NH₃ Sensor: Working Principle, Applications, and Benefits

Introduction

Ammonia (NH₃) sensors are specialized gas detection devices designed to measure the concentration of ammonia in the air or within industrial processes. Ammonia is widely used in industries such as refrigeration, agriculture, fertilizer production, and chemical manufacturing. While essential for many applications, ammonia can be hazardous at high concentrations—causing irritation, respiratory problems, and even life-threatening conditions.

To ensure workplace safety, environmental monitoring, and process efficiency, ammonia sensors play a vital role. They allow real-time detection of ammonia leaks, help comply with occupational safety standards, and protect people and assets.

This article explores the principle of NH₃ sensors, their types, applications, installation considerations, and future outlook.

What Is Ammonia (NH₃)?

Ammonia is a colorless gas with a pungent odor, commonly recognized in household cleaners and industrial processes.

- Chemical formula: NH₃

- Molecular weight: 17.03 g/mol

- Boiling point: -33.34 °C

- Hazard classification: Corrosive, toxic at high levels

Ammonia is commonly used as:

- A refrigerant (R-717) in large-scale refrigeration systems.

- A raw material for fertilizers and chemicals.

- A cleaning agent and neutralizer in various industries.

Because of its toxicity, ammonia must be carefully monitored, making NH₃ sensors indispensable.

Why NH₃ Detection Is Important

1. Worker Safety

- Exposure to 25 ppm or higher can cause irritation.

- Prolonged exposure can damage lungs and eyes.

- OSHA and ACGIH regulate workplace ammonia exposure limits.

2. Environmental Compliance

- Ammonia emissions contribute to air pollution and eutrophication.

- Monitoring ensures compliance with environmental standards.

3. Equipment Protection

- In refrigeration systems, ammonia leaks can damage compressors, pipes, and valves.

- Early detection prevents costly breakdowns.

4. Process Efficiency

- Accurate detection improves fertilizer production and chemical processes.

Working Principle of NH₃ Sensors

NH₃ sensors operate on different detection principles, depending on the sensing technology:

1. Electrochemical Sensors

- Use a chemical reaction between ammonia and an electrode.

- Produce an electrical current proportional to NH₃ concentration.

- Advantages: High sensitivity, low detection limits, stable.

- Applications: Industrial safety, portable detectors.

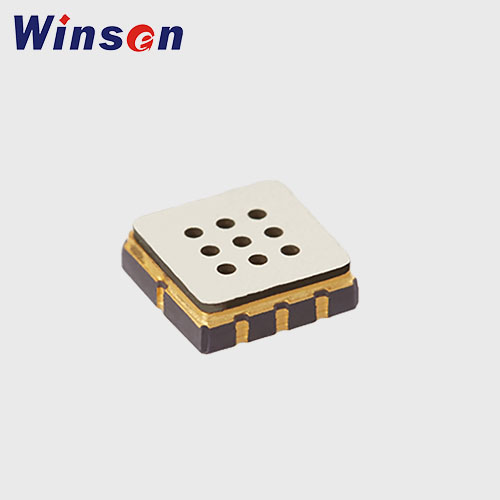

2. Semiconductor (MOS) Sensors

- Rely on a metal oxide surface that changes resistance when exposed to NH₃.

- Advantages: Low cost, fast response.

- Limitations: Cross-sensitivity to other gases, humidity influence.

3. Optical Sensors

- Use absorption of light at specific wavelengths for ammonia detection.

- Can be based on NDIR (non-dispersive infrared) or laser spectroscopy.

- Advantages: Highly selective, suitable for continuous monitoring.

4. Catalytic Sensors

- Use a catalyst-coated element that reacts with ammonia at elevated temperatures.

- Generate a change in resistance or heat, indicating ammonia concentration.

Applications of NH₃ Sensors

1. Refrigeration Systems (R-717)

- Large cold storage facilities use ammonia as a refrigerant.

- NH₃ sensors detect leaks, ensuring safety and compliance with ASHRAE standards.

2. Agriculture & Fertilizer Industry

- Ammonia-based fertilizers (urea, ammonium nitrate) require monitoring during production and storage.

- Prevents accidental exposure in fertilizer plants.

3. Industrial Safety Monitoring

- Chemical plants, wastewater treatment, and food processing facilities use NH₃ sensors to prevent accidents.

4. Environmental Monitoring

- Track ammonia emissions from livestock farms, sewage plants, and industrial sites.

- Supports regulatory reporting and pollution reduction.

5. Medical & Research Applications

- NH₃ sensors can measure ammonia in human breath, useful for diagnosing liver and metabolic conditions.

Installation and Calibration Considerations

Installation Guidelines

- Install NH₃ sensors close to potential leak points such as valves, compressors, and storage tanks.

- Place sensors at higher levels, since ammonia is lighter than air and tends to rise.

- Use redundant sensors in large facilities for accurate monitoring.

Calibration

- Regular calibration is critical to ensure accuracy.

- Use standard calibration gases (ammonia-air mixtures).

- Frequency depends on the sensor type (electrochemical sensors may require calibration every 6–12 months).

Advantages of NH₃ Sensors

- High sensitivity to detect even trace levels of ammonia.

- Fast response to leaks for early warning.

- Compact and versatile for portable, fixed, or integrated systems.

- Wide operating range, suitable for harsh environments.

- Cost-effective prevention of accidents and downtime.

Challenges and Limitations

- Cross-sensitivity: Some sensors respond to other gases like H₂S or CO.

- Humidity and temperature effects can alter sensor performance.

- Maintenance requirements: Regular calibration and replacement needed.

- Sensor poisoning: Exposure to certain chemicals may degrade performance.

NH₃ Sensor Technologies Comparison

| Technology | Sensitivity | Selectivity | Cost | Applications |

|---|---|---|---|---|

| Electrochemical | High | Good | Medium | Industrial, portable |

| MOS (Semiconductor) | Medium | Moderate | Low | HVAC, refrigeration |

| Optical | Very High | Excellent | High | Research, environment |

| Catalytic | Medium | Low | Low | Safety alarms |

Future of NH₃ Sensing

The demand for ammonia sensors is expected to grow due to:

- Green Ammonia Projects: Ammonia as a hydrogen carrier for clean energy.

- Stricter Regulations: Tighter emission and workplace safety standards.

- Advances in Nanotechnology: Development of nanomaterial-based NH₃ sensors for higher sensitivity and stability.

- Integration with IoT: Smart, wireless NH₃ sensors for real-time monitoring and predictive maintenance.

FAQs About NH₃ Sensors

Q1: What is the typical detection range of an ammonia sensor?

Most industrial NH₃ sensors detect concentrations from 0–100 ppm, with some extending up to 1,000 ppm.

Q2: Where should NH₃ sensors be installed in a facility?

They should be placed near potential leak sources and at ceiling level, since ammonia rises in air.

Q3: How often should NH₃ sensors be calibrated?

Electrochemical sensors typically require calibration every 6–12 months, while optical sensors may need less frequent calibration.

Q4: Are NH₃ sensors safe for medical use?

Yes, certain optical and electrochemical NH₃ sensors are used in medical diagnostics, such as breath analysis.

Q5: Can NH₃ sensors work in high-humidity environments?

Yes, but performance can be affected; selecting sensors with humidity compensation is recommended.

Conclusion

NH₃ sensors are essential safety and monitoring tools across refrigeration, agriculture, environmental, and industrial applications. By detecting ammonia leaks early, they help protect workers, safeguard equipment, and ensure regulatory compliance.

With advancements in sensor technology, especially in nanomaterials, IoT integration, and optical detection, the next generation of NH₃ sensors will offer even greater accuracy, reliability, and connectivity.

For industries that rely on ammonia, investing in high-quality NH₃ detection systems is not just about safety—it is also about sustainability and efficiency.