O₃ Sensor (Ozone Sensor) — Principles, Specifications, Applications, and Integration Guide

What Is an Ozone (O₃) Sensor?

An O₃ sensor measures the concentration of ozone, a reactive oxidizing gas used for disinfection, odor control, and water treatment, but harmful to humans and materials at elevated levels. Accurate measurement is essential to protect workers, maintain indoor air quality (IAQ), verify disinfection cycles, and support regulatory reporting for ambient monitoring.

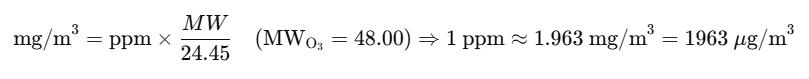

Typical reporting units: ppb/ppm (by volume) and µg/m³ (mass concentration).

At 25 °C and 1 atm:

Sensing Technologies at a Glance

| Technology | Core Principle | Typical Range & LOD | Response (T90) | Selectivity | O&M | Best For |

|---|---|---|---|---|---|---|

| Electrochemical (EC) | O₃ undergoes redox at a catalytic electrode; current ∝ concentration | 0–1/5/10 ppm; LOD 1–10 ppb | 20–60 s | High for O₃; some cross-sensitivities (e.g., Cl₂, NO₂, SO₂) | Low–medium (calibration, filter changes) | Personal/fixed safety, IAQ, process areas |

| UV Photometric (Absorption at 254 nm) | Lambert–Beer absorption in a gas cell using a low-pressure Hg or UV-LED source | 0–500 ppb to 0–1 ppm; LOD ~1 ppb | 10–60 s | Reference-grade specificity to O₃ | Medium (optics cleanliness) | Regulatory/ambient monitoring, reference points |

| MOS (Semiconductor) | O₃ oxidizes sensor surface, changing conductivity | 0–1 ppm; LOD tens of ppb | 10–60 s | Broader cross-sensitivity; requires T/RH compensation | Low | Low-cost IAQ, trend detection |

| Electrochemical + Filtered Inlet | EC with scrubbers/filters to knock down interferences | 0–1/5 ppm; LOD ppb | 20–60 s | Improved selectivity vs EC alone | Medium (filter service) | Industrial/HVAC safety, disinfection rooms |

Winsen Electrochemical O3 Sensor

EC Hazardous Toxic Gas Detection Sensor Module ZE03

- CO,O2,NH3,H2S,NO2,O3,SO2, CL2,HF,H2,PH3,HCL, etc.

- See manual

- Read More

Winsen Semiconductor O3 Sensor

Rule of thumb

- Choose Electrochemical for compact, low-power, ppb–ppm detection in personal/fixed monitors.

- Choose UV photometric for reference-grade ambient monitoring or when you need high linearity and compound specificity.

- Choose MOS for cost-sensitive IAQ or event trending where modest accuracy is acceptable.

How the Main Technologies Work

Electrochemical (EC) O₃ Sensors

- Mechanism: Ozone diffuses through a gas-permeable membrane to a working electrode; it is reduced (or oxidized, depending on design). The generated current (µA) is proportional to concentration.

- Strengths: High sensitivity (ppb), low power, compact, simple interface (analog/µA or conditioned voltage).

- Considerations: Cross-sensitivity to oxidizers (Cl₂, NO₂) and acid gases (SO₂ negative/positive response depending on catalyst). Humidity/temperature affect zero and slope; compensation and integrated T/RH sensing recommended.

UV Photometric O₃ Analyzers

- Mechanism: Measures O₃ absorption at ~254 nm; some designs alternate with an O₃ scrubber to obtain zero/reference.

- Strengths: High specificity, excellent linearity and stability; favored for standards-compliant measurements.

- Considerations: Larger footprint, higher power, periodic lamp/LED and optics maintenance, pump/flow control.

MOS O₃ Sensors

- Mechanism: Ozone’s strong oxidizing nature modulates the conductivity of a metal oxide film.

- Strengths: Low cost, small form factor.

- Considerations: Requires strong algorithmic compensation; susceptible to long-term drift and cross-gas effects; use for relative trends or IAQ scoring more than absolute compliance.

Winsen O₃ Sensing Portfolio at a Glance

Winsen offers electrochemical (EC), semiconductor/MOS, and ready-to-use modules that balance ppb-level sensitivity, wide ranges, small size, and low power.

| Model | Tech | Range | Resolution | Interface | Notable features / Notes |

|---|---|---|---|---|---|

| ZE25A-O3 | EC module | 0–2 ppm | 0.001 ppm | UART (3 V) | Mini module for IAQ & portable devices; T90 ≤ 90 s; 3.7–5.5 V. |

| ZE25-O3 | EC module | 0–10 ppm | 0.01 ppm | UART + Analog (0.4–2 V) | Temp compensation, excellent linearity; 23×25.5×4.4 mm. |

| ZE27-O3 | EC module | 0–10 ppm | 0.01 ppm | UART (3 V-TTL) | Ultra-mini (≈ 17.1×19.2×4.5 mm), very low power. |

| ZE14-O3 | EC module | 0–100 ppm | 0.1 ppm | UART (5 V) | Extended range for disinfection cabinets & process areas. |

| ZE03 + O₃ cell | EC module platform | per sensor | — | UART + Analog | Universal EC module body supporting O₃ and other toxic gases. |

| ME3-O3 | EC cell | 0–10/20 ppm (max 50/100 ppm) | 0.05 ppm | Raw cell | Industrial/EP monitoring; Sensitivity ~1.2 µA/ppm; T90 ≤ 120 s. |

| ME2-O3 | EC cell | 0–10/100 ppm (max 200 ppm) | ≤ 0.02 ppm | Raw cell | Robust fuel-cell type; repeatability ≤ 5 %. |

| ME2-O3-16×15 | EC cell | 0–10/100 ppm (max 200 ppm) | ≤ 0.02 ppm | Raw cell | Compact package (16×15×6.2 mm); T90 ≤ 120 s. |

| ZQ02-O3 | MOS module | 10–1000 ppb | 10 ppb | Digital output + buzzer | Mini, < 30 s response, 5-year lifespan; ideal for home alarms. |

| MQ131-L | MOS sensor | 10–1000 ppb | — | Resistive | Low-concentration ppb-level IAQ/alarms; heater 5 V. |

| MQ131-H | MOS sensor | 10–1000 ppm | — | Resistive | High-concentration ppm applications; heater 5 V. |

Application Playbooks

1) Disinfection Rooms, Cold Storage, and Food Processing

- Goal: Verify post-treatment decay to safe re-entry; interlock ventilation.

- Sensor: EC O₃ with ppb–ppm range, fast T90; add audible/visual alarms.

- Tips: Use ozone-resistant tubing, place sensor near breathing zone height, and enable high-RH compensation.

2) HVAC & IAQ in Offices, Schools, Healthcare

- Goal: Monitor byproducts from in-duct ozone generators or building infiltration from outside smog.

- Sensor: EC (compact) or MOS (trend/threshold).

- Tips: Integrate with BMS (Modbus/4–20 mA); set ventilation overrides upon exceedance.

3) Ambient Air Monitoring & Research

- Goal: Long-term, accurate ppb-level trends for compliance/research.

- Sensor: UV photometric with temperature-controlled cell and auto-zero via internal scrubber.

- Tips: Maintain flow control and schedule lamp/optics cleaning; co-locate with reference stations for audits.

4) Worker Exposure & Confined Spaces

- Goal: Personal exposure screening near O₃ equipment or after maintenance.

- Sensor: Wearable EC with data logging and bump test routine.

- Tips: Train for filter changes and fresh-air zeroing; verify alarm sounder/latch behavior.

Installation Best Practices

- Location: Representative airflow; avoid UV lamps or strong oxidizers upstream of the sensor without accounting for decay.

- Ingress & sealing: Choose IP65–IP67 housings for washdown/industrial; include drip loops and breathers to reduce condensation.

- Serviceability: Provide front-accessible filters and a calibration port; label gas path direction.

- Materials: Use PTFE/PFA/PVDF/316L wetted parts; avoid natural rubber and standard PVC in high-O₃ areas.

- Electrical: Separate sensor wiring from VFD/motor cables; add TVS for surge; bond shields at single point.

FAQs

Q1. How low can an EC O₃ sensor measure?

A: With proper conditioning and averaging, single-digit ppb is achievable. Specify required LOD and averaging time.

Q2. Why does my O₃ reading change with humidity?

A: Water vapor affects electrochemistry and membrane diffusion. Use T/RH compensation, hydrophobic barriers, and avoid condensation.

Q3. Can I measure O₃ with long sample tubing?

A: Yes, but O₃ decays on reactive surfaces. Use short PTFE/PFA lines, minimize bends, and keep flow steady.

Q4. My site also has NO₂ and Cl₂. Will they interfere?

A: They can. Use selective filters, paired NO₂ measurement for compensation, or a UV photometric approach for high selectivity.

Q5. How often should I calibrate?

A: Perform bump tests weekly–monthly based on risk; full calibration every 3–6 months (EC). UV photometric analyzers follow instrument QA schedules.

Q6. Can MOS sensors be used for safety alarms?

A: MOS is best for trend/IAQ applications. For safety-critical alarms, prefer EC or UV photometric with proper calibration.

Q7. Does activated carbon remove ozone?

A: Yes—activated carbon and catalytic scrubbers are effective and commonly used for zeroing and post-disinfection decay control.

Q8: Which model is best for a compact IAQ node with ppb-class sensitivity?

A: ZE25A-O3 (0–2 ppm, 0.001 ppm resolution, UART) balances sensitivity and size.

Q9: I need both UART and analog voltage.

A: ZE25-O3 offers UART and 0.4–2 V analog mapping to 0–10 ppm.

Q10: What if my process peaks near tens of ppm?

A: Use ZE14-O3 (0–100 ppm) or ME-series raw cells with appropriate conditioning.

Q11: Do you have a tiny, low-power module for wearables?

A: ZE27-O3 is extremely compact (≈ 17.1×19.2×4.5 mm).

Q12: Any off-the-shelf module for household O₃ alarms?

A: ZQ02-O3 integrates a MOS sensor, buzzer, and alarm logic (10–1000 ppb, < 30 s response).

Why Choose Winsen

- Complete portfolio: EC O₃ modules, MOS options, and RS-485/4–20 mA transmitters.

- Engineering depth: Temperature/humidity compensation, cross-gas mitigation strategies, and integration libraries (UART/I²C/Modbus).

- Manufacturing & QA: Batch consistency, traceable calibration, global logistics.

- Customization: Form factors, ranges, filters, housings, and accessories tailored to OEM needs.

Talk to Our Engineers

Designing an ozone monitor for safety, IAQ, ambient compliance, or disinfection control? Contact Winsen with your range, interface, environment, and calibration needs. We’ll propose the optimal EC / UV photometric / MOS solution, provide evaluation kits, and accelerate your time-to-market.