What is refrigerant used for?

Refrigerants are substances used in refrigeration and air conditioning systems to transfer heat and provide cooling. They play a crucial role in the refrigeration cycle by absorbing heat from the surroundings and releasing it elsewhere, allowing for the removal of heat from a particular space or object.

What is the function of refrigerant?

The main purposes and functions of refrigerants are as follows

Cooling

Refrigeration is a process that uses a refrigerant and a refrigeration cycle to extract heat from a space or object. It involves compressing and expanding the refrigerant to create a cooling effect.

Refrigerants are primarily used for cooling purposes in refrigeration and air conditioning systems. They undergo a phase change from a low-pressure gas to a high-pressure liquid and back again, absorbing heat from the environment during evaporation and releasing it during condensation.

Heat Transfer

Refrigerants act as heat transfer mediums, absorbing heat from the area being cooled (such as the interior of a refrigerator or an air-conditioned space) and transferring it to the outside environment. This allows for the removal of heat from a confined space, resulting in lower temperatures.

Temperature Control

By controlling the pressure and temperature of the refrigerant, the cooling capacity of the system can be adjusted to maintain a desired temperature level. This enables the regulation of temperatures in various applications, including commercial, residential, and industrial settings.

Preservation

Refrigerants are essential for preserving perishable goods, such as food and pharmaceuticals, by maintaining low temperatures and preventing spoilage. They enable the creation of refrigerated storage and transportation systems that help extend the shelf life of products.

Comfort and Climate Control

Refrigerants are used in air conditioning systems to cool and dehumidify indoor environments, providing comfort to occupants and controlling humidity levels. This is particularly important in hot and humid climates. It's worth noting that the choice of refrigerant is critical due to environmental considerations.

How to Choose refrigerant?

Environmental Impact: Environmental considerations have become increasingly important in refrigerant selection. Many traditional refrigerants, such as chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs), have been phased out due to their harmful impact on the ozone layer and contribution to global warming. Look for refrigerants with low ozone depletion potential (ODP) and low global warming potential (GWP). Environmentally friendly options include hydrofluorocarbons (HFCs) with low GWP, natural refrigerants like carbon dioxide (CO2), ammonia (NH3), and hydrocarbons.

System Compatibility: Consider the compatibility of the refrigerant with the equipment or system you plan to use. Different refrigerants may have specific requirements in terms of operating pressure, lubrication, materials compatibility, and system design. Ensure that the chosen refrigerant is compatible with the components, seals, and lubricants used in your system.

Efficiency: Energy efficiency is an important factor to consider. Look for refrigerants that provide high cooling capacity and have good thermodynamic properties. The refrigerant should allow the system to achieve optimal performance while minimizing energy consumption, which can lead to cost savings and reduced environmental impact.

Safety: Safety is critical when working with refrigerants. Consider factors such as toxicity, flammability, and chemical stability. Some refrigerants may pose safety risks, especially if mishandled or leaked. Ensure that the chosen refrigerant is safe for the intended application and that proper safety measures are in place during installation, operation, and maintenance.

Regulatory Compliance: Be aware of the local, regional, and international regulations governing refrigerants. Different jurisdictions may have specific requirements and restrictions on the use and handling of certain refrigerants. Ensure that the chosen refrigerant complies with applicable regulations, permits, and certifications.

Availability and Cost: Consider the availability and cost of the refrigerant. Some refrigerants may be more readily available and cost-effective than others. Evaluate the long-term availability and potential price fluctuations of the refrigerant to ensure a stable supply chain.

How to detect refrigerant leaks

Detecting refrigerant leaks is crucial for maintaining the performance, efficiency, and safety of refrigeration and air conditioning systems.

Visual Inspection

Conduct a visual inspection of the system's components, including pipes, fittings, valves, and connections. Look for signs of oil residue, frost or ice buildup, corrosion, or physical damage. These visual indicators may suggest the presence of a refrigerant leak.

Electronic Leak Detectors

Electronic leak detectors are handheld devices that can detect refrigerant leaks by sensing the presence of the gas in the air. These detectors typically use heated diode sensors, ultrasonic sensors, infrared sensors, or corona discharge sensors to detect leaks. Follow the manufacturer's instructions for proper usage and calibration of the device.

Bubble Solution

Bubble solutions, such as soapy water or commercially available leak detection solutions, can be applied to suspected leak points. If there is a refrigerant leak, bubbles will form at the leak site due to gas escaping. This method is commonly used for detecting leaks in fittings, valves, and connections.

Electronic UV Dye Detection

UV dye can be added to the refrigeration system, which will circulate with the refrigerant. A UV lamp or UV light-emitting device can then be used to inspect the system for UV dye fluorescence. UV dye is useful for detecting small and hard-to-find leaks, but it may require additional equipment and cleanup after detection.

Pressure Decay Test

A pressure decay test involves pressurizing the refrigeration system with an inert gas, such as nitrogen, and monitoring the pressure for any significant drops over a period of time. If the pressure decreases, it indicates a potential refrigerant leak. This method requires specialized equipment and is often used for larger systems or during system installation.

Thermal Imaging

Thermal imaging cameras can be used to detect temperature anomalies caused by refrigerant leaks. Refrigerant leaks often result in localized temperature drops, which can be captured by a thermal imaging camera as temperature variations. This method is particularly useful for detecting leaks in large systems or hard-to-reach areas.

It is important to note that refrigerant leaks should be addressed promptly by qualified technicians. Continual refrigerant leakage can lead to reduced system performance, increased energy consumption, environmental impact, and potential safety hazards. Regular maintenance and inspection of refrigeration systems can help identify and address leaks before they become significant issues.

Winsen Refrigeration Sensor

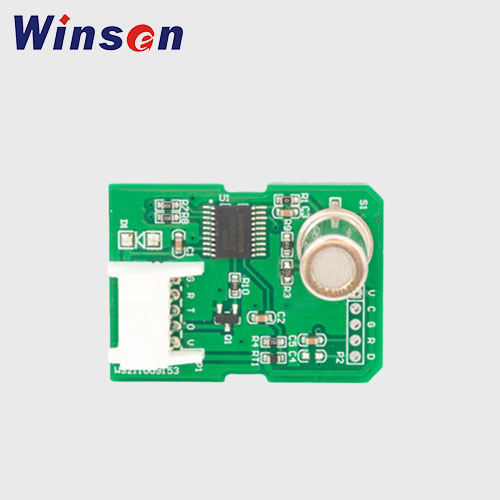

ZP211 Refrigerant gas detection module

- Refrigerant gas R290

- Read More

MH-Z1542B-R32 Refrigerant Sensor Module

- Refrigerant

- 0~5.00% Vol

- Read More

MH-441D NDIR Infrared Refrigerant Sensor

- Refrigerant,R32,R454B,R410A,R134A

- 0~5%VOL

- Read More

MH-441D NDIR Infrared Refrigerant Sensor

- Refrigerant

- 0~5%VOL

- Read More

ZP201 Refrigerant gas detection module

- Refrigerant gas R32

- Alarm value 5000ppm

- Read More

MP510C Refrigerant Gas Sensor

- refrigerant gases:R32、R134a、R410a、R290

- 100-10000ppm

- Read More