Product Refresh, Experience Upgrade: The New FRn Series MEMS Thermal Mass Flow Sensors Are Now Available

In industrial process control, environmental monitoring, medical devices, and energy management, real-time gas flow measurement must be accurate, repeatable, and stable over long periods. Thermal mass flow sensing has become a preferred approach in demanding applications because it offers simple structure, low pressure loss, and a wide measurement range.

Winsen’s new-generation FRn series builds on the proven FR platform and focuses on what engineers care about most: drift suppression, strong long-term stability (zero and full scale), and easy integration—now with I²C digital output and analog voltage output options.

What Is a Thermal Mass Gas Flow Sensor?

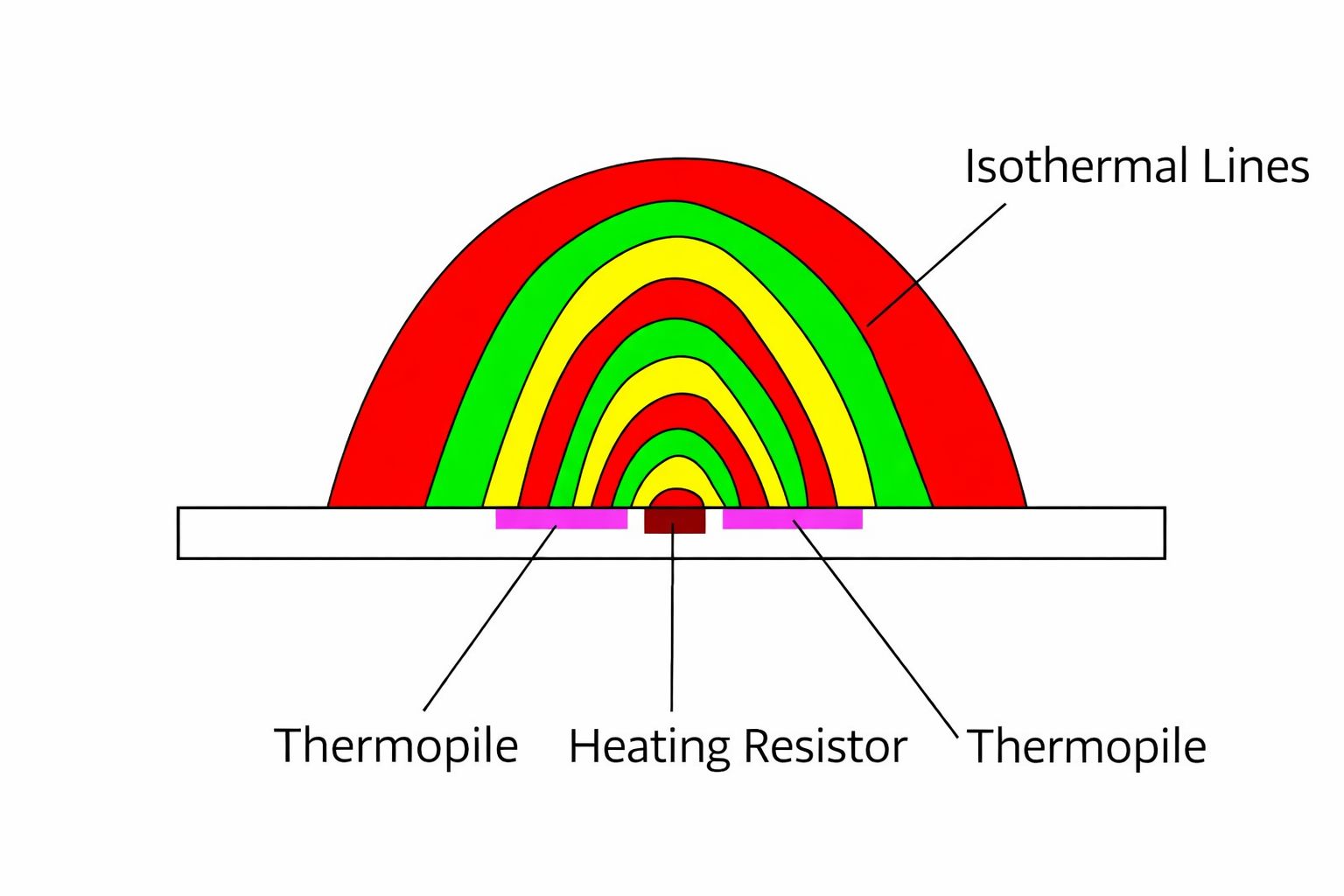

A thermal mass flow sensor measures flow using heat transfer. In a typical MEMS thermal design:

- A micro heater adds heat to the flow channel.

- Temperature sensors (often arranged upstream and downstream) detect how the moving gas shifts the temperature field.

- The resulting temperature difference (or related signal) is converted into a flow value.

This architecture is widely used in thermal mass flow sensing designs (heater + multiple temperature sensors).

Why “mass flow” is valuable

Because the measurement is driven by heat transfer related to mass flow, thermal sensors are widely used where repeatable control matters (e.g., proportional control, sampling, and stable process regulation). Winsen also highlights thermal mass sensors’ broad suitability across industrial control, portable instruments, and environmental monitoring.

The New FRn Series: Upgraded Stability, Cleaner Output Options

On Winsen’s flow sensor lineup page, FRn series models include FRn03P, FRn03H, FRn06, and FRn20.

Among them, the micro-flow versions are positioned for compact systems and tight integration.

FRn03H: Improved zero-point and full-scale stability

FRn03H is described as an upgrade based on FR03H, with significantly improved zero-point stability and full-scale signal stability, supporting low pressure loss and broad gas measurement use.

FRn03P: Surface-mount, MEMS thermal micro-flow sensing

FRn03P is designed for micro-flow process control, uses the MEMS thermal principle, and is intended for dry, clean gases. It also supports surface-mount installation, making it suitable for multi-sensor integration in confined spaces.

Key Advantages Engineers Will Notice

1) Ultra-low start-up flow + high sensitivity

The FRn03P manual lists high sensitivity with very low start-up flow as a core feature—important for detecting subtle flow changes in sampling, dosing, and micro-control loops.

2) Long-term signal stability and repeatability

FRn03P emphasizes high stability and repeatability across the full scale, and FRn03H highlights improved zero/full-scale stability—both aimed at reducing recalibration burden and drift-related maintenance.

3) Easy integration: I²C digital + analog voltage outputs

FRn03P supports:

- Digital I²C output (100 kHz)

- Analog output: 0.5–4.5 VDC

This gives you flexibility to integrate into MCUs, PLC gateways, data acquisition systems, or mixed-signal controllers.

4) Low pressure loss design philosophy

Thermal mass gas flow sensors are widely adopted partly due to very small pressure loss and broad application fit.

Example Specs (FRn03P Reference)

Below are key reference parameters from the FRn03P Series Manual (V1.1, 2025-09-30).

| Item | FRn03P (Reference) |

|---|---|

| Flow range options | Max flow selectable up to 50–5000 SCCM (by model) |

| Accuracy | ±(2 + 0.5FS)% |

| Repeatability | 0.50% |

| Response time | ≤ 50 ms |

| Max working pressure | 500 kPa |

| Output | I²C + 0.5–4.5V analog |

| Operating voltage | 5–15 VDC |

| Operating current | ≤ 30 mA |

| Operating temperature | 0–50°C |

| Medium | Dry, clean, non-corrosive gases |

| Calibration basis | Default calibrated with air at 20°C, 101.325 kPa |

Typical Applications for FRn Series Flow Sensors

Thermal mass gas flow sensors are widely used in:

- Industrial process control (micro-flow regulation, dosing, sampling)

- Medical equipment (flow monitoring and control subsystems)

- Portable instruments (compact, low pressure loss measurement paths)

- Environmental monitoring equipment / air sampling (stable flow feedback for accurate sampling)

Winsen also provides application-focused guidance for air sampler integration and positions MEMS thermal mass flow sensors (e.g., FR08-H0A) as strong choices for sampling devices.

Standards & Industry Background

Winsen notes it participated in drafting the industry standard JB/T 13111-2017 (Thermal Mass Flow Sensor).

The standard’s basic registration info (JB/T 13111-2017; published 2017-04-12, implemented 2018-01-01) is listed on China’s National Public Service Platform for Standards.

Quick Selection Guide

Choose FRn series if you need:

- Micro-flow process control with fast response and stable signals

- I²C output for digital integration and diagnostics

- Analog 0.5–4.5V output for legacy controllers or quick validation

- Low pressure loss with compact sensor structure

If you’re unsure which model fits your range and installation, start from the full lineup here:

Flow Sensor List: https://www.winsen-sensor.com/flow-sensor/

FAQ

What’s the difference between FR and FRn series?

FRn is positioned as an upgraded generation focused on improved zero-point and full-scale signal stability, helping reduce drift over time and across working conditions.

Does FRn support digital communication?

Yes. FRn03P supports I²C (100 kHz).

Can I use FRn sensors with analog-only systems?

Yes. FRn03P provides 0.5–4.5V analog output in addition to I²C.

What gases can FRn measure?

FRn03P is specified for dry, clean, non-corrosive gases. For other media, consult Winsen to confirm compatibility and calibration needs.

How are FRn sensors calibrated?

FRn03P indicates default calibration using air at 20°C and 101.325 kPa, with special calibration available by customer requirement.

Get FRn Series Datasheets & Application Support

If you tell us your gas type, target flow range (SCCM/SLM), pressure, and preferred I²C vs analog output, we can recommend the best FRn model and provide the relevant integration notes and documentation.