Gas-Safety Tables: The Practical Tables Every Gas Safety Program Uses

Gas-safety tables are the quick-reference charts that safety teams, plant engineers, and OEM designers rely on to make fast, consistent decisions—especially when the situation is time-sensitive (confined spaces, hot work, leak response, alarm events).

High-ranking gas safety resources tend to cover the same “core tables” again and again—oxygen thresholds, LEL/UEL (flammability) charts, exposure limits (TWA/STEL/Ceiling), IDLH values, and hazard labeling systems (NFPA 704/GHS)—then connect them to detector selection, placement, alarm setpoints, and emergency response.

What Are Gas-Safety Tables Used For?

Gas-safety tables help you quickly answer questions like:

- Is the atmosphere flammable (in %LEL) or oxygen-deficient?

- What is the LEL/UEL for the target gas?

- What exposure limit applies—TWA, STEL, or Ceiling?

- At what concentration is it IDLH (escape/respirator-critical)?

- What is the hazard severity in NFPA 704 (fire responders / labeling)?

- Where should a detector be mounted (high vs low) and what should it do at each alarm level?

The 7 Most Important Gas-Safety Tables

1) Oxygen Safety Table (Confined Space “First Check”)

In gas work, oxygen is usually checked before anything else because oxygen deficiency can kill silently, and oxygen enrichment increases fire risk.

Key OSHA thresholds (commonly referenced for confined space work):

- Oxygen deficient: < 19.5% O₂ by volume

- Oxygen enriched: > 23.5% O₂ by volume

Oxygen Safety Table

| Condition | O₂ (% by volume) | Why it matters | Typical action |

|---|---|---|---|

| Oxygen deficient | < 19.5% | Asphyxiation risk | Ventilate / entry controls / rescue plan |

| Normal | ~20.9% | Baseline | Continue testing other hazards |

| Oxygen enriched | > 23.5% | Higher ignition/flash fire risk | Remove enrichment source, control ignition |

(These definitions are explicitly provided in OSHA confined space standard text.)

2) LEL/UEL Gas Safety Table (Explosive Limits)

LEL (lower explosive limit) and UEL (upper explosive limit) define the flammable range in air. Many authoritative references also use LFL/UFL as equivalent terms.

Why %LEL appears in detectors

Most fixed/portable combustible detectors report %LEL, because it’s the most direct “how close are we to ignition threshold?” number.

Conversion formula (gas-specific):

- Gas (%vol) = (%LEL / 100) × LEL (%vol)

To interpret LEL/UEL fields and units, NIOSH clarifies that LEL/UEL are expressed as % by volume in air (room temperature unless noted).

LEL/UEL Quick Table (Common Gases)

| Gas | LEL (%vol) | UEL (%vol) | Notes |

|---|---|---|---|

| Methane (Natural Gas) | 5 | 15 | lighter than air (often rises) |

| Propane (LPG) | 2.1 | 9.5 | heavier than air (often sinks) |

| LPG (Propane/Butane mix) | 2.1 (propane) / 1.9 (butane) | 9.5 / 8.5 | varies by blend |

| Hydrogen | 4 | 75 | wide flammable range |

| Carbon Monoxide | ~12.5 | ~74–75 | toxic + flammable |

These values are widely published in government/official chemical databases and pocket guides (e.g., National Oceanic and Atmospheric Administration CAMEO Chemicals for methane/propane/hydrogen, plus NIOSH Pocket Guide for LPG).

More about LEL and UEL: LEL vs UEL Explained: Flammable Range, %LEL, Alarm Setpoints & Gas Detection Guide

3) “10% LEL” Safety Table (Stop-Work Thresholds)

One of the most-cited rules in gas safety is 10% LEL—especially in confined spaces and hot-work planning.

OSHA shipyard guidance states:

- atmospheres at or above 10% LEL are considered hazardous in confined spaces

- but below 10% LEL is not necessarily safe

Practical %LEL Action Table (Common Two-Stage Logic)

| Reading | Typical meaning | Typical response |

|---|---|---|

| 0–9% LEL | below the 10% warning threshold | investigate sources, trend monitoring, ensure ventilation works |

| ≥10% LEL | hazardous in confined-space contexts | stop work, increase ventilation, isolate fuel, re-test |

| 20–40% LEL | high hazard | shutdown/interlocks, evacuate area, emergency response |

| ≥100% LEL | ignition threshold reached | immediate extreme hazard, control ignition sources & evacuate |

(Exact setpoints depend on codes, site risk assessment, and equipment design—but the 10% concept is repeatedly emphasized in OSHA guidance.)

4) Exposure Limits Table (PEL / REL / TLV + TWA / STEL / Ceiling)

Gas safety isn’t only about explosions—many gases are primarily toxic.

You’ll commonly see three “families” of occupational exposure limits (OELs):

OSHA provides annotated tables that compare these limits side-by-side.

TWA vs STEL vs Ceiling

- TWA: time-weighted average (typically 8-hour)

- STEL: short-term exposure limit (typically 15-minute)

- Ceiling (C): should not be exceeded at any time

ACGIH explains how STEL relates to TWA (short duration exposures, limited frequency, with spacing between events).

5) IDLH Table (Emergency / Escape / Respirator-Critical)

IDLH (Immediately Dangerous to Life or Health) is used for escape planning and respirator selection logic in high-risk atmospheres.

NIOSH states IDLH values are intended to help ensure workers can escape if respiratory protection fails and to define maximum conditions requiring the highest reliability breathing apparatus.

Sample IDLH Table (Common Gases)

| Gas | IDLH |

|---|---|

| Carbon monoxide (CO) | 1,200 ppm |

| Chlorine (Cl₂) | 10 ppm |

| Hydrogen sulfide (H₂S) | 100 ppm |

| Carbon dioxide (CO₂) | 40,000 ppm |

These example IDLH values come directly from the NIOSH IDLH table.

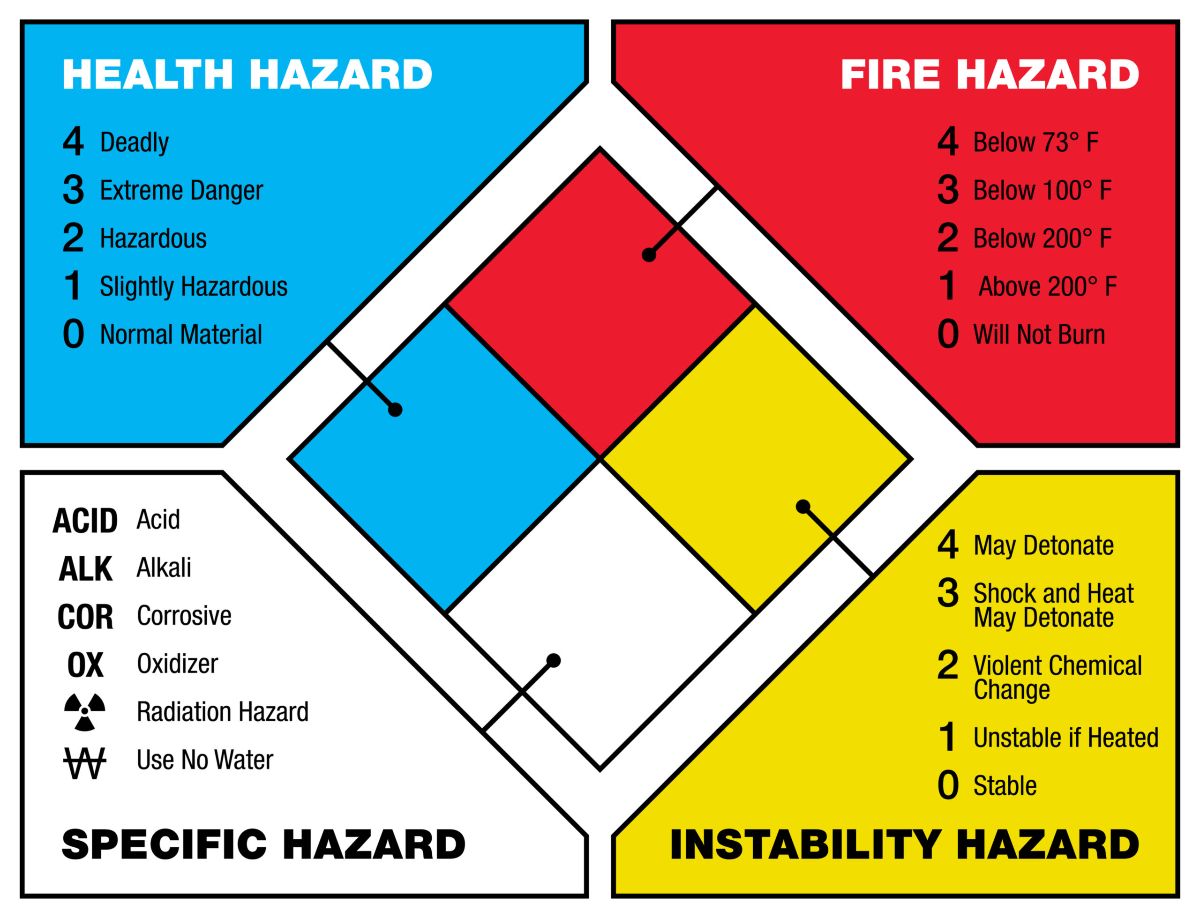

6) NFPA 704 “Diamond” Table (Fast Hazard Communication)

The NFPA 704 diamond is used for rapid hazard recognition (especially by emergency responders). It uses:

- Red = flammability

- Blue = health

- Yellow = instability/reactivity

- White = special hazards

Many NFPA explainers describe the 0–4 severity scale for each colored quadrant.

NFPA 704 Mini-Table (What “0–4” generally means)

| Rating | General meaning |

|---|---|

| 0 | minimal hazard |

| 1 | slight hazard |

| 2 | moderate hazard |

| 3 | serious hazard |

| 4 | severe/extreme hazard |

(Always use the official NFPA guidance or your site’s HazMat program for the precise definitions used in audits/emergency planning.)

7) Detector Placement & Gas Behavior Table (High vs Low Mounting)

A major “table topic” across top gas-safety pages is where to mount detectors. One simple rule is based on relative vapor density:

- Lighter than air (e.g., methane) tends to rise

- Heavier than air (e.g., propane/LPG) tends to sink

Official chemical databases and pocket guides often include vapor density/relative gas density fields alongside LEL/UEL, which helps drive installation guidance.

Placement Table (Quick Rule of Thumb)

| Gas type | Examples | Typical detector placement |

|---|---|---|

| Lighter-than-air | methane, hydrogen | high points / near ceiling |

| Heavier-than-air | propane, butane, LPG | low points / near floor, pits |

| Near-air-density | some VOCs | follow airflow, leak sources, ventilation patterns |

Turn Gas-Safety Tables Into a Product Feature

If you manufacture gas alarms, HVAC safety monitors, industrial transmitters, or IoT gateways, “gas-safety tables” aren’t just content—they’re also a product UX feature:

- show %LEL clearly with staged alarms

- include oxygen thresholds and toxic exposure references where relevant

- support calibration gas selection and self-test/bump-test reminders

For sensor integration, you can embed combustible sensing in your product design using multi-technology options (catalytic / IR / MOS). Winsen supports OEM/ODM customization, selection help, and integration guidance:

Winsen combustible sensor options:

https://www.winsen-sensor.com/combusitable-sensor/

FAQs

What are gas-safety tables?

They are standardized reference charts used for safe gas handling—typically covering oxygen thresholds, explosive limits (LEL/UEL), exposure limits (TWA/STEL/C), IDLH values, and hazard labeling.

What is the most important table for confined spaces?

Most programs start with oxygen %, then check flammability (%LEL), then toxic exposure as needed. OSHA defines oxygen-deficient as <19.5% and oxygen-enriched as >23.5%.

Why is “10% LEL” used so often?

OSHA guidance treats atmospheres at or above 10% LEL as hazardous in confined spaces, while also cautioning that below 10% is not automatically safe.

Where can I find reliable IDLH tables?

NIOSH publishes an official IDLH table and explains how IDLH values are used for escape and respirator selection criteria.