Integration ≠ Simple Assembly: True Multi-in-One Sensors Redefine In-Cabin Air Quality

Automotive technology is shifting from “add more hardware” to “achieve more with less.” In EVs and intelligent vehicles, every gram of weight, every cubic centimeter of space, and every watt of power matters. Cabin comfort is no longer defined only by temperature—it now includes air cleanliness, freshness, humidity, and cognitive comfort (avoiding drowsiness from high CO₂).

This is why multi-in-one in-cabin air quality sensors have become a mainstream direction: they help OEMs deliver better user experience while controlling BOM, packaging, and system complexity.

Does putting multiple sensors in one box equal integration?

Not really.

Many “integrated” solutions are simply modules placed side-by-side—separate sensing blocks, separate sampling timing, separate compensation behaviors, and delayed data collaboration. That approach often creates new problems:

- More harnessing and connectors than expected

- Inconsistent sampling (e.g., PM and AQS not synchronized)

- Calibration complexity (each sensor behaves differently across temperature/humidity)

- Slower control decisions for HVAC (data arrives in different time windows)

True integration means: hardware consolidation + algorithmic synergy—where the sensing stack is designed as one coordinated “system,” delivering 1 + 1 > 2 performance in real-world cabins.

Why in-cabin air quality is a tougher problem than it looks

A modern cabin is a dynamic environment:

- Outside pollutants change rapidly (traffic exhaust, tunnels, industrial zones)

- Occupancy changes CO₂ quickly during recirculation

- Humidity and temperature affect perceived comfort and fogging risk

- VOCs and odors may spike from interior materials or external sources

A single parameter can’t represent the “real” cabin air quality. The system needs multi-dimensional perception, then a controller must decide:

- Fresh air vs recirculation

- Filter/ionizer/purifier activation

- Fan speed and air distribution

- Energy-optimized ventilation strategy (especially in EVs)

That’s why multi-parameter sensing (PM2.5 + CO₂ + AQS + T&H + VOC) has become the practical foundation for “smart cabin.”

What a “true” multi-in-one sensor should deliver

A real multi-in-one automotive module is not just multiple sensors inside one housing. It is a co-designed architecture with:

1) Unified airflow & mechanical design

One airflow path, one sampling environment—so different sensing elements “see” comparable air conditions.

2) Shared processing and synchronized sampling

A single high-performance MCU can coordinate sampling intervals and data timing, enabling real sensor fusion instead of post-hoc aggregation.

3) Built-in compensation and cross-analysis

Temperature/humidity compensation plus multi-parameter correlation can reduce false triggers and improve stability over real driving cycles.

4) Automotive communication readiness

Direct digital integration via CAN/LIN (or other automotive buses) avoids extra analog conditioning and makes ECU integration faster.

Winsen multi-in-one in-cabin modules: ZMHS10 & ZMHS11

Winsen’s approach reflects the “true integration” direction: combining particulate sensing, gas sensing, CO₂, and environmental parameters in one coordinated module for cabin HVAC and purification control.

ZMHS10- All-in-one Air Quality Sensor

- PM2.5, CO2, AQS, Temperature and humidity

- PM2.5:0~1000μg/m³

CO2:400~10000ppm

AQS:CO: 1~5000ppm, NOx: 0~10ppm, NH3: 1~300ppm

Temperature:-40~125℃

Humidity:0~100%RH

- Read More

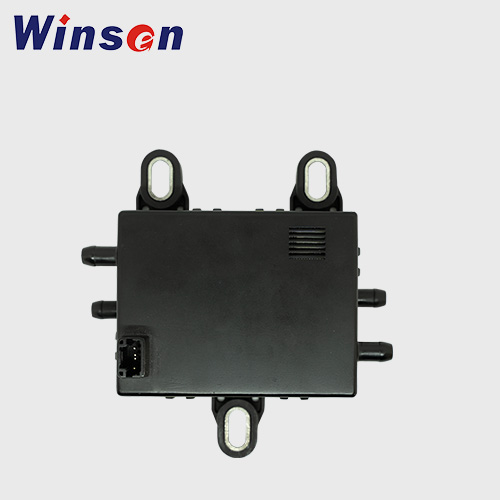

ZMHS11 Vehicle-Mounted Multi-In-One Air Quality Detection Module

- PM2.5, CO2, AQS, Temperature & Humidity, Pressure

- Read More

ZMHS10: Single-channel multi-in-one air quality sensor (HVAC-ready)

ZMHS10 is an integrated, miniaturized module designed for automotive air conditioning systems, capable of simultaneously detecting PM2.5, CO₂, AQS, temperature, and humidity with digital output.

Key capabilities (from official specs)

-

Targets: PM2.5, CO₂, AQS, Temperature & Humidity

-

Detection range:

- PM2.5: 0–1000 μg/m³

- CO₂: 400–10000 ppm

- AQS: CO 1–5000 ppm, NOx 0–10 ppm, NH₃ 1–300 ppm

-

Detection principles: Mie scattering (PM), NDIR (CO₂), MOS (AQS), plus T/H sensing

-

Output: CAN/LIN (customizable)

-

Response time: T90 < 15 s

-

Notes: IATF16949 compliant

Where ZMHS10 fits best

- Car air conditioning system (fresh air/recirculation control)

- In-cabin purifier / air cleaner

- Vehicle air quality detector / cabin monitoring ECU

ZMHS11: Dual-channel multi-in-one air quality module (expanded sensing & redundancy)

ZMHS11 is positioned for applications needing dual dust detection channels plus additional environmental parameters. The published product introduction describes integration of:

- dual particulate/dust channels

- CO₂ + AQS

- temperature & humidity

- pressure sensor

- CAN or LIN communication

This dual-channel concept is especially valuable for:

- Consistency and cross-checking (better reliability across varying airflow conditions)

- More robust cabin/outside air strategies in premium HVAC/clean-air systems

- Smarter control when combined with pressure/altitude effects (e.g., ventilation strategy adjustments)

Quick comparison: traditional vs true multi-in-one

| Item | Traditional “separate sensors” | True multi-in-one module |

|---|---|---|

| Hardware | Multiple PCBs/housings | Single consolidated module |

| Integration | More wiring + connectors | Simplified harness & assembly |

| Data timing | Asynchronous readings | Coordinated sampling + fusion |

| Control strategy | Slower, less contextual | Faster HVAC decisions |

| Calibration | Multiple behaviors to manage | Centralized compensation logic |

| Packaging | Space-consuming | Compact footprint (can free design space) |

How sensor fusion improves HVAC control in real vehicles

A multi-in-one sensor can support “smart” HVAC decisions that isolated sensors struggle to achieve:

- Recirculation logic that makes sense: outside AQS spike + rising PM → recirc; but if CO₂ is rising too fast → controlled fresh air pulse

- Anti-fog comfort strategy: humidity trend + cabin temp delta → adjust airflow distribution proactively

- Energy-aware ventilation in EVs: keep air fresh while minimizing HVAC power draw by optimizing fresh-air duty cycle

- More trustworthy purification triggers: PM event + AQS change + VOC behavior → reduce false positives

Integration checklist for OEMs and Tier-1s

When implementing an in-cabin multi-in-one sensor, these decisions matter:

-

Placement

- Avoid direct water condensation zones

- Ensure representative airflow (not dead zones)

-

Air channel design

- Stable sampling airflow improves repeatability

-

EMC and electrical noise

- Automotive environments are noisy—choose modules designed for robust integration

-

Communication protocol

- CAN/LIN can simplify ECU integration and diagnostics compared to analog

-

Calibration strategy

- Even factory-tested modules benefit from system-level validation in the final HVAC design and vehicle platform (aging, drift checks)

Customization: “multi-in-one” should be configurable, not fixed

Different vehicle trims and regions have different needs (cost, feature set, regulation, customer expectation). A scalable multi-in-one platform enables:

- Optional sensing combinations (e.g., add VOC, pressure, or expand gas targets)

- Output protocol customization (CAN/LIN variants)

- Algorithm tuning for specific cabin designs and filter/purifier architectures

FAQs

What does AQS mean in automotive applications?

AQS usually refers to an Air Quality Sensor used in automotive HVAC to detect pollution levels and trigger intake air control (e.g., switching fresh/recirculation). Winsen’s AQS module ZM102 is designed for automotive air conditioning and links air quality to intake air control logic.

Why monitor CO₂ in a car cabin?

CO₂ is a strong proxy for ventilation adequacy. Excessive CO₂ can increase fatigue and discomfort; in-vehicle CO₂ monitoring supports safer and more comfortable HVAC strategies.

Why combine PM2.5 and AQS together?

PM2.5 captures particulate pollution, while AQS responds to gaseous pollutants. In real traffic scenarios, these do not always rise together—fusion improves decision accuracy.

Is a multi-in-one sensor mainly about saving space?

Space savings are important, but the bigger gain is system-level intelligence: synchronized sampling and algorithmic cross-analysis enable better HVAC control.

What output interfaces are common for automotive integration?

CAN and LIN are commonly used in automotive networks; ZMHS10 supports CAN/LIN (customizable) for integration into vehicle systems.

How fast should an in-cabin air quality module respond?

Fast response improves user experience and safety. ZMHS10 lists T90 < 15 s response time.

Can multi-in-one modules be used for both inside and outside air?

Yes—many HVAC strategies rely on inside/outside comparisons (pollution avoidance + CO₂ management). Proper placement and airflow design are key.

How do OEMs choose between ZMHS10 and ZMHS11?

- Choose ZMHS10 for compact, single-channel all-in-one sensing with PM2.5 + CO₂ + AQS + T/H.

- Consider ZMHS11 when dual dust channels and added parameters (like pressure) are needed for higher robustness and premium strategies.

Conclusion: the “smart olfactory hub” for the healthy cabin era

The cabin is becoming a health and comfort space, not just a place to sit. Multi-in-one air quality modules represent the next step: from single-parameter monitoring to multi-dimensional perception, and from passive response to active, intelligent protection.

By consolidating sensing hardware and enabling algorithmic synergy, modules like ZMHS10 (and dual-channel options like ZMHS11) help automakers and Tier-1s build cabins that feel cleaner, smarter, and more energy-efficient.