Infrared PM Dust Sensor — Principles, Specifications, Applications & OEM Integration

1) What Is an Infrared PM Dust Sensor?

An Infrared (IR) PM dust sensor estimates airborne particle concentration using an infrared LED and a photodetector. As particles pass through the optical path, they scatter and attenuate the IR beam. The received signal is processed to estimate mass concentration—commonly PM2.5 and PM10—sufficient for trend detection, ventilation control, and alarm thresholds at an attractive BOM cost and low power.

Typical use cases: wall-mounted IAQ nodes, thermostats, fan/air-cleaner triggers, smart plugs/relays for exhaust fans, and building demand control where budget matters.

2) Working Principle (IR Attenuation/Scatter)

- IR emission: A stable IR LED illuminates an internal sampling chamber.

- Interaction: Airflow brings particles across the beam; particles scatter/attenuate IR light.

- Sensing: A photodiode/phototransistor measures the received intensity; pulses/level changes correlate with particle load.

- Signal processing: Analog conditioning + firmware map signal to PM2.5/PM10 mass using factory/field calibration curves and assumed particle density/shape.

- Compensation: Temperature/RH inputs and baseline tracking improve stability in real deployments.

IR designs emphasize simplicity and economy. Compared with laser PM sensors, IR sensors typically have higher minimum detectable size (~0.5–1.0 µm effective) and coarser linearity, which is acceptable for threshold control and budget IAQ.

3) Key Advantages

- Cost-effective: Lowest BOM for PM triggering and trending.

- Low power: Suited to always-on building nodes and appliances.

- Fast integration: PWM/analog or UART (model-dependent), simple host drivers.

- Compact footprint: Easy to embed in wall sensors, switches, and vents.

- Robust for triggers: Stable enough for warning/action thresholds and fan interlocks.

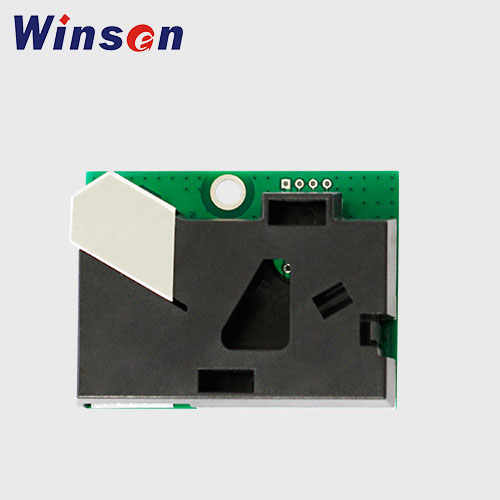

4) Winsen Infrared PM Dust Sensor

5) Infrared vs. Laser — When to Choose IR

| Attribute | Infrared PM Dust Sensor | Laser PM Sensor |

|---|---|---|

| Minimum detectable size | ~0.5–1.0 µm (effective) | ≈0.3 µm (fine particle fidelity) |

| Metrics | PM2.5 / PM10 mass (limited binning) | PM1.0/PM2.5/PM10 + size-binned counts |

| Cost & power | Lower | Higher |

| Linearity for PM2.5 | Adequate for thresholds | Better (analytics, AQI accuracy) |

| Best for | Budget IAQ, triggers, fan control | Premium IAQ, purifiers, research analytics |

Rule of thumb: If your product needs basic PM2.5 alarm/ventilation control at scale, choose IR. If you need PM1.0 fidelity, counts, or premium user analytics, choose Laser.

6) Data Quality & Compensation

- Humidity: Hygroscopic growth at high RH inflates optical mass; apply RH compensation (table or polynomial).

- Aerosol type: Calibrate density/shape factors for your dominant aerosol (cooking smoke vs mineral dust).

- Flow stability: Provide a consistent diffusion path or gentle forced flow; avoid backpressure and recirculation.

- Aging/soiling: IR windows can foul over time—add maintenance flags or self-clean bursts (if a fan is present).

7) Mechanical Integration

- Inlet design: Short, smooth path with anti-static, matte plastics; avoid sharp turns that deposit particles.

- Screens & filters: Insect screens and coarse pre-filters protect optics; keep pressure drop low.

- Placement: Sample representative room air; avoid direct HVAC jets, corners, and warm exhausts.

- Orientation: Follow module guidance—some chambers are orientation-sensitive.

8) Electrical & Firmware Integration

-

Power integrity: Decouple IR LED drive from logic rails (RC/LC filtering); manage startup currents.

-

Interface:

- PWM/Analog: Map duty or voltage to PM estimate; apply a smoothing filter and hysteresis for alarms.

- UART (if available): Parse frames for PM2.5/PM10 and status bytes; verify checksum.

-

Warm-up masking: Ignore first 5–30 s after power-up.

-

Filtering: Use median + moving average (5–15 s); add rate-of-rise path for rapid smoke events.

-

AQI mapping: Implement US/EU/China AQI tables and hysteresis to avoid display/relay chatter.

9) Applications & Recommended Setups

A) Wall-Mounted IAQ / Thermostat Nodes (Budget)

- Goal: Turn fans or alerts on when PM2.5 exceeds thresholds.

- Setup: IR PM sensor with PWM/analog output → MCU comparator/ADC → relay/triac control; log 10–60 s averages.

- Tip: Pair with CO₂ and RH/T for context; show AQI color on UI.

B) Bathroom/Kitchen Exhaust Automation

- Goal: Remove cooking/oil aerosols and sprays promptly.

- Setup: IR PM + rate-of-rise detection + minimum on-time (e.g., 5–10 min) to avoid short cycling.

- Tip: Add a mask window during cleaning sprays to reduce nuisance alarms.

C) Building BMS Demand Control (Large Scale)

- Goal: Budget IAQ coverage across many rooms/zones.

- Setup: IR PM nodes networked to Modbus/BACnet via gateway; trend logs for compliance and maintenance planning.

- Tip: Schedule periodic validation and optics checks.

D) Warehouse/Light-Industrial Trend Monitoring

- Goal: Alarm on dust bursts near lines/packaging.

- Setup: IR PM with pre-filter, audible/visual alarms, and latched events for audit trails.

10) FAQs

Q1. Are IR PM sensors accurate enough for AQI displays?

They provide good correlation for PM2.5/PM10 after RH and aerosol adjustments. For PM1.0 and research-grade analytics, use laser PM.

Q2. Why do values spike during cooking or cleaning?

Oil mist and detergents scatter strongly—expected behavior. Use event masks, rate-of-rise with hold-offs, and clear user prompts.

Q3. Can I run the sensor in ducts?

Yes, with a bypass channel and gentle fan to stabilize flow; avoid condensation and excessive temperature gradients.

Q4. How often should I service the sensor?

Design for 6–12 month checks (environment-dependent) or use contamination flags/self-clean bursts to extend intervals.

Q5. Do I need number counts?

IR designs generally focus on mass. If you need counts/size bins, choose a laser PM model.

11) Why Choose Winsen for Infrared PM

- Economical, scalable solutions for large IAQ deployments and appliances.

- Integration-ready outputs (PWM/analog/UART), compact housings, and clear reference designs.

- Engineering support for RH compensation, alarm logic, and EMC-robust layouts.

- Customization of output mapping, enclosure features, and firmware thresholds to fit your product roadmap.

Talk to Our Engineers

Share your budget, interface, airflow constraints, and target thresholds. We’ll recommend the optimal Winsen Infrared PM Dust Sensor variant and provide evaluation kits, protocols, and mechanical references to accelerate your launch.