Electrochemical HCHO Sensors: Accurate Formaldehyde Detection Technology

Introduction

Formaldehyde (chemical formula: HCHO or CH₂O) is a colorless, pungent-smelling volatile organic compound (VOC) widely used in building materials, adhesives, textiles, and chemical production. Despite its usefulness, formaldehyde is toxic and carcinogenic, making it a major indoor air pollutant. Continuous exposure, even at low levels, can cause irritation, respiratory issues, and long-term health risks.

To address this, electrochemical HCHO sensors have become one of the most reliable and accurate methods for detecting formaldehyde in air. These sensors are designed to provide real-time, selective, and sensitive measurements at ppm or even ppb levels, ensuring safety in homes, workplaces, and industrial environments.

What is an Electrochemical HCHO Sensor?

An electrochemical HCHO sensor is a gas-sensing device that uses electrochemical reactions at electrodes to detect and measure the concentration of formaldehyde.

- The sensor consists of a working electrode, counter electrode, and reference electrode immersed in an electrolyte.

- When formaldehyde gas diffuses into the sensor, it undergoes an oxidation-reduction (redox) reaction at the electrode surface.

- This reaction generates an electrical current proportional to the HCHO concentration.

This principle makes electrochemical sensors highly sensitive and selective to formaldehyde compared to semiconductor or optical alternatives.

Winsen Electrochemical HCHO Sensor

Electrochemical HCHO Formaldehyde Sensor Module ZE08B-CH2O

- CH2O, HCHO, Formaldehyde

- 0~1.6ppm

- Read More

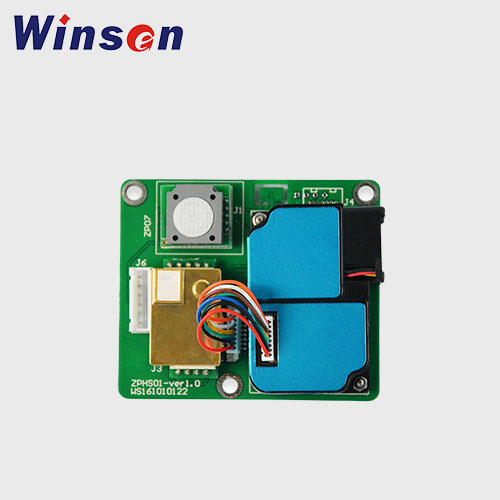

ZPHS01 Multi-in-One Sensor Module (HCHO version)

- CO2, PM2.5, CH2O, VOC, Temperature, Humidity

- CO2: 0-5000ppm; PM2.5: 0-1000μg/m³; CH2O: 0-1.6ppm; VOC: 4 level; Temperature: 0-65℃ (Accuracy±0.5℃); Humidity: 0-100%RH (Accuracy±3%)

- Read More

Working Principle of Electrochemical HCHO Sensors

-

Gas Diffusion

- Formaldehyde molecules enter the sensor through a gas-permeable membrane.

-

Electrochemical Reaction

- At the working electrode, HCHO undergoes oxidation in the presence of a catalyst.

- Example reaction:

$HCHO + H₂O → HCOOH + 2H⁺ + 2e⁻$

-

Current Generation

- The released electrons flow through an external circuit, generating a measurable current.

-

Signal Processing

- The current is directly proportional to the gas concentration.

- Electronics convert the signal into ppm or ppb readings.

Key Features of Electrochemical HCHO Sensors

- High Sensitivity – Capable of detecting low ppb levels of formaldehyde.

- Excellent Selectivity – Minimal cross-sensitivity to other VOCs.

- Low Power Consumption – Ideal for portable and battery-powered devices.

- Linear Output – Simplifies calibration and integration into monitoring systems.

- Long-Term Stability – Provides consistent measurements with proper maintenance.

- Compact Design – Suitable for integration into smart home devices and handheld detectors.

Applications of Electrochemical HCHO Sensors

Electrochemical formaldehyde sensors are widely adopted in:

1. Indoor Air Quality Monitoring

- Smart home devices, air purifiers, and HVAC systems.

- Helps ensure compliance with WHO’s recommended exposure limits.

2. Industrial Safety

- Chemical plants, furniture factories, and textile production sites.

- Protects workers from harmful exposure during manufacturing.

3. Occupational Health

- Personal protective monitoring devices for laboratory and field workers.

- Ensures formaldehyde exposure remains below permissible exposure limits.

4. Environmental Monitoring

- Detects formaldehyde emissions from vehicles and industrial exhausts.

- Supports environmental compliance testing.

5. Smart Cities and IoT Integration

- Wireless IAQ sensors connected to mobile apps or cloud platforms.

- Enables data-driven air quality management.

Advantages of Electrochemical HCHO Sensors

- High Accuracy – Provides precise readings even at low concentrations.

- Low Cross-Interference – Less affected by ethanol, toluene, or other VOCs.

- Energy Efficient – Consumes only a fraction of the power used by semiconductor sensors.

- Fast Response Time – Immediate detection of changing HCHO levels.

- Scalability – Suitable for personal, commercial, and industrial applications.

Limitations of Electrochemical HCHO Sensors

- Finite Lifetime – Typically 1–3 years, depending on usage and environment.

- Calibration Requirement – Needs periodic calibration to maintain accuracy.

- Environmental Sensitivity – Performance may be affected by high humidity or extreme temperatures.

- Cost – Generally more expensive than MOS-based sensors.

Comparison: Electrochemical vs. MOS vs. Optical HCHO Sensors

| Feature | Electrochemical Sensor | MOS Sensor | Optical (PAS/NDIR) Sensor |

|---|---|---|---|

| Sensitivity | Very High (ppb levels) | Medium (ppm levels) | Very High (ppb levels) |

| Selectivity | High | Low (cross-sensitive) | High |

| Power Consumption | Low | Medium-High | Medium |

| Response Time | Fast | Fast | Moderate |

| Cost | Medium-High | Low | High |

| Best For | Professional, IAQ, safety | Low-cost consumer devices | High-end industrial/research |

How to Choose the Right Electrochemical HCHO Sensor

When selecting an electrochemical formaldehyde sensor, consider:

- Detection Range – Ensure it covers required ppb or ppm levels.

- Response Time – Choose fast-response sensors for real-time alerts.

- Accuracy & Selectivity – Look for low cross-interference designs.

- Operating Conditions – Match with expected humidity and temperature ranges.

- Lifetime & Calibration – Balance maintenance requirements with long-term use.

- Integration Options – Check for digital/analog output compatibility with IoT systems.

Future Trends in Electrochemical HCHO Sensors

- Miniaturization – Development of ultra-compact sensors for wearables.

- IoT & Cloud Connectivity – Integration with smart home and industrial IoT platforms.

- Multi-Gas Detection – Hybrid electrochemical sensors capable of detecting multiple VOCs simultaneously.

- AI-driven Calibration – Machine learning algorithms for self-calibrating sensors.

FAQs on Electrochemical HCHO Sensors

Q1: How accurate are electrochemical HCHO sensors?

They can detect formaldehyde concentrations down to ppb levels with high reliability.

Q2: Do they need regular calibration?

Yes, calibration every 6–12 months ensures precise measurements.

Q3: Can they detect other VOCs?

They are highly selective, but some designs may still show minor cross-sensitivity.

Q4: How long do these sensors last?

Typically between 24–36 months, depending on usage.

Q5: Where are they most commonly used?

In air quality monitors, industrial safety equipment, laboratories, and IoT-enabled devices.

Conclusion

Electrochemical HCHO sensors are among the most reliable and accurate solutions for monitoring formaldehyde in homes, workplaces, and industrial environments. They combine high sensitivity, selectivity, and low power consumption, making them ideal for both professional safety equipment and consumer air quality devices.

As demand for indoor air quality monitoring continues to rise, electrochemical HCHO sensors will play a critical role in protecting human health and supporting regulatory compliance.