Electrochemical O₃ Sensor — Working Principle, Specifications, Selection, and Integration (Winsen OEM Guide)

1) What Is an Electrochemical Ozone Sensor?

An electrochemical (EC) ozone sensor converts O₃ concentration into a tiny electrical current through a controlled redox reaction at a catalytic electrode. Because the current is proportional to the partial pressure of ozone, EC sensors deliver high sensitivity (ppb–ppm), good linearity, low power, and compact size, making them ideal for fixed transmitters, portable/wearable monitors, and closed-loop control.

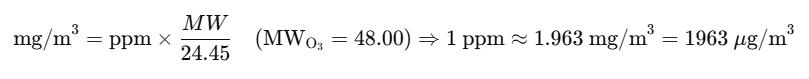

Typical reporting units: ppb or ppm by volume, and µg/m³ or mg/m³ by mass.

Quick conversion at 25 °C, 1 atm:

2) How EC Ozone Sensors Work (In Plain but Precise Terms)

- Diffusion: O₃ diffuses through a gas-permeable membrane into the electrochemical cell.

- Electrode reaction: At the working electrode, ozone is typically reduced to O₂ in the presence of electrolyte and catalyst.

- Charge transfer: The redox reaction generates a microamp-level current proportional to O₃ concentration.

- Reference/counter electrodes: Stabilize potential and close the circuit to maintain linear response.

- Signal conditioning: Low-noise electronics convert microamps to a scaled voltage/digital output, with temperature & humidity compensation.

Why EC for O₃?

- Real ppb–ppm sensitivity without optical benches or UV lamps

- Stable baseline and linear span over common IAQ/industrial ranges

- Small, low-power modules suitable for battery devices and multi-sensor platforms

3) Winsen Electrochemical O₃ Lineup (Modules & Raw Cells)

The models below are electrochemical. Choose modules for fastest time-to-market, or raw cells when you already have analog front-end and firmware.

3.1 EC Modules (with onboard conditioning & digital I/O)

| Model | Measuring Range | Resolution | Output/Interface | Size & Power | Best Fit |

|---|---|---|---|---|---|

| ZE25A-O3 | 0–2 ppm | 0.001 ppm | UART (3.3–5 V) | Mini, low power | IAQ nodes, wearables needing ppb-class display |

| ZE25-O3 | 0–10 ppm | 0.01 ppm | UART + Analog (≈0.4–2.0 V) | Compact, temp-comp | BMS/PLC where a voltage channel is required |

| ZE27-O3 | 0–10 ppm | 0.01 ppm | UART (3 V-TTL) | Ultra-mini footprint | Tight enclosures, personal/portable safety |

| ZE14-O3 | 0–100 ppm | 0.1 ppm | UART (5 V) | Robust, wider span | Disinfection cabinets/rooms, post-treatment decay |

| ZE03 + EC O₃ cell | per cell | per cell | UART + Analog | Universal module platform | Instruments supporting multiple toxic gases |

Shared module features (typical): temperature/humidity compensation, factory alignment, UART protocol (framing + checksum), simple 4-pin or 5-pin header integration, optional alarm mapping via host MCU.

EC Hazardous Toxic Gas Detection Sensor Module ZE03

- CO,O2,NH3,H2S,NO2,O3,SO2, CL2,HF,H2,PH3,HCL, etc.

- See manual

- Read More

3.2 EC Raw Cells (for instrument makers)

| Model | Nominal Range Options | Typical Sensitivity | T90 (typ.) | Notes |

|---|---|---|---|---|

| ME3-O3 | 0–10/20 ppm (max 50–100 ppm) | ~1.0–1.2 µA/ppm | ≤ 120 s | Stable cell for fixed/portable analyzers |

| ME2-O3 | 0–10/100 ppm (max up to 200 ppm) | model-dependent | ≤ 120 s | Robust “fuel-cell” style; multiple ranges |

| ME2-O3-16×15 | 0–10/100 ppm | model-dependent | ≤ 120 s | Compact package, easy board-mount |

When to pick a raw cell: You need full control of the analog front-end (transimpedance amplifier, filtering), compensation algorithms, certification pathway, and mechanical packaging.

4) Performance You Should Specify (and Why It Matters)

- Range & Resolution: Match to risk. For IAQ and personnel safety, 0–2 or 0–10 ppm with resolution 1–10 ppb is typical. For disinfection processes, 0–100 ppm avoids clipping.

- Accuracy/Linearity: State as ±(% of reading + offset) under a given T/RH window (e.g., ±(5 %rdg + 5 ppb) at 23 °C/50 %RH).

- Response (T90/T10): EC modules typically ≤ 90 s step response; raw cells ≤ 120 s. Faster dynamics require pumped sampling and short tubing.

- Drift: Specify zero and span drift per month at nominal conditions; schedule maintenance accordingly.

- Environmental window: Operating −20…+50 °C and 15–95 %RH (non-condensing) are common; confirm your exact envelope.

- Power & interface: Modules run at 3.3–5 V with UART (and sometimes analog). For PLCs, select a transmitter or add 4–20 mA conversion.

5) Cross-Sensitivity & Interference Control

Electrochemical O₃ cells are selective, but oxidizing gases can interfere:

- NO₂, Cl₂: Often positive cross-response (over-reporting).

- SO₂, H₂S: Negative/poisoning effects possible at higher levels.

- Humidity/Temperature swings: Baseline and sensitivity shift without compensation.

Mitigation strategies:

- Selectivity filters / scrubbers on the inlet (for Cl₂/NO₂).

- Dual-channel compensation (pair O₃ with NO₂ and subtract modeled interference).

- Onboard T/RH compensation, hydrophobic membranes, and algorithmic smoothing (moving average + rate-of-rise gate).

6) Mechanical Design & Materials

-

Ozone-compatible wetted parts: PTFE, FEP, PFA, PVDF, glass, 316L; avoid natural rubber and standard PVC.

-

Sampling method:

- Diffusion → lowest power and simplest build (great for IAQ/safety nodes).

- Pumped → faster response, longer sample lines; add particulate filter + condensate trap.

-

Placement: Representative airflow, away from direct UV lamps that can photolyze O₃ locally; shield from splashes and dust (IP65–IP67 housings).

-

Thermal design: Prevent condensation; provide small vents/breathers and drip loops; avoid heat sources that outgas.

7) Electrical & Firmware Integration

- Analog front-end (raw cells): Low-noise TIA (transimpedance amplifier), guard rings, high-value feedback resistors with low leakage, and RC anti-alias filtering.

- Modules: Read UART frames (concentration + status); for ZE25-O3, map 0.4–2.0 V to span (linear).

- Compensation: Apply temperature/humidity compensation; store calibration constants and health flags (sensor age, zero offset, span factor).

- Filtering & alarms: 1–5 s moving average, hysteresis, minimum on-time for relays/fans, optional rate-of-rise trigger for spill events.

- Diagnostics: Track baseline noise, recovery time after exposure, and days-in-service for predictive maintenance.

8) Calibration, Bump Tests, and QA

- Zero: Ozone-scrubbed air (activated carbon, MnO₂, or catalytic scrubbers) or certified zero air.

- Span: Photometric ozone generator/transfer standard or a certified source; define flow, exposure time, and stabilization.

- Intervals: Bump tests weekly–monthly (risk-based). Full calibration every 3–6 months for EC; verify after major environmental changes.

- Documentation: Record as-found/as-left, span value, temperature, RH, barometric pressure, and serial numbers to support ISO 9001/14001 and EHS audits.

9) Model-to-Application Selection Guide

| Scenario | Recommended EC Model | Rationale |

|---|---|---|

| Office/School IAQ, generator by-product check | ZE25A-O3 (0–2 ppm) or ZE25-O3 (0–10 ppm) | Calibrated, compact, UART (and analog on ZE25-O3) for BMS integration |

| Disinfection room/cabinet, post-treatment decay | ZE14-O3 (0–100 ppm) | Wide span avoids saturation; robust EC linearity for control & safety |

| Wearable/portable safety | ZE27-O3 | Ultra-mini footprint and low power for body-worn nodes |

| Custom instruments with your own AFE | ME2-O3 / ME3-O3 / ME2-O3-16×15 | Direct cell integration, full control of electronics & algorithm |

| Multi-gas modular platform | ZE03 + EC O₃ cell | Same motherboard across toxics; mix-and-match for SKU families |

10) Typical Specifications (Reference Values)

Use these as ordering guidance; Winsen provides model-specific datasheets.

- Resolution: 1 ppb–0.1 ppm depending on model and range

- T90 response: ≤ 90 s (modules), ≤ 120 s (raw cells)

- Accuracy (23 °C/50 %RH): ±(5 %rdg + 5–10 ppb) typical after calibration

- Operating: −20…+50 °C, 15–95 %RH non-condensing

- Interfaces: UART (3.3–5 V); some modules also provide 0.4–2.0 V analog or are readily adapted to 4–20 mA/RS-485 transmitters

- Power: Tens of mW (modules) in steady sampling; raw cells draw no power (electronics only)

11) Installation & Commissioning Checklist

- Confirm range & alarm thresholds (warning/action) with hysteresis.

- Mount in representative airflow; avoid UV lamp line-of-sight.

- Use ozone-resistant tubing/filters; add condensate trap if pumped.

- Log T/RH and enable compensation; allow warm-up (≥ 2–3 min).

- Zero with scrubbed air, then span at target level; record as-found/as-left.

- Validate alarm behavior (latching, delay, minimum on-time).

- Store RFQ & calibration metadata: range, offsets, span factor, date, technician.

- Schedule bump tests and periodic full calibration.

12) FAQs

Q1. Why choose EC over MOS or UV photometric?

EC gives ppb–ppm sensitivity with low power and small size. UV photometric is reference-grade but larger/more power; MOS is economical for trends but less selective and needs stronger algorithms.

Q2. How do I handle NO₂/Cl₂ interference?

Use inlet filters/scrubbers, pair with a NO₂ channel for algorithmic subtraction, and maintain clean, dry sampling to stabilize baselines.

Q3. Can I run long sample lines?

Yes, with pumped sampling. Keep lines short and straight, use PTFE/PFA, and add particulate + moisture management.

Q4. How often should I calibrate?

Perform risk-based bump tests (weekly–monthly) and full calibration every 3–6 months or after major environmental changes.

Q5. Which module for 0–10 ppm with both digital and analog?

ZE25-O3 (UART + 0.4–2.0 V analog) is purpose-built for that need.

13) Why Winsen for Electrochemical O₃

- Complete EC portfolio: Plug-and-play ZE-series modules and ME-series raw cells for OEM flexibility.

- Fast integration: UART/analog outputs, temperature compensation, compact footprints, clear protocols.

- Scalable manufacturing & QA: Batch consistency, outgoing tests, and calibration guidance.

- Customization: Ranges, connectors, housings, selective filters, and firmware adaptations for volume programs.

Talk to Our Engineers

Share your range, form factor, interface, environment, and certification needs. We’ll recommend the optimal ZE/ME electrochemical O₃ solution, provide evaluation kits, and help you accelerate certification and time-to-market.