Hydrogen (H₂) Sensor: Types, Applications, and Technology Insights

Introduction to Hydrogen and the Need for H₂ Sensors

Hydrogen (H₂) is a colorless, odorless, and highly flammable gas widely used in various industries such as energy, chemicals, transportation, and electronics. With the global push toward cleaner energy and decarbonization, hydrogen has emerged as a key player in the green energy transition, particularly in fuel cells, hydrogen-powered vehicles, and renewable energy storage systems.

However, hydrogen’s flammable nature and its ability to form explosive mixtures with air (at concentrations between 4% and 75% by volume) make hydrogen leak detection essential for operational safety. This is where hydrogen sensors—or H₂ sensors—come into play. These sensors are designed to detect the presence and concentration of hydrogen gas in ambient air, triggering safety mechanisms or alerts to prevent accidents and explosions.

What Is a Hydrogen Sensor?

A hydrogen sensor is a gas detector that identifies the presence of hydrogen in air or gas mixtures. It typically outputs an analog or digital signal proportional to the hydrogen concentration and can be integrated with monitoring systems or alarms. Hydrogen sensors are used in industrial environments, automotive fuel systems, laboratories, refineries, aerospace, and hydrogen storage facilities.

How Do Hydrogen Sensors Work?

Hydrogen sensors work by detecting changes in physical, chemical, or electrical properties when exposed to hydrogen gas. The working principle varies based on the sensor type, which includes electrochemical, catalytic, semiconductor (metal oxide), thermal conductivity, and optical sensors.

Key Detection Principles:

| Sensor Type | Detection Mechanism |

|---|---|

| Catalytic Combustion | Oxidation of H₂ produces heat; change in resistance is measured. |

| Electrochemical | H₂ oxidizes on an electrode, generating measurable current. |

| Metal Oxide Semiconductor (MOS) | H₂ reduces metal oxides, altering electrical conductivity. |

| Thermal Conductivity | H₂'s high thermal conductivity affects heat dissipation. |

| Optical Sensors | Light absorption or reflection changes in the presence of H₂. |

Types of Hydrogen Sensors

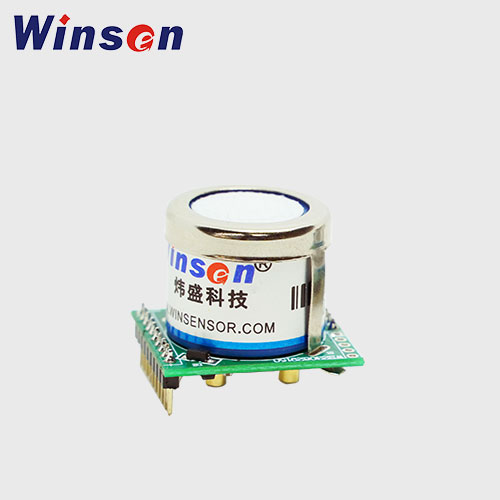

1. Electrochemical Hydrogen Sensors

Electrochemical sensors detect hydrogen by facilitating redox reactions on an electrode. They offer high accuracy and low power consumption, making them suitable for portable and fixed detection systems.

Advantages:

- High sensitivity

- Low power consumption

- Good selectivity

- Stable operation in varying temperatures

Limitations:

- Limited lifetime (usually 1–3 years)

- Sensitive to high humidity

EC Hazardous Toxic Gas Detection Sensor Module ZE03

- CO,O2,NH3,H2S,NO2,O3,SO2, CL2,HF,H2,PH3,HCL, etc.

- See manual

- Read More

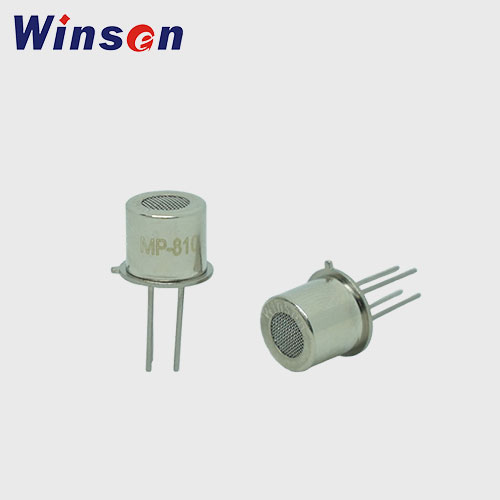

2. Catalytic Bead Sensors

These detect hydrogen through catalytic combustion. Hydrogen burns on a heated bead coated with a catalyst, causing a temperature rise and a change in resistance.

Advantages:

- Robust and time-tested technology

- Suitable for explosive concentration detection

Limitations:

- Requires oxygen for detection

- Consumes more power

- May get poisoned by silicones or sulfur compounds

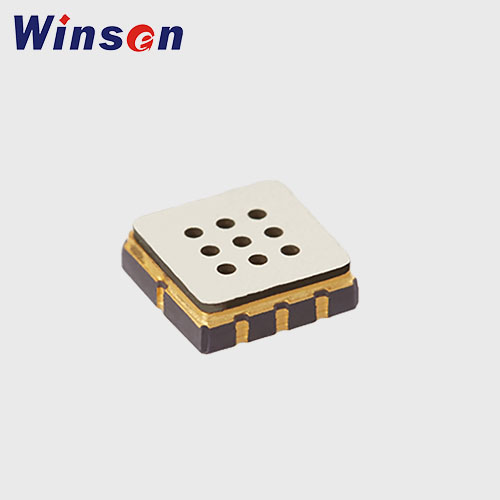

3. MOS (Semiconductor) Hydrogen Sensors

MOS sensors use metal oxide materials such as tin dioxide (SnO₂) that change resistance in the presence of hydrogen.

Advantages:

- Fast response

- Cost-effective

- Compact size

Limitations:

- Cross-sensitivity to other gases (e.g., CO, CH₄)

- Affected by humidity and temperature

4. Thermal Conductivity Sensors

These detect hydrogen based on its high thermal conductivity relative to air. When exposed to H₂, the sensor’s heat loss changes, which is measurable.

Advantages:

- Long lifespan

- Stable over time

Limitations:

- Poor selectivity

- Requires temperature compensation

5. Optical Hydrogen Sensors

These use materials that change optical properties (absorption, reflectance) in the presence of hydrogen. They are often used in harsh or remote environments.

Advantages:

- Intrinsically safe

- Immune to electromagnetic interference

- Suitable for remote sensing

Limitations:

- Expensive

- May require complex signal processing

Applications of Hydrogen Sensors

Hydrogen sensors are critical in both conventional and emerging technologies. Key application areas include:

1. Hydrogen Fuel Cells

In fuel cell vehicles (FCVs), hydrogen sensors are used to detect leaks in tanks, pipelines, and fuel systems to prevent fire or explosion.

2. Industrial Gas Plants

H₂ sensors monitor hydrogen levels in chemical plants, ammonia synthesis, petroleum refining, and metal processing industries.

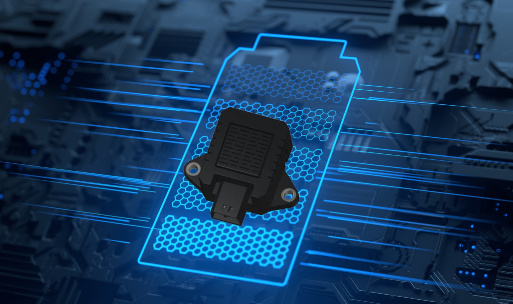

3. Battery and Energy Storage

In large-scale battery systems (e.g., nickel-metal hydride or lithium-ion), sensors detect hydrogen buildup to prevent pressure build-up or explosion.

4. Aerospace and Aviation

Hydrogen is used as a rocket fuel; sensors are installed in ground support equipment and spacecraft for early leak detection.

5. Smart Buildings

Hydrogen sensors are integrated into safety systems in laboratories, gas storage rooms, and backup power systems.

6. Hydrogen Refueling Stations

Monitoring leaks and ventilation status ensures safe hydrogen delivery to vehicles.

Key Features of a Good Hydrogen Sensor

When selecting a hydrogen sensor for commercial or industrial use, the following specifications are critical:

| Feature | Description |

|---|---|

| Detection Range | Commonly 0–1000 ppm, 0–4% vol, or up to LEL (Lower Explosive Limit) |

| Response Time | Ideally under 10 seconds |

| Operating Temperature | Wide range (-20°C to +60°C or more) |

| Humidity Range | Tolerant of 0–95% RH (non-condensing) |

| Output Format | Analog (mV, 4–20 mA) or Digital (UART, I²C, Modbus, CAN) |

| Power Consumption | Varies by type; electrochemical uses less than semiconductor or catalytic |

| Explosion Proof | ATEX/IECEx rated for hazardous locations |

| Lifespan | Typically 2–5 years depending on type and use |

Safety and Regulatory Compliance

Because hydrogen is classified as a flammable gas, sensor installations must comply with industry safety standards such as:

- ATEX (Atmosphères Explosibles)

- IECEx (International Electrotechnical Commission System for Certification)

- UL and CSA certifications for North America

- RoHS/REACH compliance for environmental safety

Proper placement, calibration, and maintenance are critical to ensure reliable performance. For high-risk environments, redundancy using different sensor types is often recommended.

Integration in Modern Systems

Hydrogen sensors can be embedded into smart systems with features such as:

- Wireless communication (LoRa, Zigbee, Wi-Fi)

- IoT cloud integration

- Mobile app notifications

- Self-diagnostic and calibration alerts

- Battery backup for power failure scenarios

Hydrogen Sensor in Valxsen Product Line (Example)

Model: VH2-E100

| Parameter | Specification |

|---|---|

| Detection Gas | Hydrogen (H₂) |

| Detection Range | 0–1000 ppm / 0–4% vol |

| Sensor Type | Electrochemical |

| Response Time (T90) | <15 seconds |

| Output | 4–20 mA / UART |

| Power Supply | 5V / 12V / 24V |

| Operating Temp | -20°C to +60°C |

| Humidity Range | 0–95% RH |

| Certifications | CE, RoHS, ATEX optional |

| Applications | Fuel cells, storage rooms, battery packs |

Frequently Asked Questions (FAQs)

Q1: Is hydrogen sensor calibration necessary?

Yes. Regular calibration (every 6–12 months) ensures accuracy and reduces false positives/negatives.

Q2: Can hydrogen sensors detect other gases?

Some sensor types like MOS may respond to gases like methane or carbon monoxide. Electrochemical sensors generally have better selectivity.

Q3: Are hydrogen sensors explosion-proof?

They can be. For use in hazardous areas, choose ATEX or IECEx certified models.

Q4: What is the LEL of hydrogen?

The Lower Explosive Limit (LEL) for hydrogen is 4% by volume in air.

Q5: How long does a hydrogen sensor last?

Sensor life ranges from 2 to 5 years depending on the sensor type and usage environment.

Conclusion

Hydrogen sensors play a pivotal role in ensuring the safe use of hydrogen across a wide range of applications. As hydrogen becomes more integral to clean energy systems and industrial innovation, the demand for reliable, accurate, and safe hydrogen sensing technology continues to grow. By understanding the different types of hydrogen sensors and their respective advantages, industries can make informed decisions to protect personnel, property, and the environment.

Whether you’re deploying sensors in a hydrogen refueling station, fuel cell vehicle, or industrial plant, choosing the right H₂ sensor—like those from Valxsen—can significantly enhance safety and performance.