VOC Sensor (Volatile Organic Compounds Sensor) — Principles, Types, Specifications, and Integration Guide

1) What Are VOCs and TVOC?

VOCs (Volatile Organic Compounds) are a broad class of carbon-based chemicals that readily evaporate at room temperature. Typical examples include toluene, xylene, benzene, ethanol, isopropyl alcohol, acetone, formaldehyde, ethyl acetate, and styrene.

TVOC (Total VOC) is a cumulative indicator that sums multiple VOCs over a defined carbon range (commonly C6–C16 for IAQ assessments). TVOC is widely used to evaluate overall air freshness, odor, and potential health impact in indoor environments and to guide ventilation/filtration strategies.

Why measure VOCs?

- Health & comfort: Helps mitigate headaches, irritation, fatigue, and odor complaints.

- Compliance & ESG: Supports documentation for emissions control, green building, and solvent use management.

- Process quality: VOC level correlates with curing, coating, printing, and adhesive processes.

- Energy optimization: Enables demand-controlled ventilation and targeted abatement.

2) Sensing Technologies at a Glance

Different applications benefit from different sensing principles. Below is a practical comparison.

| Technology | Core Principle | Typical Range | Resolution | Selectivity | Warm-up | Lifetime | O&M / Cost | Best For |

|---|---|---|---|---|---|---|---|---|

| MOS / MEMS (Metal-Oxide Semiconductor) | Surface chemisorption changes film conductivity; reported as equivalent ethanol/IAQ index or resistance | 0–10 ppm (IAQ) up to 0–50 ppm (some types) | 1–10 ppb (IAQ-class) | Broad response to many VOCs; cross-sensitive to H₂, CO, humidity | 1–3 min | 5–10 yrs | Low | IAQ monitors, smart thermostats, wearables, consumer/white goods |

| PID (Photoionization Detector) | UV lamp (e.g., 10.6 eV) ionizes VOCs; ions measured as current | 0–2,000 ppm (model-dependent), ppb-level detection | <1 ppb possible | Very broad; response depends on ionization potentials; water/isobutylene factors apply | Seconds | Lamp: 6–18 months typical | Medium–High (lamp upkeep) | Industrial hygiene, leak checks, fast response surveys |

| NDIR / PAS (infrared / photoacoustic) | IR absorption at specific wavelengths; PAS for higher sensitivity | Target-specific (e.g., some solvents) | Low-ppb to ppm | High for gases with IR features | 1–10 min | 5–10 yrs | Medium–High | Fixed monitors for specific VOCs/solvents |

| Electrochemical (specialty) | Redox at electrode surface | Gas-specific | Low-ppb to ppm | High for certain analytes | 5–15 min | 1–3 yrs | Medium | Niche organics where cells exist |

Rule of thumb

- Choose MOS for TVOC/IAQ where cost, size, and low power matter.

- Choose PID for broad-spectrum, high sensitivity, and industrial surveys.

- Choose NDIR/PAS when you need compound specificity and stable baselines.

3) How MOS-Type VOC Sensors Work (IAQ Focus)

MOS sensors use a heated metal-oxide layer (e.g., SnO₂) that adsorbs oxygen on the surface. When reducing VOC molecules contact the surface, they react with adsorbed oxygen, releasing electrons into the conduction band and lowering sensor resistance. The change is proportional to the reducing gas concentration.

Key performance levers

- Temperature: Heater control shapes selectivity, speed, and stability.

- Humidity compensation: Water molecules influence surface reactions; onboard RH/Temp compensation is essential for stable IAQ indices.

- Baseline correction: Algorithms (ABC, auto-zero) track long-term drift in stable environments.

- Mapping to TVOC/IAQ index: Many MOS modules convert raw resistance to TVOC (ppb/ppm equivalent to ethanol) and/or an IAQ Index (0–500).

Winsen MOS-Type VOC Sensors

ZP16-A Air-Quality Detection Module

- Formaldehyde, benzene, carbon monoxide, hydrogen, alcohol, ammonia, smoke of cigarette, essence &etc

- VOC:0-2.000mg/m3 CO2:350-2000ppm CH2O:0-1.000mg/m3

- Read More

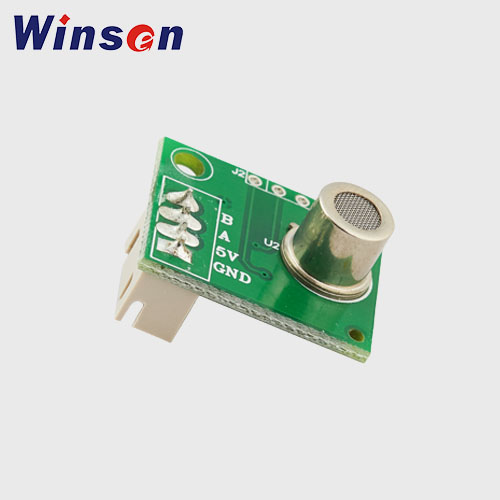

ZP16 Air-Quality Detection Module

- Formaldehyde, benzene, carbon monoxide, hydrogen, alcohol, ammonia, smoke of cigarette, essence &etc.

- 0-10mg/m3

- Read More

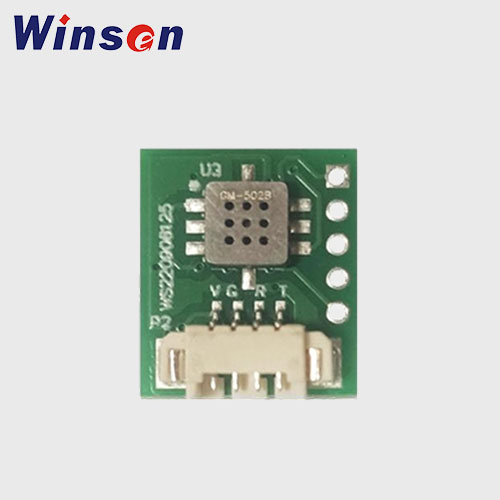

Digital ZM106-VOC Module

- VOC, Ethanol, formaldehyde, toluene and other organic volatiles

- 0~10mg/m3

- Read More

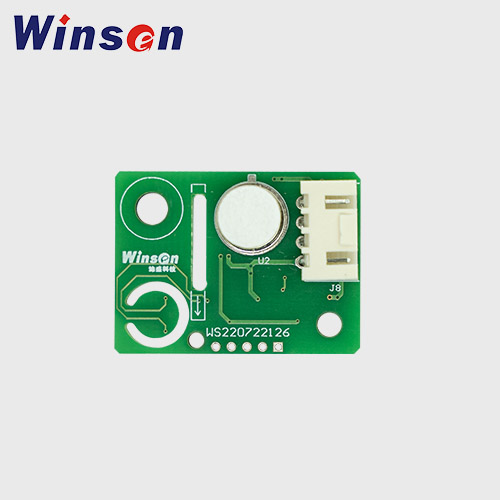

ZPS20 Digital Sensor Module - VOC Temperature Humidity

- Formaldehyde, benzene, VOC, Temperature, Relative humidity

- 0~10mg/m3

- Read More

4) How PID VOC Sensors Work (Industrial Focus)

PID devices expose air to UV photons (commonly 10.6 eV). If a compound’s ionization potential (IP) is below the lamp energy, it is ionized. The resulting ion current is proportional to concentration.

- Advantages: Very quick response, ppb sensitivity, broad coverage.

- Considerations: Requires lamp cleaning/replacement, response factors differ by compound, humidity affects output.

Winsen PID VOC Sensors

5) Performance Specifications You Should Request

When sourcing a VOC sensor/module, ask for the following (and verify with your application conditions):

- Measurement range: e.g., 0–1,000 ppb / 0–10 ppm for IAQ; wider for industrial.

- Resolution & noise floor: e.g., 1–10 ppb.

- Accuracy / Repeatability: e.g., ±(10% reading + offset). For IAQ, consistency matters more than absolute accuracy.

- Response/Recovery (T90/T10): e.g., <10 s (PID), <30–60 s (MOS).

- Drift: Zero/span drift per month; specify at given RH/Temp.

- Operating conditions: −10 to +50 °C, 15–90%RH typical (non-condensing).

- Power consumption: MOS heaters vs. low-power duty-cycling; PID lamp current.

- Interfaces: Analog (V/I), UART/I²C, Modbus/RS-485 for networked devices.

- EMC & certifications: CE/UKCA, RoHS, REACH; for safety areas, see ATEX/IECEx (PID installations).

- Calibration: Fresh-air baseline, single-gas span (often ethanol or isobutylene), and recommended intervals.

- Expected lifetime & warranty.

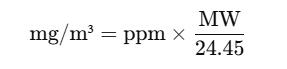

6) Converting Units (Handy Reference)

For a gas with molecular weight MW (g/mol) at 25 °C and 1 atm:

Example (Ethanol, MW = 46.07): 1 ppm ≈ 1.88 mg/m³.

7) Application Scenarios and Design Tips

7.1 Indoor Air Quality (IAQ) & Smart Buildings

-

Use case: CO₂-plus-VOC ventilation control, air purifiers, thermostats, room monitors.

-

Sensor choice: MOS TVOC module with integrated RH/Temp compensation and IAQ index output.

-

Integration tips:

- Avoid direct airflow jets; use a diffusion vent with gentle air exchange.

- Warm-up ~1–3 min; apply soft-start logic.

- Implement ABC (automatic baseline correction) during low-VOC night hours.

- Combine with CO₂ or eCO₂, PM2.5, RH/T for complete IAQ diagnostics.

7.2 Manufacturing & Process Areas (Printing, Coating, Adhesives)

-

Use case: Solvent level checks, curing efficiency, exhaust optimization.

-

Sensor choice: PID for ppb–ppm sensitivity and fast dynamics; NDIR/PAS if compound-specific monitoring is required.

-

Integration tips:

- Sampling lines with filters (PTFE) to keep aerosols out.

- Keep lamp/sensor heads away from condensing vapors.

- Establish alarm tiers (warning/action) and interlock with ventilation.

7.3 EHS & Compliance

-

Use case: Personal exposure screening, area monitors, fence-line monitoring.

-

Sensor choice: PID or high-stability MOS with data logging.

-

Integration tips:

- Calibrate with traceable span gas (e.g., isobutylene for PID, ethanol for MOS).

- Account for response factors across target compounds.

- Ensure bump tests before shifts; maintain calibration records.

7.4 Transportation & Automotive Cabin

- Use case: In-cabin odor, materials off-gassing, smart recirculation.

- Sensor choice: Low-power MOS with rapid wake-up.

- Integration tips: Duty-cycle heaters, place near return airflow, compensate for RH/T and H₂ cross-sensitivity.

7.5 Labs, Cleanrooms & Pharma

- Use case: Solvent storage/dispensing rooms, chromatograph vent areas.

- Sensor choice: PID or compound-specific IR/PAS.

- Integration tips: HEPA/charcoal filtration interplay can create transients—log and filter signals.

8) Cross-Sensitivity, Interference, and Data Treatment

- Humidity & Temperature: Affect adsorption kinetics (MOS) and ion transport (PID). Use multi-parameter compensation and temperature-normalized outputs.

- Hydrogen & CO: Some MOS devices respond strongly; consider compensation channels or algorithms.

- Cleaning agents/alcohols: Spikes after routine cleaning are normal. Use median filters and rate-of-change limits to avoid false alarms.

- Aging & contamination: MOS surfaces age slowly; PID lamps may foul with high-boiling compounds—schedule maintenance.

- Signal processing: Exponential smoothing, moving average, outlier rejection, and baseline tracking improve stability without hiding real events.

9) Typical Deliverables from Winsen

- Sensor elements and ready-to-integrate modules (MOS TVOC, PID options for industrial partners).

- Evaluation kits & sample code (UART/I²C).

- Compensation libraries for RH/T and baseline tracking.

- Application notes for IAQ, HVAC, and industrial safety.

- Customization (form factor, interface, pre-calibration range) for OEM programs.

10) Frequently Asked Questions (FAQ)

Q1: What is the difference between TVOC and a single-gas reading (e.g., ethanol)?

A: TVOC is a composite indicator. Many MOS sensors are calibrated to an ethanol equivalent to provide a consistent index across broad VOC mixtures. For compound-specific control, consider PID or IR/PAS solutions.

Q2: Can a VOC sensor detect formaldehyde (HCHO)?

A: Many MOS VOC sensors respond to aldehydes, but the output is not compound-specific. If you need selective HCHO, use a dedicated HCHO sensor (electrochemical or photoacoustic).

Q3: Why does the reading rise after cleaning?

A: Alcohol-based cleaners and fragrances are VOC-rich and generate short-term spikes. Apply averaging and allow air exchange to stabilize.

Q4: Do I need frequent calibration?

A: For IAQ MOS sensors, perform baseline auto-correction regularly and consider annual bump checks. PID devices require lamp maintenance and more frequent span checks.

Q5: How fast is the response?

A: PIDs respond in seconds; MOS modules typically reach T90 in 30–60 s under standard conditions.

Q6: How do humidity and temperature affect readings?

A: Both change surface kinetics and carrier mobility. Use sensors with integrated RH/T compensation and keep the device non-condensing.

Q7: Can I use VOC sensing for demand-controlled ventilation (DCV)?

A: Yes. Map TVOC/IAQ index to ventilation steps with hysteresis and minimum-air safeguards. Combine with CO₂ for robust control.

Q8: What if I only care about odor?

A: TVOC/IAQ index correlates well with perceived odor intensity. For product testing or fragrance control, tune thresholds via field studies.

11) Why Choose Winsen

- Complete portfolio: From MOS TVOC modules for IAQ to PID options for industrial partners.

- Manufacturing strength: Scalable production, strict quality control, and consistent batch-to-batch performance.

- Integration support: Electrical/mechanical reference designs, calibration and compensation know-how, and rapid customization.

- Global shipping & service: Fast samples, OEM/ODM collaboration, and multilingual technical support.

Contact Us

Looking for the right VOC sensing solution for your device or project? Contact Winsen to discuss your range, interface, and certification requirements. Our engineers can recommend the optimal MOS, PID, or IR/PAS pathway and provide evaluation kits for rapid prototyping.