Combustible Gas Safety Guide, LEL Explained, Detector Placement, and Sensor Selection

Combustible gas is any gas that can ignite and burn when mixed with air (oxygen) in the right concentration range. In homes, it usually means natural gas (methane) or LPG (propane/butane). In industry, it can include hydrogen, ethylene, carbon monoxide (flammable), and many others.

Because combustible gas leaks can escalate from a small odor to a flash fire or explosion, detection is one of the most cost-effective safety upgrades you can make—especially when paired with automatic ventilation and shutoff valves.

What Is Combustible Gas?

A gas is “combustible” (or flammable) if it can form an ignitable mixture with air and burn when an ignition source is present (spark, hot surface, static electricity, open flame).

Typical combustible gases include:

- Methane (CH₄) – natural gas, biogas

- Propane (C₃H₈) / Butane (C₄H₁₀) – LPG cylinders, cooking fuel

- Hydrogen (H₂) – battery rooms, hydrogen energy, some UPS systems

- Ethylene (C₂H₄) – petrochemical processes

- Carbon monoxide (CO) – toxic and combustible (often monitored primarily for toxicity)

LEL and UEL Explained (Why %LEL Is the Most Common Output)

Combustible gas risk is usually measured in %LEL:

- LEL (Lower Explosive Limit): the minimum concentration (%) in air that can ignite

- UEL (Upper Explosive Limit): the maximum concentration (%) in air that can ignite

- Between LEL and UEL is the flammable range

Example (approximate, varies by reference conditions):

- Methane: LEL ~5% vol, UEL ~15% vol

- Propane: LEL ~2.1% vol, UEL ~9.5% vol

- Hydrogen: LEL ~4% vol, UEL ~75% vol (very wide range)

Because the “danger zone” starts at the LEL, most detectors are designed to alarm well below it (commonly 10–25% LEL depending on codes and risk strategy).

Practical takeaway: %LEL is a safety language that helps you set alarms, control ventilation, and trigger shutdown logic in a consistent way across different gases.

Common Combustible Gases: Key Properties That Affect Sensor Choice & Placement

| Gas | Typical Source | LEL (approx) | Relative Density vs Air* | Placement Hint |

|---|---|---|---|---|

| Methane (Natural Gas) | boilers, kitchens, pipelines | 5% vol | ~0.55 (lighter) | near ceiling / high points |

| Propane (LPG) | cylinders, forklifts, cooking | 2.1% vol | ~1.5 (heavier) | near floor / low points |

| Butane | LPG blends, lighters | 1.8% vol | ~2.0 (heavier) | near floor / pits |

| Hydrogen | battery rooms, H₂ storage | 4% vol | ~0.07 (much lighter) | highest points, near roof |

| Ethylene | petrochemical | 2.7% vol | ~0.97 (similar) | breathing zone + airflow study |

*Relative density matters because leaked gas tends to rise or sink depending on density and airflow.

How Combustible Gas Detectors Work (Sensor Technologies)

Different environments need different sensing principles. Here are the most common options:

1) Catalytic Combustion (Pellistor) Sensors

How it works: gas oxidizes on a heated catalyst bead → heat change → signal proportional to combustible concentration.

.jpg)

Pros

- Good all-around solution for many combustible gases

- Mature, widely used in industry

- Works well for %LEL measurement

Cons

- Needs oxygen to operate correctly

- Can be affected by silicone poisoning, lead compounds, sulfur compounds

- Higher power than some alternatives

MR007 CH4 Methane C3H8 Propane Gas Sensor

- CH4 methane C3H8 propane, combustible gas, natural gas, coal gas, LPG gas

- 0~100 LEL

- Read More

ZC13 Methane CH4 Sensor Module for Home Gas Safety

- methane CH4, natural gas, flammable gas

- 1%-25%LEL,Resolution100ppm

- Read More

MC119 Catalytic Flammable Gas Sensor

- hydrogen, acetylene, gasoline, VOC such as alcohol, ketone, benzene.

- 0-100%LEL Anti-explosion Mark:ExdibⅠ

- Read More

ZC08-CH4 Methane Sensor Module for Home Natural Gas Leakage

- methane CH4, natural gas, flammable gas

- 1%-20%LEL,Resolution100ppm

- Read More

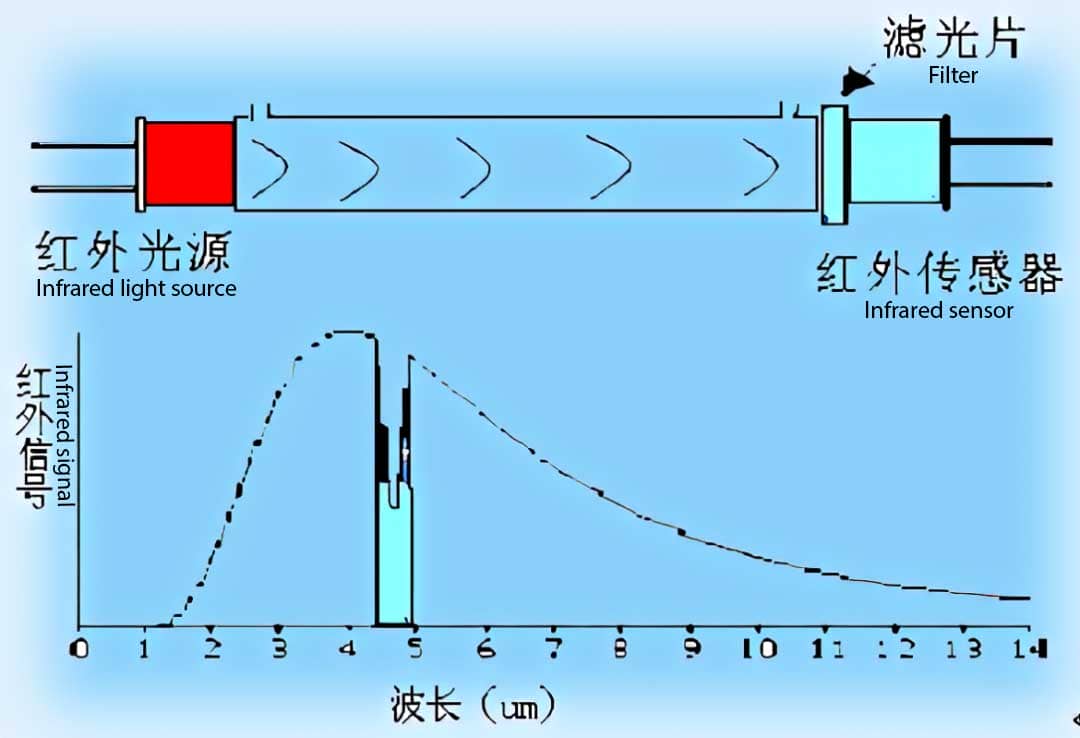

2) Infrared (NDIR) Combustible Gas Sensors

How it works: hydrocarbons absorb IR light at specific wavelengths → absorption correlates to concentration.

Pros

- Resistant to catalyst poisoning (no bead catalyst)

- Stable for hydrocarbon gases (methane, propane, butane)

- Often longer life / lower drift

Cons

- Not ideal for hydrogen (H₂ does not absorb IR strongly)

- Can be higher cost depending on design

3) MOS (Semiconductor) Sensors

How it works: gas changes conductivity of a heated metal-oxide surface.

Pros

- Compact, cost-effective, good for consumer/residential alarms

- Fast response for many gases

Cons

- Cross-sensitivity to VOCs, humidity/temperature effects

- Typically not as selective without compensation algorithms

MPn-4C CH4 Methane Flammable Gas Sensor

- CH4, Methane, Natural gas, marsh gas

- 300~10000ppm (methane, natural gas)

- Read More

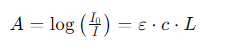

4) TDLAS Laser Methane(CH4) Sensor

TDLAS is based on the absorption of laser light by gas molecules. When a tunable diode laser emits light at a specific wavelength that corresponds to an absorption line of a gas molecule, the gas absorbs a portion of the light. By tuning the laser across the absorption line and measuring the intensity of the transmitted light, the concentration of the gas can be determined. The Beer-Lambert law describes the relationship between the absorbance and the concentration of the absorbing species:

How to Choose the Right Combustible Gas Sensor

Before you buy a detector or integrate a sensor into your product, answer these:

- Target gas(es): methane? propane? hydrogen? mixed hydrocarbons?

- Measurement unit: %LEL, ppm, %vol (LEL is most common for safety)

- Environment: indoor/outdoor, temperature range, humidity, dust/oil mist

- Interferences: silicone vapors, solvents, H₂S, exhaust, cleaning chemicals

- Response requirements: T90 response time, alarm latency tolerance

- Power budget: battery, mains, or 24V industrial loop

- Output & integration: analog (4–20 mA), RS485/Modbus, relay, UART/I²C

- Compliance needs: ATEX/IECEx/UL

- Maintenance plan: calibration/bump-test accessibility and schedule

- Total cost of ownership: sensor life + calibration labor + downtime risk

Where to Install Combustible Gas Detectors

Correct placement is the difference between “installed” and “effective”.

Placement by Gas Density

- Lighter-than-air gases (methane, hydrogen): mount high (near ceiling, roof beams, top of enclosures)

- Heavier-than-air gases (propane, butane): mount low (near floor, pits, trenches, low corners)

- Similar to air (ethylene): consider airflow patterns, mount near likely leak paths

Practical placement tips

- Install near probable leak sources: valves, regulators, joints, meters, burners, compressors

- Avoid dead zones: corners with no airflow, behind doors, inside sealed cabinets unless sampled

- Don’t mount directly in front of vents where fresh air dilutes the leak before detection

- In mechanical rooms, consider multiple sensors: high + low if gases vary or unknown

Alarm Setpoints and Control Logic (Typical Best Practice)

Most safety systems use two alarm levels:

- Low alarm: early warning → turn on ventilation, notify operators

- High alarm: urgent → shut off gas supply, stop ignition sources, evacuate response

Common practice is to set alarms somewhere like 10–20% LEL (low) and 20–40% LEL (high) depending on regulations, site risk assessment, and process needs.

Recommended approach: follow your local code requirements and conduct a hazard analysis for the space.

Typical Applications Where Combustible Gas Sensors Are Essential

Residential & Commercial Gas Safety

- Kitchens, restaurants, apartment boiler rooms

- Natural gas meters and regulators

- LPG cylinder cabinets and cooking lines

Industrial & Energy

- LNG/LPG storage areas, filling stations

- Compressor rooms, chiller plants, mechanical rooms

- Petrochemical processing areas and pipe racks

- Hydrogen production/storage, battery rooms, fuel cell facilities

Smart Buildings & IoT

- Gas leak detection integrated into BMS/SCADA

- Automated ventilation + shutoff valve systems

- Remote monitoring for facility management teams

Embedding Combustible Sensors Into Your Products

If you manufacture gas alarms and controllers, HVAC safety monitors, smart kitchen systems, industrial transmitters, or IoT gateways for safety monitoring, integrating a reliable combustible gas sensor can instantly elevate your product with stronger safety performance, easier compliance planning, and better market differentiation.

What to look for in a sensor supplier

-

Multiple sensing principles (catalytic, IR, MOS) to fit different gases, environments, and price tiers

-

Stable production capacity and consistent calibration / quality control

-

Integration-friendly formats (sensor elements, modules, transmitters) to speed up your development cycle

-

Clear technical documentation for compensation, warm-up behavior, drift, and long-term stability

Why Winsen

Winsen provides a broad range of combustible gas sensing solutions and supports OEM/ODM customization, including output/interface options, housing design, and application-specific tuning. Our team can also help with sensor selection, integration guidance, and technical support to shorten your time-to-market.

Tell us your target gas (CH₄/LPG/H₂, etc.), detection range (%LEL/ppm), and application (kitchen, boiler room, HVAC, industrial). We’ll recommend the best sensor approach and provide a tailored solution.

➡️ Explore Winsen Combustible Sensor Options: https://www.winsen-sensor.com/combusitable-sensor/

FAQ

1) What is the difference between combustible gas and toxic gas?

Combustible gas focuses on fire/explosion risk (measured in %LEL). Toxic gas focuses on health risk (often measured in ppm), like CO, H₂S, NH₃.

2) What does %LEL mean?

%LEL is the percentage of the Lower Explosive Limit. 100% LEL means you’ve reached the minimum concentration that can ignite.

3) Is methane heavier than air?

No—methane is lighter than air, so it tends to rise (depending on airflow).

4) Is propane heavier than air?

Yes—propane is heavier than air and tends to accumulate near floors, pits, and low areas.

5) Which sensor is best for natural gas leaks?

For methane/natural gas, common choices include catalytic and infrared (NDIR) depending on environment, power, and stability needs.

6) Can infrared sensors detect hydrogen?

Typically not well. Hydrogen usually requires catalytic or other suitable technologies.

7) Where should I place an LPG gas detector?

Generally low, near the floor and close to potential leak sources—but not in dead-air zones.

8) Do combustible gas detectors require calibration?

Yes. Regular bump testing and periodic calibration are recommended to maintain reliability.

9) What causes catalytic sensors to fail early?

Catalyst poisoning from certain chemicals (e.g., silicone vapors), harsh environments, or repeated high exposure events can reduce sensitivity.

10) How do I connect a gas sensor to my control system?

Common options include relays for alarms, analog outputs (e.g., 4–20 mA), or digital interfaces like RS485/Modbus depending on product design.

11) What’s the best way to reduce false alarms?

Correct placement, choosing the right sensing principle for the environment, compensation algorithms, and proper calibration schedules.