target gas (e.g., 4.26 µm for CO₂).

-

Infrared Detector

- Measures the intensity of IR light that reaches it after passing through the gas.

-

Reference Channel (optional)

- Detects IR light at a wavelength not absorbed by any gas to act as a baseline.

-

Signal Processor

- Converts the light absorption into a digital signal representing gas concentration.

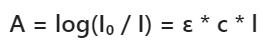

2.2 Beer-Lambert Law

The measurement principle is mathematically described by the Beer-Lambert Law:

Where:

- A = Absorbance

- I₀ = Intensity of light entering the gas

- I = Intensity of light exiting the gas

- ε = Molar absorptivity (a constant for each gas and wavelength)

- c = Concentration of the gas

- l = Path length of the light through the gas

3. Gases Detectable by NDIR Sensors

NDIR sensors are effective for detecting gases with infrared absorption bands, such as:

| Gas | Typical IR Absorption Wavelength (µm) |

|---|---|

| CO₂ (Carbon Dioxide) | 4.26 |

| CO (Carbon Monoxide) | 4.67 |

| CH₄ (Methane) | 3.31 |

| R-32 | ~3.4 |

| R-290 (Propane) | ~3.4 |

| Hydrocarbons | 3.3 – 3.5 |

| SF₆ | 10.5 |

Gases like oxygen and nitrogen, which do not absorb infrared light, cannot be detected by NDIR.

NDIR CO2 Sensor

NDIR CH4 Sensor

MH-T4041A Low Power Consumption Infrared Gas Sensor

- Hydrocarbon flammable gases

- 0~10% Vol optional(refer to sheet 2)

- Read More

NDIR Refrigerant Sensor

NDIR SF6 Sensor

4. Advantages of NDIR Sensors

High Selectivity

Only absorbs IR light at specific wavelengths — minimizing cross-sensitivity.

Long-Term Stability

No chemical reaction occurs, ensuring stable performance for 5–15 years.

Low Maintenance

No consumables or frequent calibration needed for many models.

Fast Response Time

Typical response times are <30 seconds for CO₂ and similar gases.

Wide Measurement Range

Can detect from ppm (parts per million) to percent levels.

Insensitive to Poisoning

Unlike electrochemical sensors, NDIR is not affected by chemical poisoning.

5. Limitations of NDIR Sensors

Limited to IR-Active Gases

Cannot detect gases like O₂, H₂, or noble gases.

Affected by Temperature and Humidity

May require temperature and humidity compensation in some cases.

Optical Contamination

Dust or condensation in the optical path can affect measurement accuracy.

Higher Initial Cost

Generally more expensive than electrochemical or MOS sensors.

6. Types of NDIR Sensor Designs

6.1 Single-Beam vs Dual-Beam NDIR

| Type | Description | Advantage |

|---|---|---|

| Single-Beam | One IR source and one detector | Cost-effective |

| Dual-Beam | Adds a reference channel | More stable over time |

6.2 Dispersive vs Non-Dispersive

Dispersive IR sensors use prisms or gratings, while NDIR (non-dispersive) uses optical filters — making NDIR simpler and more compact.

7. Applications of NDIR Sensors

7.1 Indoor Air Quality Monitoring

- CO₂ monitoring in schools, offices, and homes

- Used in HVAC systems for demand-controlled ventilation

7.2 Refrigerant Leak Detection

- Detects flammable refrigerants like R-32, R-290, and R-1234yf

- Complies with ASHRAE 15 and EN 378 standards

7.3 Automotive and Transportation

- Cabin CO₂ sensors for comfort and safety

- Monitoring exhaust gases in emissions testing

7.4 Industrial Safety

- Monitoring CO and CH₄ in factories, mines, and confined spaces

7.5 Greenhouse and Agriculture

- CO₂ control in greenhouses for plant growth

- Detects methane from fermentation or livestock

7.6 Environmental Monitoring

- Ambient air CO₂ for climate change studies

- CH₄ detection for leakage in oil & gas fields

8. Calibration and Maintenance

8.1 Calibration

- Most NDIR sensors are factory-calibrated

- Auto-calibration available in some models

- Optional manual span/gain adjustment for accuracy in critical applications

8.2 Maintenance Tips

- Keep optical path clean and dry

- Avoid exposure to dust or corrosive gases

- Use filters or membranes if measuring in dirty environments

9. Recent Advances in NDIR Technology

Miniaturization

Micro-NDIR sensors now fit into compact devices like IoT nodes and wearable instruments.

MEMS-Based IR Sources

Low-power, fast-heating micro-emitters reduce energy consumption.

Integrated Compensation Algorithms

Modern sensors include on-chip temperature and pressure correction.

Wireless Integration

NDIR sensors now connect via BLE, LoRa, Zigbee, and other wireless protocols.

10. Key Performance Specifications

| Parameter | Typical Range |

|---|---|

| Measurement Range | 0–2000 ppm to 0–100% vol |

| Accuracy | ±(50 ppm + 3% of reading) |

| Response Time (T90) | < 30 seconds |

| Warm-Up Time | 30 seconds to 2 minutes |

| Operating Temperature | -10°C to 60°C (extended ranges available) |

| Lifetime | 5 to 15 years |

| Output | Analog (0–5V, 4–20 mA), Digital (UART, I²C, Modbus) |

11. How to Select the Right NDIR Sensor

When choosing an NDIR sensor, consider:

- Target Gas and Range

- Accuracy Requirements

- Environmental Conditions

- Response Time

- Output Signal Type

- Power Supply and Size

- Certification (UL, ATEX, RoHS)

12. Comparison: NDIR vs Other Gas Sensing Technologies

| Feature | NDIR | Electrochemical | Semiconductor (MOS) |

|---|---|---|---|

| Gas Selectivity | High | Medium | Low |

| Long-Term Stability | Excellent | Moderate | Poor |

| Power Consumption | Low (modern designs) | Low | Moderate–High |

| Cost | Medium–High | Low–Medium | Low |

| Sensitivity to Poisoning | No | Yes | Yes |

| Response Time | Moderate–Fast | Fast | Very Fast |

| Maintenance | Low | Medium | High |

13. FAQs About NDIR Sensors

Q1: Can NDIR sensors detect oxygen?

No. Oxygen does not absorb IR radiation and cannot be detected with NDIR.

Q2: Do NDIR sensors need regular calibration?

Not usually. Many come with auto-calibration features, but manual calibration improves accuracy in critical applications.

Q3: Are NDIR sensors explosion-proof?

Some models are certified for ATEX or IECEx and are suitable for hazardous environments.

Q4: Can NDIR sensors be used in outdoor applications?

Yes, but they must be protected from rain, dust, and temperature extremes.

Q5: How long do NDIR sensors last?

Typical lifespan is 5–15 years, depending on use and environment.

14. Conclusion

NDIR sensors represent a mature, accurate, and dependable technology for detecting infrared-absorbing gases. Their non-contact measurement method, long-term stability, and low maintenance make them ideal for a broad range of applications, from indoor CO₂ monitoring to industrial refrigerant leak detection.

With ongoing advances in miniaturization, digital output, and IoT integration, NDIR sensors continue to evolve, offering higher precision, lower power consumption, and broader usability.