MOS (Semiconductor) Hydrogen Sensors: Principles, Advantages, and Applications

Hydrogen (H₂) is a widely used industrial gas with growing importance in clean energy technologies such as fuel cells and hydrogen combustion. However, hydrogen is highly flammable and invisible to the human senses, making reliable leak detection essential for safety. One of the most promising technologies for detecting hydrogen gas is the Metal Oxide Semiconductor (MOS) sensor. In this comprehensive guide, we explore the working principles, features, advantages, limitations, and applications of MOS hydrogen sensors.

What Is a MOS Hydrogen Sensor?

![]()

A MOS hydrogen sensor is a type of gas sensor that uses a metal oxide material, typically tin dioxide (SnO₂), zinc oxide (ZnO), or tungsten trioxide (WO₃), to detect hydrogen gas through changes in electrical conductivity. When hydrogen interacts with the sensor's surface, it alters the resistance of the sensing material, which is then measured and interpreted as a gas concentration.

These sensors belong to a broader class of semiconductor gas sensors, known for their simplicity, low cost, and good sensitivity to reducing gases like H₂.

Working Principle of MOS Hydrogen Sensors

1. Baseline Resistance

In ambient air, oxygen molecules are adsorbed on the metal oxide surface and trap free electrons from the conduction band, forming O⁻ or O²⁻ ions. This creates a depletion layer and increases the material's resistance.

2. Hydrogen Interaction

When hydrogen gas comes into contact with the sensor:

- Hydrogen molecules (H₂) react with the adsorbed oxygen species.

- The reaction releases the trapped electrons back into the conduction band.

- This reduces the width of the depletion layer and decreases the sensor's resistance.

3. Signal Output

The drop in resistance is proportional to the hydrogen concentration. The sensor electronics convert this change into a voltage or digital signal.

Key Features of MOS Hydrogen Sensors

| Feature | Description |

|---|---|

| Gas Type | Hydrogen (H₂) |

| Sensing Principle | Change in electrical resistance |

| Sensor Material | Metal oxides (SnO₂, ZnO, WO₃) |

| Detection Range | ~1 ppm to 1000 ppm (varies by design) |

| Response Time | Fast (seconds to minutes) |

| Operating Temp | 100°C to 400°C |

| Power Consumption | Low to moderate |

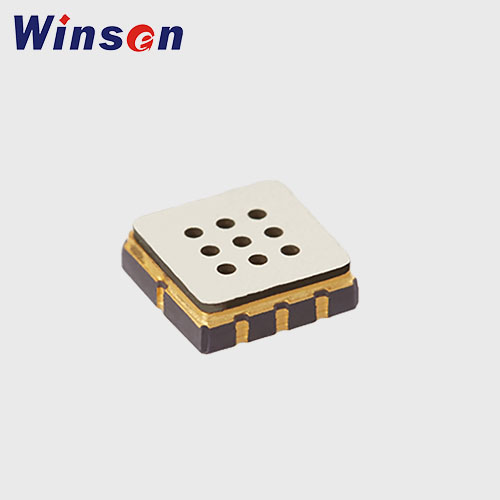

| Size | Compact, SMD or TO packages |

Advantages of MOS Hydrogen Sensors

High Sensitivity

Can detect low concentrations of hydrogen, often in the ppm range.Fast Response and Recovery

Typical response times are under 30 seconds for hydrogen leaks.Low Cost

Inexpensive materials and scalable manufacturing make these sensors ideal for mass-market applications.Compact Design

Ideal for integration into portable and embedded devices.Stability

Long-term stable operation with minimal drift when used correctly.Compatibility with Microcontrollers

Analog output makes it easy to integrate into IoT and embedded systems.

Limitations of MOS Hydrogen Sensors

Selectivity Issues

MOS sensors are sensitive to many reducing gases (e.g., methane, ethanol, carbon monoxide), which may lead to false positives.Humidity Interference

High humidity can affect adsorption reactions and sensor accuracy.Temperature Dependence

Requires elevated temperatures (often >200°C) to operate correctly.Power Requirements

Heating elements consume more power than electrochemical or catalytic sensors.Aging and Drift

Sensor performance can degrade over time due to contamination or material fatigue.

Comparison with Other Hydrogen Sensor Technologies

| Feature | MOS Sensor | Electrochemical Sensor | Catalytic Bead Sensor |

|---|---|---|---|

| Operating Temp | High (150–400°C) | Room temp | High (~500°C) |

| Selectivity | Moderate | High | Low |

| Sensitivity | Good | Very good | Moderate |

| Lifetime | Medium (1–3 years) | Medium (2–3 years) | High |

| Power Consumption | Moderate | Low | High |

| Cost | Low | Moderate | Low |

| Explosion Risk | Low | Very low | Moderate (heater element) |

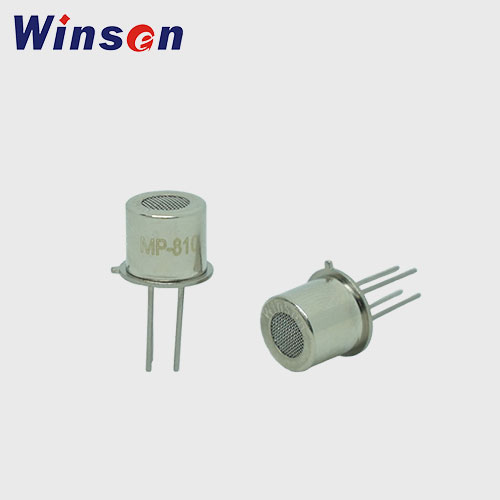

Sensor Construction

A typical MOS hydrogen sensor includes:

- Sensing Layer: A metal oxide film deposited on a ceramic substrate.

- Heater Element: Provides the required temperature for gas interaction.

- Electrodes: Measure changes in conductivity across the sensing layer.

- Package: Usually ceramic, TO-type, or SMD format with a gas-permeable cap.

In advanced versions, nanostructured materials like nanowires or nanoparticles enhance sensitivity and reduce response time.

Calibration and Testing

MOS hydrogen sensors must be calibrated for accurate performance. Calibration involves:

- Exposing the sensor to a known hydrogen concentration.

- Measuring baseline resistance in clean air.

- Creating a calibration curve (Resistance vs. H₂ concentration).

- Periodic recalibration to compensate for drift and aging.

Applications of MOS Hydrogen Sensors

1. Hydrogen Fuel Cells

- Leak detection in vehicles and hydrogen storage systems.

- Safety sensors in hydrogen refueling stations.

2. Industrial Safety

- Monitoring H₂ in chemical plants, battery rooms, and welding applications.

- Portable hydrogen leak detectors.

3. Consumer Electronics

- Integrated sensors in wearable or home safety devices.

- Hydrogen detection in research labs and educational kits.

4. Environmental Monitoring

- Detecting H₂ as a marker for geological activity or industrial emissions.

5. Medical Applications

- Breath analysis for gastrointestinal diagnostics (e.g., lactose intolerance).

Safety and Handling

MOS hydrogen sensors are non-toxic and intrinsically safe when used correctly. However, follow these guidelines:

- Ensure proper ventilation during testing.

- Avoid exposure to siloxanes, sulfur compounds, or silicone vapors, which can poison the sensor.

- Use temperature compensation for accurate readings under varying ambient conditions.

Innovations and Future Trends

Nanotechnology Enhancements

Use of nanowires, nanotubes, and porous structures increases the active surface area, improving detection limits and response times.

Integrated Smart Sensors

MOS hydrogen sensors are being integrated with microcontrollers and wireless modules for real-time data transmission in IoT ecosystems.

Hybrid Sensor Systems

Combining MOS with optical or electrochemical elements to improve selectivity and reduce false alarms.

Winsen Semiconductor Hydrogen Sensors

Frequently Asked Questions (FAQs)

What gases interfere with MOS hydrogen sensors?

Reducing gases such as methane, ethanol, propane, and carbon monoxide can interfere with readings.

Can MOS sensors be used in outdoor environments?

Yes, but they require protective housing and environmental compensation (humidity and temperature).

How long do MOS hydrogen sensors last?

Typically 1–3 years under regular use, depending on the environment and exposure to contaminants.

Do they require recalibration?

Yes, periodic recalibration is recommended to ensure accuracy, especially in critical applications.

Conclusion

MOS hydrogen sensors offer a compelling combination of affordability, fast response, and simplicity, making them ideal for many hydrogen monitoring applications. While they have limitations in selectivity and environmental sensitivity, ongoing research in nanomaterials and smart electronics is helping to overcome these challenges.

Whether you are developing hydrogen-powered systems, industrial safety tools, or environmental monitors, MOS sensors represent a robust and scalable solution for detecting hydrogen safely and reliably.