NH3 Sensor Available Worldwide

Winsen's NH3 sensors are available globally, offering reliable ammonia detection with advanced technology. Suitable for industrial, agricultural, and environmental use, our sensors deliver high sensitivity and stability, backed by worldwide shipping and support.

NH3 Gas Sensor Specifications

Winsen's NH3 gas sensors feature tailored specifications, including multiple detection principles (electrochemical, semiconductor, MEMS), wide range options (0-1000ppm), and stable performance, meeting diverse application needs with precision.

| Model | Detection Principle | Characteristics | Target Gas | Detection Range | Size (L×W×H) |

|---|---|---|---|---|---|

MQ137 |

Semiconductor | High sensitivity, low power consumption, suitable for portable detectors | NH3 | 5-500ppm | φ20×22mm |

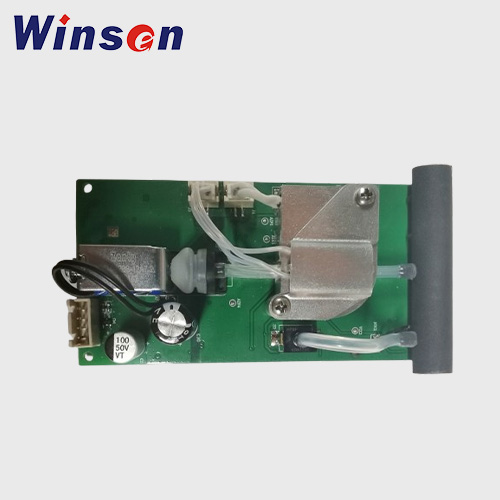

ZE03-NH3 |

Module, Electrochemical | UART & analog output, for portable/fixed detectors | NH3 | 5-500ppm | ø23.5×24.5mm |

UE-NH3 |

Electrochemical | High accuracy, stable performance, industrial-grade | NH3 | 0~100ppm | φ18×16mm |

ME4-NH3 |

Electrochemical | Low drift, long lifespan, suitable for harsh environments | NH3 | 0-50ppm, Max 200ppm | φ20×17mm |

ME3-NH3 |

Electrochemical | Fast response, high repeatability, environmental monitoring | NH3 | 0-100ppm, Max 200ppm | φ20×16.4mm |

MP-702 |

Semiconductor | Small size, easy integration, consumer electronics | NH3 | 0-100ppm | 12×12×8mm |

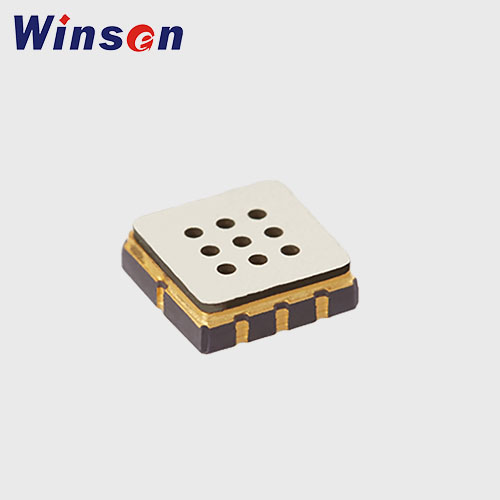

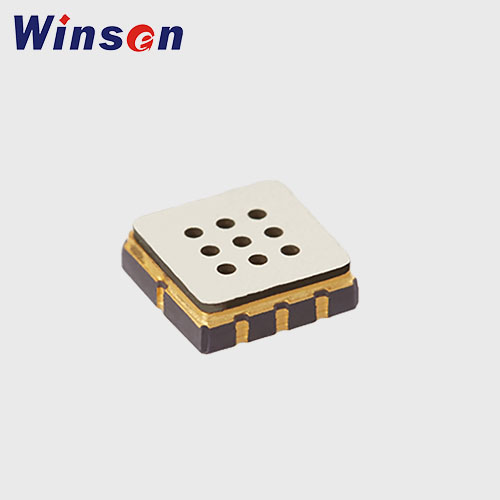

GM-802B |

MEMS, Semiconductor | Ultra-small size, low power, IoT devices | NH3 | 1-300ppm | 8×8×3mm |

ZE801-NH3 |

Module, Electrochemical | Odor detection, air quality monitors, smart home | NH3 | 0~50PPM | 22×20×6mm |

Get Factory Price And Free Samples Right Now!

Get factory-direct pricing on Winsen NH3 sensors and claim free samples today. Fast quotes, quick delivery, and custom solutions available—ideal for prototyping or bulk orders, with dedicated support to meet your requirements.

LET'S TALK

Free Get Price

NH3 Gas Sensor Advantages

Winsen's NH3 gas sensors provide reliable and accurate ammonia detection for various industrial and environmental applications. With advanced electrochemical technology, our sensors offer excellent sensitivity and stability.

High Detection Precision

Adopt advanced electrochemical core, measurement error ≤±3% FS, ensure accurate data collection even in low concentration environments.

Get PriceStrong Stability

Unique anti-interference design, effectively resist H2S, CO and other gases interference; zero drift ≤0.5% FS/month, long-term reliable operation.

Get PriceLong Service Life

High-quality electrolyte and electrode materials, electrochemical sensors lifespan up to 2-3 years, MEMS sensors up to 5 years, reduce replacement costs.

Get PriceWide Compatibility

Support UART, I2C, analog voltage multiple output interfaces; working voltage 3.3V-5V, easy integration into various detection devices and IoT systems.

Get PriceApplications of NH3 Sensors

NH3 sensors from Winsen are widely used in agriculture (livestock farms), chemical industry (leak detection), refrigeration, environmental monitoring, and indoor air quality, ensuring safety and efficiency across sectors.

Agricultural Livestock Farming

Monitor ammonia concentration in livestock houses (pig farms, chicken farms) in real-time. When NH3 exceeds 50ppm, trigger ventilation systems automatically to improve animal living environment, reduce disease incidence and increase breeding efficiency.

Chemical & Pharmaceutical Industry

Used in ammonia storage tanks, production workshops and pipelines leakage detection. With alarm function, it can promptly warn when concentration exceeds 25ppm, preventing poisoning accidents and ensuring production safety.

Environmental Protection Monitoring

Integrated into outdoor air quality monitoring stations or mobile detection vehicles to track ammonia emissions from industrial waste gas and agricultural sources, providing data support for environmental governance and policy formulation.

Cold Chain & Refrigeration

Ammonia is a common refrigerant. Sensors installed in cold storage and refrigeration equipment detect leakage early (detection limit ≤1ppm), avoid refrigerant loss and equipment damage, and ensure food safety in cold chain transportation.

Medical & Health Field

Used in hemodialysis rooms and laboratory ammonia gas monitoring. Ammonia exceeding 10ppm will affect medical equipment accuracy and human health. The sensor can realize 24-hour continuous monitoring and data recording.

Indoor Air Quality

Integrated into smart air purifiers or home monitoring devices to detect ammonia released from decoration materials (paint, wallpaper) and daily chemicals. When concentration is higher than 5ppm, start purification function automatically.

NH3 Sensor (Ammonia Gas Sensor) – Complete Guide

Ammonia (NH₃) is a colorless gas with a strong and pungent odor, widely used in agriculture, refrigeration, chemical industries, and environmental monitoring. While ammonia is an essential chemical for fertilizers and industrial processes, it is also highly toxic in high concentrations. Exposure to ammonia can cause respiratory irritation, eye damage, and even life-threatening health issues.

This is where an NH3 sensor (Ammonia Sensor) plays a crucial role. NH3 sensors are designed to detect and monitor ammonia concentrations in the air, ensuring safety, process efficiency, and environmental protection.

1. What is an NH3 Sensor?

An NH3 sensor, also known as an ammonia sensor or ammonia gas detector, is an electronic device used to measure the concentration of ammonia gas in the air. These sensors are used in:

The sensor continuously monitors ammonia levels and outputs an electrical signal proportional to the gas concentration, which can be read by monitoring equipment or integrated into safety systems.

2. Working Principles of NH3 Sensors

Winsen's NH3 sensors mainly adopt three core technologies, each with unique advantages for different application scenarios:

Electrochemical Principle

Ammonia gas reacts with electrolyte on the working electrode, generating an electrical current proportional to concentration. Features high accuracy, good selectivity, suitable for industrial-grade detection (e.g., UE-NH3, ME4-NH3).

Semiconductor Principle

Ammonia gas changes the resistance of metal oxide semiconductor materials. Advantages include small size, low cost, fast response, ideal for consumer electronics (e.g., MQ137, MP-702).

MEMS Technology

Miniaturized semiconductor sensor based on MEMS process. Ultra-low power consumption, tiny volume, perfect for IoT and portable devices (e.g., GM-802B).

3. Key Parameters to Consider When Selecting NH3 Sensors

| Parameter | Description | Selection Suggestion |

|---|---|---|

| Detection Range | The concentration interval that the sensor can measure | Livestock farming: 0-500ppm; Industrial leakage: 0-100ppm; Indoor: 0-50ppm |

| Accuracy | Deviation between measured value and true value | Industrial detection: ≤±3% FS; General monitoring: ≤±5% FS |

| Response Time | Time to reach stable reading after gas contact | Emergency detection: ≤10s; Routine monitoring: ≤30s |

| Operating Environment | Temperature, humidity range suitable for work | Outdoor: -40℃~85℃; Indoor: 0℃~50℃; Humidity: 10%~95% RH (no condensation) |

| Output Interface | Signal output method of the sensor | IoT devices: UART/I2C; Analog devices: 0-5V/4-20mA |

4. Installation & Maintenance Tips

Installation Notes:

Maintenance Suggestions:

FAQs About NH3 Sensors

Find answers to common questions about NH3 sensors, including safety thresholds, calibration, and customization. Winsen's expert insights help solve technical and application challenges.

According to OSHA standards, the 8-hour time-weighted average (TWA) safe concentration of ammonia for humans is 25ppm, and the short-term exposure limit (STEL) is 35ppm. When the concentration exceeds 50ppm, it will cause obvious eye and respiratory tract irritation; concentrations above 300ppm may lead to severe poisoning or even death.

Electrochemical sensors have high accuracy (≤±3% FS) and strong selectivity, but higher cost and shorter lifespan (2-3 years), suitable for industrial precision detection. Semiconductor sensors are cheap, small in size and have a long lifespan (3-5 years), but accuracy is slightly lower (≤±5% FS) and easy to be interfered by other gases, suitable for consumer electronics and general monitoring scenarios.

Most of Winsen's NH3 sensors can work in environments with 10%-95% RH (no condensation). For high-humidity scenarios such as livestock houses and wastewater treatment plants, we recommend selecting sensors with waterproof and anti-condensation design (e.g., ME4-NH3 with PTFE filter membrane). Avoid long-term immersion in water or working under condensation conditions, which will affect sensor performance and lifespan.

Calibration requires the use of standard ammonia gas with known concentration. The steps are: 1. Place the sensor in clean air for 30 minutes to zero; 2. Introduce standard gas (usually 50% of the full range) and stabilize for 10 minutes; 3. Adjust the sensor output value to match the standard gas concentration. The calibration cycle is usually 6-12 months; for harsh environments with high dust and high humidity, it is recommended to shorten to 3-6 months.

Yes. Winsen can provide customized services according to customer needs, including adjusting detection range (e.g., 0-20ppm for indoor use, 0-1000ppm for industrial use), customizing output interface (UART/I2C/4-20mA), modifying product size for equipment integration, and developing matching detection modules with alarm functions. Welcome to contact our sales team for detailed customization plans.