Semiconductor (MOS) CO Sensors: Working Principles, Design, and Applications

1. Introduction

Carbon monoxide (CO) is a colorless, odorless, and toxic gas commonly produced by incomplete combustion. To detect and mitigate the risks of CO exposure in both residential and industrial environments, Semiconductor-based gas sensors, also known as MOS (Metal Oxide Semiconductor) sensors, offer a cost-effective and robust solution for CO detection.

MOS CO sensors are widely used due to their simplicity, sensitivity, durability, and low cost, especially in portable detectors, automotive safety systems, and air quality monitors.

2. What is a Semiconductor (MOS) Sensor?

A Semiconductor Gas Sensor detects gas concentration based on changes in the electrical resistance of a metal oxide semiconductor material, typically tin dioxide (SnO₂) or zinc oxide (ZnO), when exposed to a target gas.

They are also referred to as:

- MOS gas sensors

- Chemoresistive gas sensors

- Metal oxide sensors

These sensors are highly effective for detecting reducing gases like CO, H₂, CH₄, and alcohol vapors.

3. Overview of Carbon Monoxide (CO)

Carbon monoxide is a byproduct of incomplete combustion of carbon-based fuels. It poses serious health hazards:

| CO Concentration | Exposure Time | Symptoms |

|---|---|---|

| 50 ppm | 8 hours | Slight headache |

| 200 ppm | 2–3 hours | Fatigue, nausea |

| 400 ppm | 1–2 hours | Dizziness, confusion |

| 800 ppm+ | <1 hour | Unconsciousness, death |

Due to its toxic nature and invisibility, continuous monitoring using CO sensors is essential.

4. What is a Semiconductor (MOS) CO Sensor?

A Semiconductor CO Sensor is a gas detection device that uses a metal oxide sensing layer whose resistance changes in the presence of CO gas. The change in resistance is measured and converted into an electrical signal indicating the CO concentration in air.

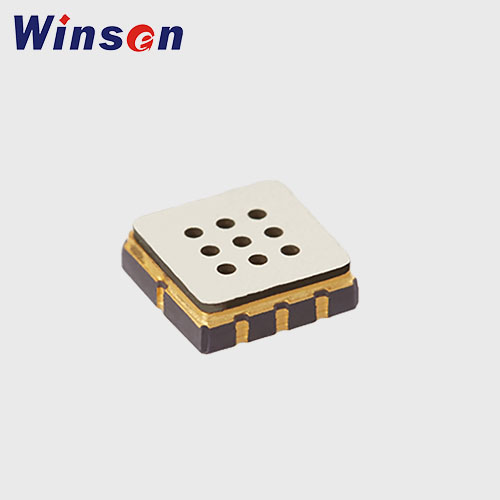

![]()

MOS CO sensors are:

- Inexpensive

- Small in size

- Durable

- Widely used in both consumer and industrial electronics

Winsen Semiconductor (MOS) CO Sensor

MP-9 CO/CH4 Semiconductor Flat Surfaced Gas Sensor

- CO,CH4

- 50-1000ppm(CO),300-10000ppm(CH4)

- Read More

5. Working Principle

The operation of a MOS CO sensor relies on adsorption and redox reactions on a heated semiconductor surface.

Key Reactions:

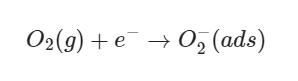

- In clean air (oxygen-rich), oxygen molecules adsorb on the sensor surface, trapping electrons from the conduction band of the n-type semiconductor, increasing resistance:

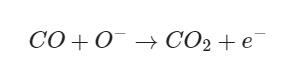

- When CO is introduced, it reacts with the adsorbed oxygen ions, releasing electrons back, thereby decreasing resistance:

- The sensor measures the change in resistance, which is proportional to CO concentration.

6. Sensor Structure and Materials

Basic Structure:

- Substrate: Usually alumina or ceramic.

- Sensing Layer: Tin oxide (SnO₂), ZnO, or other metal oxides.

- Heater: Maintains required operating temperature (~200–400°C).

- Electrodes: Gold or platinum contacts measure resistance.

- Protective Cap: Includes filter to block dust and humidity.

Material Properties:

- SnO₂: Most commonly used due to its high reactivity to reducing gases.

- Doping: Elements like Pd, Pt, or Au improve sensitivity/selectivity.

- Nanostructures: Nanowires, nanotubes, or nanoparticles enhance surface area.

7. Key Specifications

| Parameter | Typical Values |

|---|---|

| Detection Range | 10 – 1000 ppm CO |

| Sensitivity | ≥10 mV/ppm (depending on circuit) |

| Response Time (T90) | 10 – 60 seconds |

| Recovery Time | 10 – 60 seconds |

| Operating Temp | 200 – 400°C (sensor core) |

| Power Supply | 2.5V – 5V (sensor), ~150mW heater |

| Output Signal | Resistance (Ω), analog voltage |

| Lifespan | 5 – 10 years (in ideal conditions) |

8. Sensitivity, Selectivity, and Response Time

Sensitivity:

MOS sensors are highly sensitive, especially at ppm levels. Signal levels increase dramatically as CO concentration rises.

Selectivity:

- Inherently low; may respond to ethanol, hydrogen, methane.

- Improved with catalytic filtering layers or AI-based signal analysis.

Response Time:

Fast response (<1 minute) under normal operating conditions, suitable for real-time monitoring.

9. Advantages of MOS CO Sensors

Low Cost – Ideal for mass-produced devices

Long Lifespan – Can last 5–10 years in clean air environments

Wide Detection Range – Can detect low and high ppm levels

Rugged and Durable – Resistant to shock and vibration

High Sensitivity – Detects even trace levels of CO

Miniaturizable – Compatible with MEMS fabrication for compact designs

10. Limitations and Challenges

High Power Consumption – Due to the built-in heater

Low Selectivity – May be affected by other reducing gases

Humidity Sensitivity – High RH affects readings

Requires Warm-up – Needs ~1–2 minutes to stabilize

Temperature Dependent – Accuracy affected by ambient temperature

Non-linear Output – Needs calibration curve fitting

11. Applications of MOS CO Sensors

Consumer Electronics

- Household gas leak detectors

- Smart home systems

- Air purifiers and HVAC monitoring

Industrial

- Combustion control systems

- Fire detection and suppression systems

- Factory and boiler room safety

Automotive

- In-cabin air quality monitoring

- Engine diagnostics

- Parking garage CO monitoring

Public Infrastructure

- Metro and subway safety

- Tunnels and underground stations

- Smart city air quality sensors

12. Comparison with Other CO Sensor Types

| Feature | MOS Sensor | Electrochemical | NDIR (Infrared) |

|---|---|---|---|

| Cost | Low | Moderate | High |

| Power Use | High (heater) | Very Low | Moderate |

| Accuracy | Moderate | High | Very High |

| Cross Sensitivity | High | Low | Very Low |

| Warm-up Time | 1–2 minutes | None | <1 minute |

| Maintenance | Low | Needs recalibration | Very Low |

| Use Case | Home & air quality | Safety systems | Industrial, high-end |

13. Calibration and Drift Management

Calibration Process:

- Requires CO reference gas (~200–500 ppm)

- Output resistance or voltage is recorded

- Calibration curve is generated and stored

Drift Management:

- Regular zero-point calibration

- Software algorithms compensate for ambient temperature/humidity

- Periodic recalibration every 6–12 months

14. Packaging, Mounting, and Electrical Interface

Packaging:

- TO-39 metal can

- SMD (surface-mount)

- Plastic casings for compact modules

Mounting:

- PCB-mounted with through-hole or SMD soldering

- Protective housing may be required for harsh environments

Electrical Interface:

- Analog output (voltage divider circuit)

- UART/I²C (for digital modules)

- Compatible with MCUs like Arduino, ESP32, STM32

15. Smart Integration and IoT Compatibility

MOS CO sensors can be connected to:

- Microcontrollers for edge computing

- IoT platforms via Wi-Fi, Zigbee, or LoRa

- Mobile apps for alerts and data logging

- Building automation systems (BAS/BMS)

Advanced sensor modules include:

- Auto-calibration firmware

- Temperature/humidity compensation

- Bluetooth or NB-IoT connectivity

16. Innovations in Semiconductor Gas Sensing

Recent advances include:

- Nanostructured sensing layers for higher sensitivity

- Hybrid sensors combining MOS and electrochemical layers

- MEMS-based gas sensors for wearable applications

- AI-enhanced data analytics for pattern recognition and gas discrimination

- Self-healing materials to improve long-term stability

17. Frequently Asked Questions (FAQs)

Q1: Can MOS CO sensors be used in battery-powered devices?

Yes, but their power-hungry heaters make them less ideal than electrochemical sensors unless duty-cycled properly.

Q2: How long do MOS CO sensors last?

Typical lifespan is 5 to 10 years, especially in clean, temperature-controlled environments.

Q3: Do they require frequent calibration?

Usually less frequent than electrochemical sensors, but drift over time necessitates occasional recalibration.

Q4: Are they suitable for outdoor use?

Yes, with proper weatherproof casing and humidity filtering.

Q5: Can a MOS sensor differentiate between CO and alcohol vapors?

No. Selectivity is poor, but can be improved with filters or data analysis techniques.

18. Conclusion

Semiconductor (MOS) CO Sensors provide a cost-effective, sensitive, and long-lasting solution for CO gas detection in a wide range of environments. Despite some limitations like high power consumption and cross-sensitivity, they remain a popular choice for air quality monitors, gas leak detectors, and industrial safety systems due to their simplicity and robustness.

As technology advances, we expect better selectivity, miniaturization, and smart features, making MOS sensors even more reliable and adaptable in IoT and real-time environmental monitoring.