Solid-State Battery Commercialization Accelerates — H₂S Sensors Become a Safety “Must-Have”

Solid-state batteries are moving from concept to industrial reality. With higher safety potential, longer cycle life, and the promise of higher energy density, they’re widely viewed as a next-generation platform for electric mobility and advanced energy systems.

But one truth remains: no battery technology is “100% risk-free.” In particular, sulfide-based solid electrolytes—one of the most promising routes—can generate a new safety challenge that manufacturers must address head-on: hydrogen sulfide (H₂S).

When sulfide electrolyte materials contact moisture, experience high-temperature abuse, or the cell structure is mechanically damaged, decomposition reactions can occur and release H₂S, a colorless, highly toxic, and flammable gas. That means early detection and rapid warning are no longer optional—they become part of the minimum safety architecture for commercialization.

Why Sulfide Solid Electrolytes Create a Unique H₂S Risk

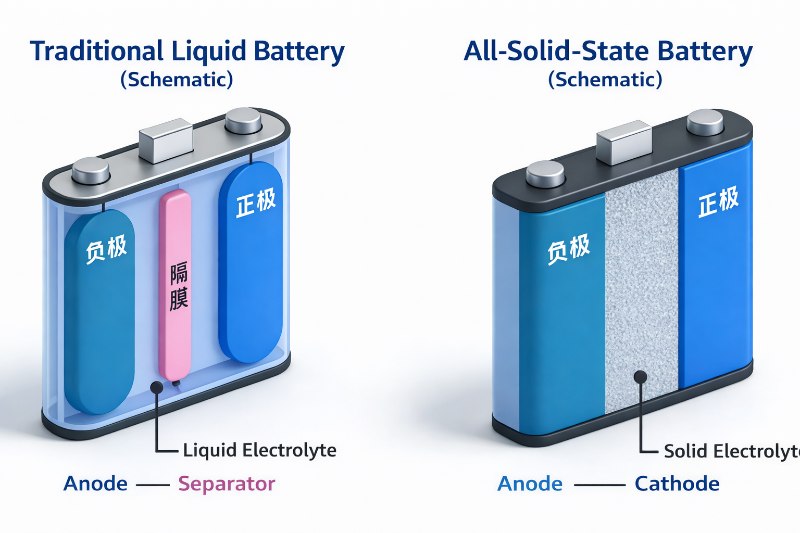

Solid-state batteries replace the liquid electrolyte + separator structure found in traditional lithium-ion cells with a solid electrolyte. Depending on the solid electrolyte chemistry, solid-state routes are commonly grouped into:

- Polymer electrolytes

- Oxide electrolytes

- Sulfide electrolytes (often considered the highest-performance pathway)

Sulfide electrolytes are attractive for ionic conductivity and interface engineering—but they can be sensitive to real-world stressors:

- Moisture intrusion (manufacturing, storage, maintenance, or packaging failure)

- Thermal abuse (overheating, abnormal operating conditions)

- Mechanical damage (cell rupture, impact, enclosure damage)

In these scenarios, H₂S can be generated and accumulate, creating both personnel exposure risk and secondary hazards like ignition in confined spaces.

H₂S Detection Becomes the “Safety Valve” for Solid-State Battery Industrialization

The goal isn’t just to detect gas after a major event. The real value is:

- Detect early micro-leaks

- Trigger ventilation/interlocks immediately

- Prevent escalation

- Provide traceable safety data for production and quality systems

As solid-state batteries expand beyond traction packs and into broader markets—low-altitude economy (drones/eVTOL), humanoid robotics, consumer electronics, and stationary energy storage—the demand for compact, reliable, scalable gas detection grows rapidly.

What a Solid-State Battery H₂S Monitoring Solution Must Deliver

For production and deployment environments, H₂S sensing needs to be engineered for practicality:

1) Coverage of safety thresholds across scenarios

Solid-state battery risk scenarios range from minor seepage to abnormal release. A usable solution must cover relevant concentration windows with stable performance.

2) Early-warning resolution

Detecting small concentration changes provides the time window needed for ventilation, shutdown, and evacuation logic.

3) Fast response

In confined or semi-confined battery systems, H₂S can rise quickly. Second-level response helps protect people and assets.

4) Stability and reliability

Battery factories and test labs are demanding environments. The sensor module must maintain stable output over time, minimize drift, and support maintenance plans.

5) Easy integration and flexible alarm strategy

Different OEMs and battery makers need different thresholds and control logic. A professional solution should allow free selection of warning points and integrate cleanly into host controllers.

Winsen Electrochemical H₂S Leak Sensor Module: Built for Early Warning

To address this emerging safety need, Winsen introduces an electrochemical H₂S sensor module designed for solid-state battery safety monitoring. The module pairs:

- an electrochemical H₂S sensing element

- a high-performance microprocessor

- intelligent algorithms for signal processing and stability

This combination enables strong responsiveness, stable operation, and accurate detection—helping users capture H₂S concentration changes quickly and reliably.

Key performance highlights (from your content)

- Detection range: 0–100 ppm (covers common safety monitoring needs)

- Resolution: 0.1 ppm (captures early micro-leak signals)

- Response speed: second-level response (buys critical time for emergency handling)

- High integration: compact structure for easier installation

- Flexible alarms: supports OEM/battery makers to set warning thresholds at chosen points

Where to Deploy H₂S Sensors in Solid-State Battery Projects

A “real” safety design is not one sensor in one place—it’s a risk-based monitoring layout. Typical deployment points include:

1) R&D labs and pilot lines

- material handling and mixing

- electrolyte processing zones

- prototype cell assembly areas

- abuse testing chambers (thermal, puncture, crush)

2) Manufacturing and production facilities

- dry room boundaries and critical process stations

- formation and aging areas

- equipment enclosures where leaks may accumulate

- ventilation ducts and exhaust monitoring points

3) Pack systems and storage

- pack enclosures (early abnormal gas detection)

- storage rooms and warehouses

- transportation containers (as required by safety policy)

Beyond Power Batteries: Expanding Application Map

Solid-state battery adoption will not stop at EV power packs. It is expected to extend into:

- Low-altitude economy (drones, eVTOL, aerial robotics)

- Humanoid robotics (high density, compact power systems)

- Consumer electronics (thin form factor, high energy demand)

- Energy storage (large installations need scalable safety sensing)

As the battery platform expands, H₂S sensing becomes a standardized safety layer—similar to how smoke, temperature, and pressure sensing became standard in earlier industrial safety systems.

Recommended Image Placement + Alt Text (for SEO)

You shared three images—here’s a clean way to use them in the article:

Header / Section image (battery structure comparison) Alt text: “Traditional liquid electrolyte battery vs solid-state battery structure diagram (electrolyte and separator replaced by solid electrolyte)”

Product highlight image (H₂S sensor module specs) Alt text: “Electrochemical hydrogen sulfide (H₂S) leak sensor module for solid-state battery safety monitoring, 0–100 ppm range, 0.1 ppm resolution, fast response”

Application map image (future market coverage) Alt text: “Solid-state battery application scenarios: low-altitude economy, humanoid robots, consumer electronics, and energy storage”

FAQ

What makes H₂S especially dangerous in solid-state battery scenarios?

H₂S is toxic at low concentrations and can also be flammable—so early detection is essential to avoid exposure and secondary hazards.

Why can’t safety rely on “smell” or human awareness?

H₂S can be difficult to manage by human perception alone, especially in industrial environments with ventilation, competing odors, and fast-changing conditions. Instrument-based monitoring is the reliable approach.

Why choose electrochemical sensing for H₂S?

Electrochemical sensing is widely used for toxic gas monitoring because it can deliver low-ppm detection with low power and good integration potential (module design and system calibration matter).

What range should I choose for H₂S monitoring?

For early warning and safety threshold coverage, a 0–100 ppm monitoring design is common. Final selection depends on your risk assessment, space volume, ventilation rate, and safety policy.

Where should I install sensors in a battery plant?

Prioritize points where gas can accumulate: equipment enclosures, critical process areas, testing chambers, and ventilation/exhaust paths.

Can alarm thresholds be customized?

Yes—your content indicates OEMs/battery makers can choose warning points freely, enabling different strategies for R&D, pilot, and mass production environments.

Planning a solid-state battery H₂S safety monitoring layout? Contact Winsen for the H₂S sensor module datasheet, integration guide, and recommended deployment strategy based on your electrolyte route, process flow, and facility ventilation design.