Laser PM Sensors (PM1.0 / PM2.5 / PM10) — Principles, Specifications, Applications & OEM Integration

1) What Is a Laser PM Sensor?

A laser PM sensor measures airborne particles via light scattering. As particles pass a laser beam inside an optical chamber, a photodiode detects scattered light pulses whose intensity relates to particle size and quantity. Embedded algorithms transform pulses into size-binned counts and mass concentrations (PM1.0/2.5/10). Compared with infrared (IR) dust sensors, laser PM sensors offer lower minimum detectable size (~0.3 μm), better fine-particle fidelity, and often faster, more stable response—ideal for PM2.5-driven AQI and purifier auto-control.

2) How It Works (from photons to PM values)

- Controlled airflow: A micro-fan or well-designed convection channel moves air through a blackened, anti-reflection chamber.

- Laser illumination: A laser diode generates a narrow, stable beam.

- Mie scattering: Each particle scatters light; pulse amplitude ~ size³ within the optical response window.

- Pulse classification: Analog front-end + DSP classify pulses into size bins and counts.

- Mass estimation: Counts are mapped to µg/m³ using assumed particle density (ρ) and shape factor (k), plus flow/collection efficiency models.

- Compensation: Temperature/RH inputs correct hygroscopic growth and electronics drift.

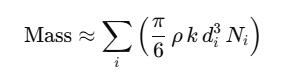

Mass conversion (conceptual):

where (N_i) is particle count in size bin (i), (d_i) is representative diameter.

Winsen Laser PM Sensors

ZH09 Laser dust sensor

- PM1.0,PM2.5,PM10

- 0-100 μg/m³:±15μg/m³ 101-1000 μg /m³: ± 15% Reading (Test Condition: 25 ± 2 ℃, 50 ± 10%RH, Grimm, Cigarette, GBT18801-2015

- Read More

3) Key Advantages of Winsen Laser PM

- Fine-particle sensitivity: Reliable detection to ~0.3 μm, strengthening PM2.5 and smoke event fidelity.

- Fast dynamics: Typical T90 ≤ 10 s, enabling responsive purifier control and real-time dashboards.

- Rich outputs: PM1.0/2.5/10 mass plus number counts/size bins (model-dependent) for advanced analytics.

- Stable baseline: Optimized optics and flow reduce drift; self-diagnostics monitor fan/laser/contamination.

- Compact & integrable: UART/I²C protocols, 3.3–5 V logic compatibility, small footprints for embedded design.

4) What to Specify (so the right module is selected)

- Metrics: PM1.0/2.5/10 in µg/m³; request number counts & size bins if needed for research/analytics.

- Resolution & LOD: 1 µg/m³ resolution typical; verify minimum bin (≥0.3 μm).

- Response time: Target ≤ 10 s T90 for real-time control (smoke/cooking events).

- Accuracy/linearity: Specify ±(% of rdg + µg/m³) over your temperature/RH window and aerosol class.

- Operating window: −10…+50 °C (typ.), 0–95 %RH non-condensing; altitude/pressure range if applicable.

- Interfaces: UART / I²C (primary), optional PWM/analog.

- Power profile: 5 V or 3.3–5 V logic; note peak current during fan spin-up/laser start.

- Self-diagnostics: Fan tach, laser current monitor, optics contamination flag.

5) Applications & Recommended Setups

Air Purifiers & Premium IAQ Monitors

- Goal: Stable PM2.5 for auto-mode; transparent AQI.

- Setup: Laser PM with counts, integrated RH/T, and fan-safe firmware (spike + smoothing).

- Tip: Map counts to filter-life models, not only mass.

Smart Buildings & BMS

- Goal: Demand-controlled ventilation/filtration and IAQ compliance logging.

- Setup: Laser PM via UART/I²C → Modbus/BACnet gateway; log 1–60 s intervals.

- Tip: Co-monitor CO₂ / TVOC / RH/T to avoid misattribution (e.g., cooking aerosols vs occupancy).

Perimeter / Wildfire Smoke Detection

- Goal: Early smoke alerts with low false alarms.

- Setup: Weather hood, hydrophobic mesh, periodic self-clean pulse; rate-of-rise + absolute alarm logic.

- Tip: Seasonally tune aerosol factors; validate against a reference node.

Light-Industrial / Warehouse Dust Trending

- Goal: Alarm on excessive dust near lines/packaging.

- Setup: Laser PM with pre-filter, maintenance flagging; relay output via the host MCU.

- Tip: Use minimum on-time for fans/relays to prevent chatter.

6) Selection Checklist

- Metrics needed: Mass only or mass + counts/size bins

- Targets: Event detection vs long-term trend; required T90

- Environment: RH/temperature extremes, condensation risk, dust load

- Interface: UART / I²C (and PWM/analog if needed), protocol framing and checksum

- Mechanical: Mounting space, inlet protection, service access for cleaning

- Compensation: RH/T source (onboard or external) and aerosol factor strategy

- Compliance: CE/UKCA, RoHS/REACH; EMC design per EN 61326

- Maintenance: Self-clean routine, optics fouling indicator, recommended interval

7) FAQs

Q1. Are laser PM sensors regulatory-grade?

They provide near-real-time trends strongly correlated to reference methods when RH-compensated and aerosol-tuned, but formal compliance still relies on gravimetric reference.

Q2. Why do values spike during cooking/cleaning?

Oil mist and detergent aerosols scatter strongly; use event masking, user prompts, and rate-of-rise logic.

Q3. Do I need number counts?

Counts add value for smoke analytics, filter modeling, and research. For basic AQI or auto-mode, mass outputs may suffice.

Q4. How to manage high humidity?

Avoid condensation; use RH compensation and consider a mild inlet anti-fog strategy.

Q5. What about maintenance?

Design for quick optics access or rely on contamination indicators and fan bursts to extend intervals.

8) Why Choose Winsen

- Fine-particle fidelity: Laser optics tuned for PM1.0/PM2.5 sensitivity with robust flow control.

- Integration-ready: UART/I²C, compact form factors, clear protocols, and sample code.

- Quality & scale: Batch consistency, outgoing tests, and engineering support for RH compensation and aerosol calibration.

- Customization: Output mapping, alarm thresholds, enclosure adaptations, and OEM branding.

Talk to Our Engineers

Share your target market, interface/power, enclosure constraints, and AQI/analytics goals. We’ll recommend an optimal Winsen Laser PM sensor variant and provide evaluation kits, protocols, and mechanical references to accelerate your launch.