Carbon Monoxide (CO) Sensor: Principles, Types, and Applications

1. Introduction

Carbon monoxide (CO) is an invisible, odorless, and tasteless gas that can be deadly even in small concentrations. It is produced by the incomplete combustion of carbon-containing fuels like natural gas, coal, wood, and gasoline.

To prevent poisoning and ensure safety, Carbon Monoxide (CO) Sensors are installed in homes, vehicles, industrial facilities, and public buildings. These sensors continuously monitor air for the presence of CO gas and trigger alarms or ventilation systems when dangerous levels are detected.

2. What is Carbon Monoxide (CO)?

Carbon monoxide is a toxic gas (chemical formula: CO) formed when fuel burns incompletely due to insufficient oxygen. Common sources include:

- Furnaces

- Gas stoves and ovens

- Fireplaces and wood stoves

- Generators and engines

- Vehicle exhausts

- Charcoal grills

CO Exposure Effects:

| Concentration (ppm) | Health Effect |

|---|---|

| 0–9 | Normal indoor air levels |

| 10–50 | Headaches, fatigue after long exposure |

| 100–200 | Dizziness, nausea, mild symptoms in 1–2 hours |

| 400+ | Potentially fatal within 3 hours |

| 800+ | Death within 1–2 hours without prompt intervention |

3. What is a CO Sensor?

A carbon monoxide sensor is an electronic device that detects the presence of carbon monoxide gas in the air and provides a digital or analog output. These sensors are critical for safety and environmental monitoring.

They can be found in:

- Smoke and gas detectors

- Smart thermostats

- HVAC systems

- Industrial safety equipment

- Vehicles and parking garages

4. Why is CO Detection Important?

- CO is called the "silent killer" due to its undetectable nature.

- It binds to hemoglobin in the blood, reducing oxygen delivery to the brain and body.

- Common in both residential and industrial environments.

- Prevents accidental poisoning and property damage.

- Enables automated ventilation or emergency alerts in modern systems.

5. Working Principles of CO Sensors

The main detection mechanisms include:

| Principle | Description |

|---|---|

| Electrochemical | Measures electrical current generated by a redox reaction with CO |

| Semiconductor (MOS) | Sensing layer changes resistance in presence of CO |

| Infrared (NDIR) | Detects gas absorption of infrared light at specific CO wavelengths |

| Colorimetric | Uses a chemical patch that changes color upon contact with CO |

Electrochemical sensors are the most widely used due to high accuracy, selectivity, and low power consumption.

6. Types of CO Sensors

1. Electrochemical CO Sensors

- High sensitivity and accuracy

- Low power consumption

- Ideal for battery-powered detectors

2. Semiconductor (MOS) CO Sensors

- Durable and low-cost

- Requires heating element (higher power consumption)

- Used in general air quality monitors

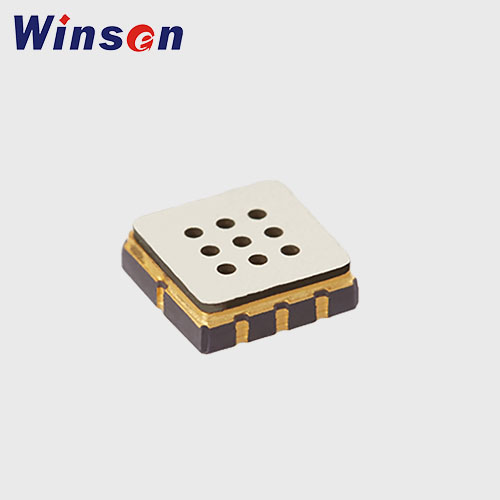

MP-9 CO/CH4 Semiconductor Flat Surfaced Gas Sensor

- CO,CH4

- 50-1000ppm(CO),300-10000ppm(CH4)

- Read More

3. Infrared (NDIR) CO Sensors

- Non-contact, long-life

- High accuracy and fast response

- Common in industrial and commercial systems

4. Colorimetric CO Sensors

- Passive indicators with color change

- No electronics

- Used for spot detection and disposable badges

7. Key Components of a CO Sensor

- Sensing Element: Converts gas concentration into an electrical signal

- Microcontroller Unit (MCU): Processes and interprets the signal

- Analog/Digital Interface: Outputs concentration readings

- Alarm or Relay Output: Activates in high CO presence

- Display (optional): Shows real-time CO levels

Some modules include wireless connectivity (Wi-Fi, Zigbee) for smart integration.

8. CO Sensor Specifications

| Parameter | Typical Range |

|---|---|

| Measurement Range | 0–1000 ppm or 0–2000 ppm |

| Accuracy | ±3–5% of reading |

| Response Time (T90) | < 60 seconds |

| Operating Temperature | –10°C to +50°C (varies by sensor) |

| Power Supply | 3.3V–24V (depending on sensor type) |

| Output Type | Analog (mV), I²C, UART, Modbus, 4–20mA |

| Sensor Life Span | 2–5 years (electrochemical) |

9. CO Sensor Calibration and Maintenance

Calibration

- Required every 6–12 months for accurate readings

- Calibrated using known CO gas concentration

- Some advanced models include auto-calibration

Maintenance

- Clean regularly

- Check expiration date

- Replace sensor unit when sensitivity drops

- Avoid exposure to extreme humidity and temperatures

10. Sensor Placement and Installation Guidelines

Proper placement is crucial:

- Height: Install at eye-level for living areas or ceiling-mounted in garages

- Avoid placing near stoves, vents, or humidifiers

- Multiple sensors for large or multi-level spaces

- Install near sleeping areas, furnaces, and attached garages

- Follow manufacturer’s instructions and local building codes

11. Applications of CO Sensors

Residential

- CO alarms and smoke detectors

- Smart home integration

- Portable travel detectors

Commercial Buildings

- HVAC and BMS systems

- Indoor air quality monitoring

- Parking structures and loading docks

Industrial

- Boilers and gas-powered machinery

- Chemical plants

- Mining operations

Automotive and Transport

- Fleet monitoring

- In-vehicle safety systems

- Tunnels and subway systems

Healthcare

- Medical gas systems

- Oxygen generators and hospital environments

12. CO Sensor Standards and Regulations

| Standard | Organization | Scope |

|---|---|---|

| UL 2034 | Underwriters Laboratories | Residential CO alarms |

| EN 50291 | European Standard | CO detectors for domestic use |

| OSHA PEL | Occupational Safety | CO limit: 50 ppm (8-hour exposure) |

| NIOSH REL | US Health Institute | Recommended limit: 35 ppm |

| CSA 6.19 | Canadian Standards Assoc | CO alarm performance |

13. Challenges in CO Detection

- Sensor Drift: Electrochemical sensors degrade over time

- Cross-Sensitivity: Some sensors react to hydrogen or alcohol vapors

- False Alarms: Triggered by cooking appliances or cigarette smoke

- Environmental Interference: Humidity, temperature swings, and airflow can affect accuracy

- Maintenance: Periodic calibration and replacement needed

14. Integration with Smart Systems and IoT

Modern CO sensors can:

- Send alerts to smartphones or control systems

- Trigger smart exhaust fans or HVAC adjustments

- Be accessed remotely via cloud dashboards

- Support platforms like HomeKit, Google Home, or Alexa

Integration with IoT allows:

- Real-time analytics

- Predictive maintenance

- Historical data storage and compliance tracking

15. CO Sensor in HVAC and BMS

CO sensors are often integrated into:

- Building Management Systems (BMS)

- Demand-Controlled Ventilation (DCV)

- Fresh air systems

- Garage ventilation

Benefits:

- Improves air quality

- Reduces energy consumption

- Complies with indoor air quality regulations

16. Frequently Asked Questions (FAQs)

Q1: How long does a CO sensor last?

Most electrochemical CO sensors last 2–5 years, depending on quality and environment.

Q2: Do CO detectors detect natural gas leaks?

No. CO detectors only detect carbon monoxide, not methane or propane.

Q3: Are CO sensors mandatory in homes?

Yes, in many countries and states, CO detectors are legally required in homes with fuel-burning appliances.

Q4: Can a CO detector detect fire?

No. It may alert to CO from incomplete combustion, but it’s not a substitute for a smoke detector.

Q5: What is the safe level of CO in air?

- 0–9 ppm: Normal

- <50 ppm: Safe for limited exposure

- > 100 ppm: Dangerous, action needed

17. Conclusion

Carbon Monoxide (CO) Sensors are vital devices that safeguard lives and property from the dangers of CO gas exposure. Available in a range of technologies and configurations, these sensors are widely used in residential, industrial, automotive, and commercial applications.

With the increasing trend of smart homes, IoT-enabled HVAC systems, and regulatory mandates, CO sensors are no longer optional — they are critical components in modern building safety and environmental monitoring systems.