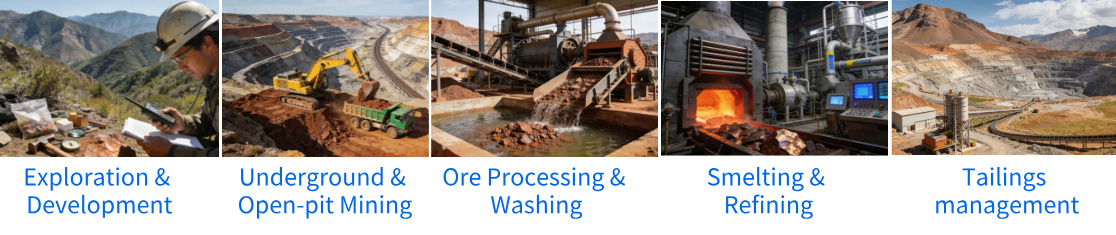

1. Exploration & Development

During exploration drilling and mine development, sensors help engineers evaluate gas risk, stabilize drilling processes and prepare for safe production.

Key sensor applications

- Gas sensors – monitoring combustible and toxic gases inside boreholes, such as methane (CH₄) and hydrogen sulfide (H₂S), to prevent explosions and poisoning.

- Pressure sensors – tracking drilling fluid pressure to prevent kick and blowout accidents, and to protect pumps and pipelines.

Recommended models

- MH-T7042A – compact NDIR gas sensors for methane monitoring in drilling cabins and mud-logging units.

- ZE03 multi-gas modules – electrochemical gas modules for SO₂, H₂S, O₂, CO, NO₂, NH₃ and other toxic gases.

- WPCK07 / WPCK81 / WPCK62– pressure transmitters for drilling fluid, pump discharge and manifold pressure monitoring.